8

2.6.1 NPSH CONSIDERATIONS

Size piping to accommodate peak instantaneous flow. Because of the reciprocating motion of the

pump diaphragm, peak instantaneous ow is approximately equal to 3.14 times the average ow. For

example, a pump rated for 100 L/hr per hour requires piping sufcient for 3.14 x 100 L/hr (314 L/hr.).

To minimize viscous ow losses when handling viscous liquids, it may be necessary to use suction

piping up to four times larger than the size of the suction connection on the pump. If in doubt, contact

your dealer to determine the necessary pipe size.

2.6.2 GENERAL PIPING CONSIDERATIONS

Use extreme care in piping to plastic liquid end pumps with rigid pipe such as PVC. If excessive pipe

stress or vibration is unavoidable, exible connections are recommended.

Use piping materials that will resist corrosion by the liquid being pumped. Use care in selecting materials

to avoid galvanic corrosion at pump liquid end connections.

Use piping heavy enough to withstand maximum pressures. Remove burrs, sharp edges, and debris

from inside piping. Blow out all pipelines before making nal connections to pump.

Because vapor in the liquid end will cause inaccurate pump delivery, piping should be sloped up from

pump suction check to the supply tank to prevent formation of vapor pockets.

When pumping suspended solids (such as slurries), install plugged crosses at all 90°line turns to permit

line cleaning without dismantling piping.

