Specification MCAC-TSM-2008-02

38 Installation

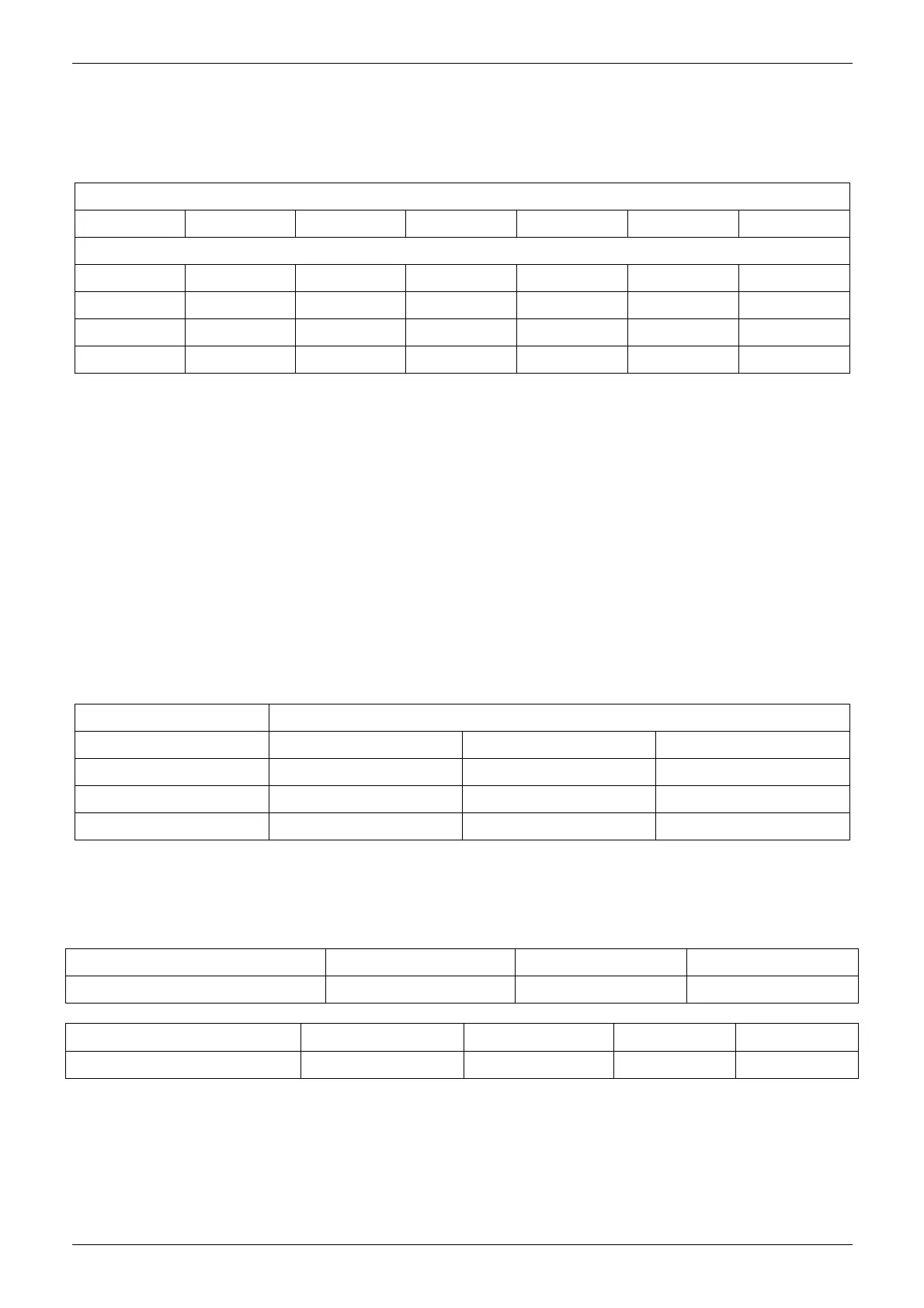

8.1 Ethylene Glycol Solutions

Water and ethylene glycol solutions used as a thermal vector in the place of water reduce the performance

of the unit. Multiply the performance figures by the values given in the following table.

Freezing point (°C)

0 -5 -10 -15 -20 -25

Percentage of ethylene glycol in weight

0 12% 20% 28% 35% 40%

cPf

1 0.98 0.97 0.965 0.96 0.955

cQ

1 1.02 1.04 1.075 1.11 1.14

cdp

1 1.07 1.11 1.18 1.22 1.24

cPf: correction factor refrigerating capacity

cQ: correction factor flow rate

cdp: correction factor pressure drop

Note:

1. During winter leaving the unit unused, please drain water out completely from unit if no antifreeze were

charged into pipeline, or keep power on (at standby or off status) and ensure that water is contained

inside of unit.

