Main circuit terminals

INSTALLATION AND WIRING

35

2

2.5.4 Applicable cables and wiring length

Select a recommended cable size to ensure that the voltage drop will be 2% or less.

If the wiring distance is long between the inverter and motor, the voltage drop in the main circuit will cause the motor torque to

decrease especially at a low speed.

The following tables for cable selection are one example in the case of a cable of 20 m long used at 440 V power supply.

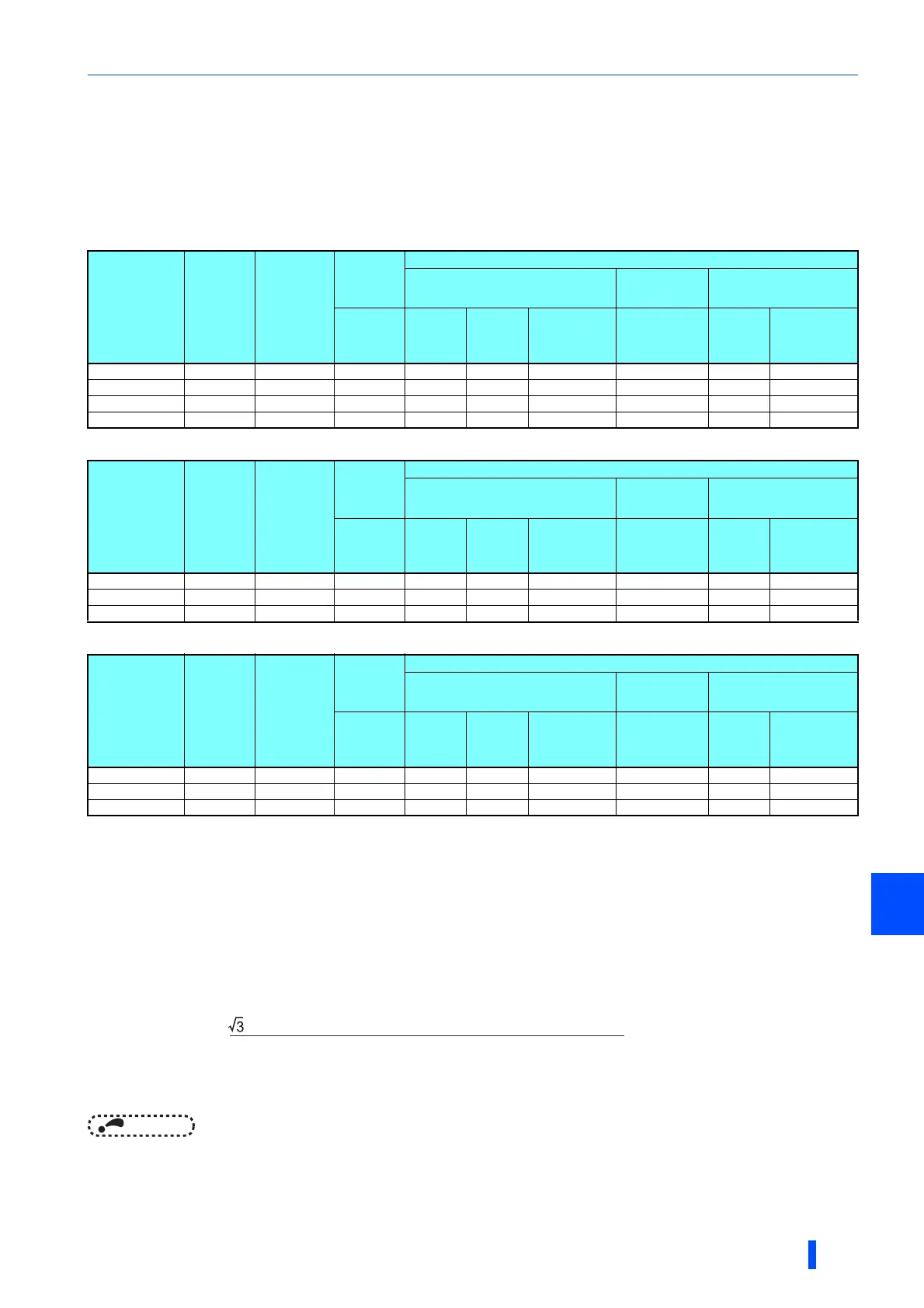

• Single converter unit

• Single inverter (ND rating)

• Single inverter (LD rating)

The gauge of the cable with the continuous maximum permissible temperature of 90°C or higher. (LMFC (heat resistant flexible cross-linked

polyethylene insulated cable), etc.). It assumes a surrounding air temperature of 40°C or lower and in-enclosure wiring.