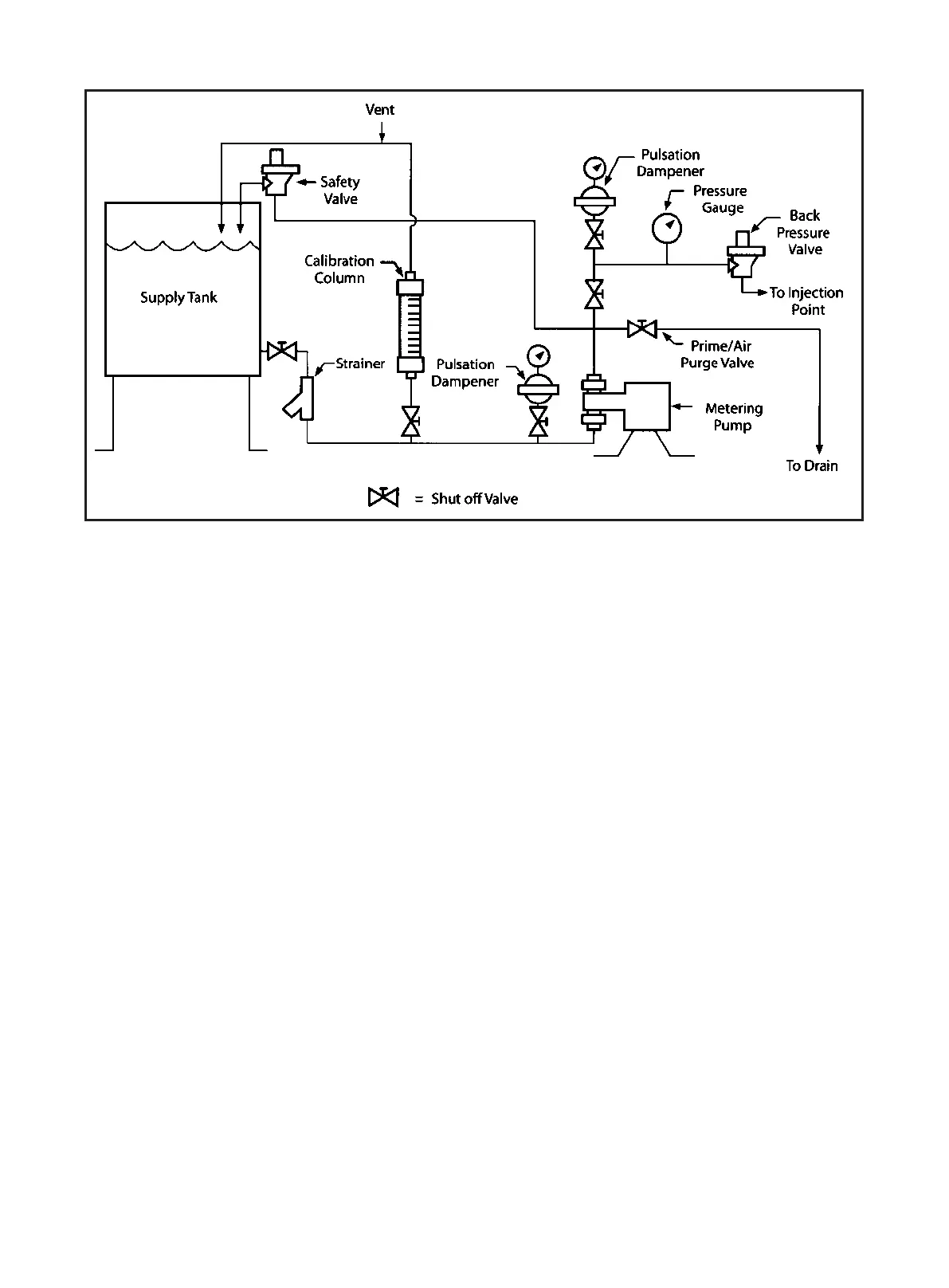

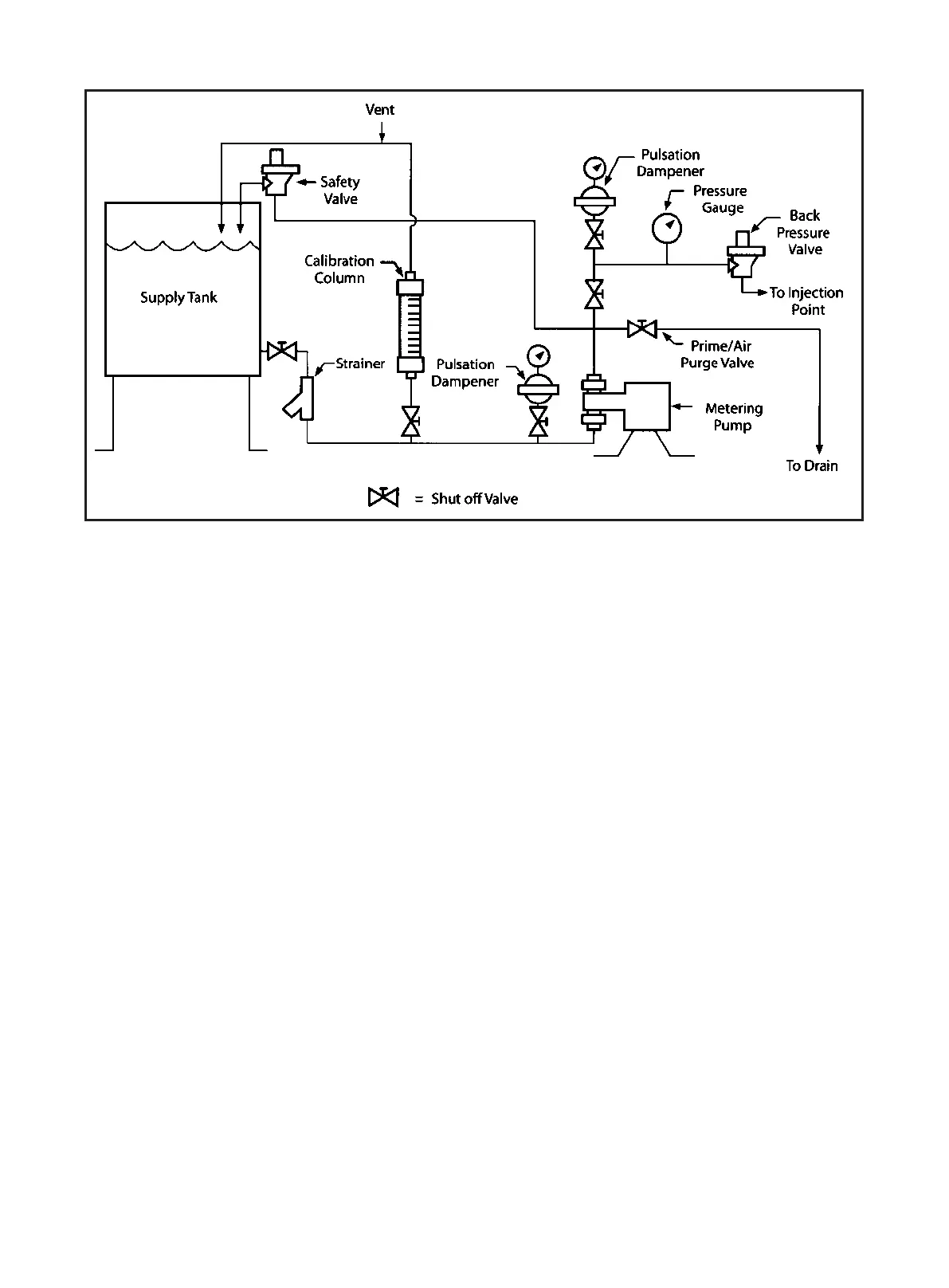

See Figure 2-3 for a typical recommended pump installation scheme.

Figure 2-3:

General Piping

Loading...

Loading...