2. When ambient temperature lower 5 ,℃ running cooling mode must be charged antifreeze. Refer to

upper parameters for the charged volume.

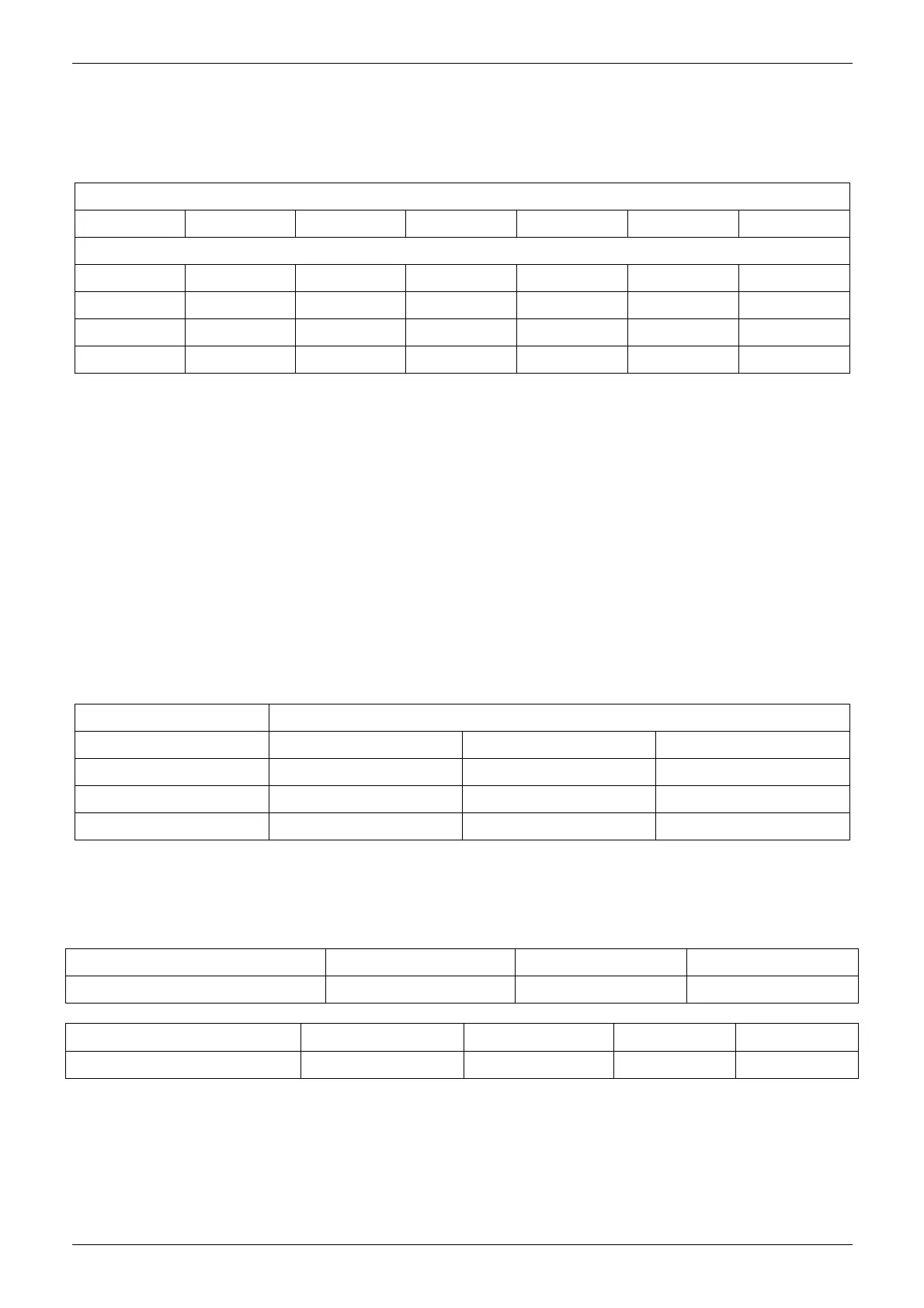

8.2 Fouling Factors

The performance data given refer to conditions with clean evaporator plates (fouling factor=1). For different

fouling factors, multiply the figures in the performance tables by the coefficient given in the following table.

Fouling factors

Evaporator

(m

2

°C/W)

f1 fk1 fx1

4.4×10

-5

- - -

0.86×10

-4

0.96 0.99 0.99

1.72×10

-4

0.93 0.98 0.98

f1 capacity correction factor

fk1 compressor power input correction factor

fx1 total power input correction factor

8.3 Minimum water volume

Model MGC-F05W/N1 MGC-F07W/N1 MGC-F09W/N1

Minimum water content (L) 21 30 38

Model MGC-F10W/(S)N1 MGC-F12W/SN1 MGC-F14W/SN1 MGC-F16W/SN1

Minimum water content (L) 43 50 60 68

Loading...

Loading...