The recommended cable size is that of the cable (THHN cable) with continuous maximum permissible temperature of 90°C. It assumes a

surrounding air temperature of 40°C or lower and in-enclosure wiring.

(Selection example for use mainly in the United States.)

The cable size is that of the cable (XLPE cable) with continuous maximum permissible temperature of 90°C. It assumes a surrounding air

temperature of 40°C or lower and in-enclosure wiring.

(Selection example for use mainly in Europe.

The terminal screw size indicates the size of a terminal screw for R/L1, S/L2, T/L3, U, V, W, P/+, N/-, and a screw for earthing (grounding).

Screw size for earthing (grounding) is indicated in parentheses.

The line voltage drop can be calculated by the following formula:

Line voltage drop [V]=

Use a larger diameter cable when the wiring distance is long or when it is desired to decrease the voltage drop (torque

reduction) in the low speed range.

NOTE

• Tighten the terminal screw to the specified torque.

A screw that has been tightened too loosely can cause a short circuit or malfunction.

A screw that has been tightened too tightly can cause a short circuit or malfunction due to the unit breakage.

• Use crimp terminals with insulation sleeves to wire the power supply and motor.

Converter

model

FR-CC2-[ ]-P

Terminal

screw

Size

Tightening

Torque

N·m

Crimp

terminal

Cable gauge

HIV cables, etc. (mm

2

)

AWG/MCM

PVC cables, etc.

(mm

2

)

R/L1,

S/L2,

T/L3

R/L1,

S/L2,

T/L3

P/+, N/-

Earthing

(grounding)

cable

R/L1,

S/L2,

T/L3

R/L1,

S/L2,

T/L3

Earthing

(grounding)

cable

H400K M12 (M10) 46 C2-200 2200 2200 100 2400 2185 295

H450K M12 (M10) 46 C2-250 2250 2250 100 2500 2240 2120

H500K M12 (M10) 46 C2-200 3200 3200 2100 2500 2240 2120

H560K M12 (M10) 46 C2-200 3200 3200 2100 3350 3185 2150

Inverter

model

FR-A842-[ ]-P

Terminal

screw

size

Tightening

Torque

N·m

Crimp

terminal

Cable gauge

HIV cables, etc. (mm

2

)

AWG/MCM

PVC cables, etc.

(mm

2

)

U, V, W U, V, W P/+, N/-

Earthing

(grounding)

cable

U, V, W U, V, W

Earthing

(grounding)

cable

09620(400K) M12 (M10) 46 C2-200 2200 2200 100 2400 2185 295

10940(450K) M12 (M10) 46 C2-250 2250 2250 100 2500 2240 2120

12120(500K) M12 (M10) 46 C2-250 2250 3200 2100 2500 2240 2120

Inverter

model

FR-A842-[ ]-P

Terminal

screw

size

Tightening

Torque

N·m

Crimp

terminal

Cable gauge

HIV cables, etc. (mm

2

)

AWG/MCM

PVC cables, etc.

(mm

2

)

U, V, W U, V, W P/+, N/-

Earthing

(grounding)

cable

U, V, W U, V, W

Earthing

(grounding)

cable

09620(400K) M12 (M10) 46 C2-250 2250 2250 100 2500 2240 2120

10940(450K) M12 (M10) 46 C2-250 2250 3200 2100 2500 2240 2120

12120(500K) M12 (M10) 46 C2-200 3200 3200 2100 3350 3185 2150

× wire resistance[mΩ/m] × wiring distance[m] × current[A]

1000

Loading...

Loading...