Parameter settings for a motor with encoder

60

INSTALLATION AND WIRING

2.9 Parameter settings for a motor with encoder

Parameter for the encoder (Pr.359, Pr.369, Pr.852, Pr.853)

• Set the encoder specifications.

The following table shows parameters to be set according to a vector control compatible option to be used.

Parameter settings for the motor under vector control

Pr. Name

Initial

value

Setting

range

Description

359

C141

852

C241

Encoder rotation

direction

1

0

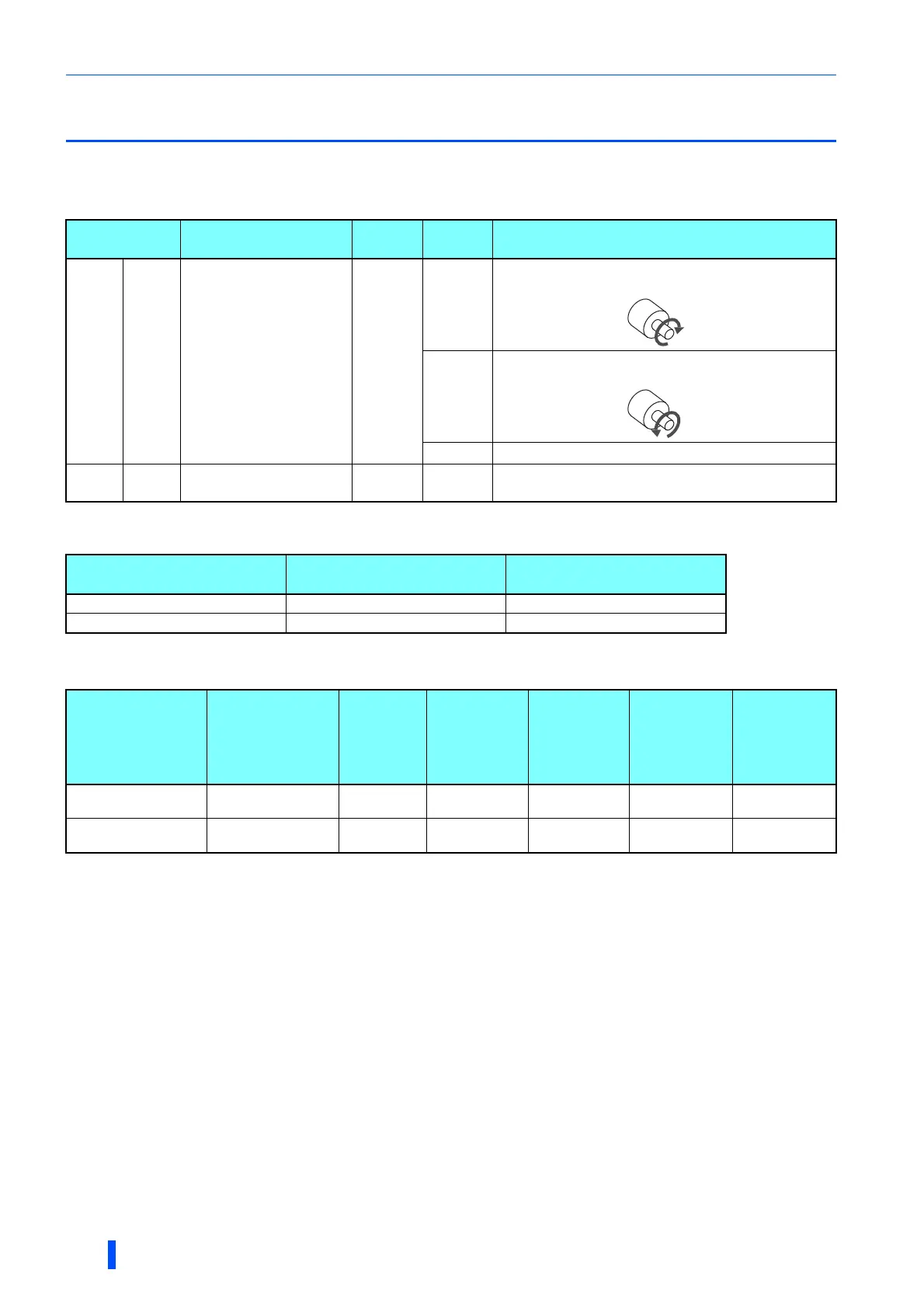

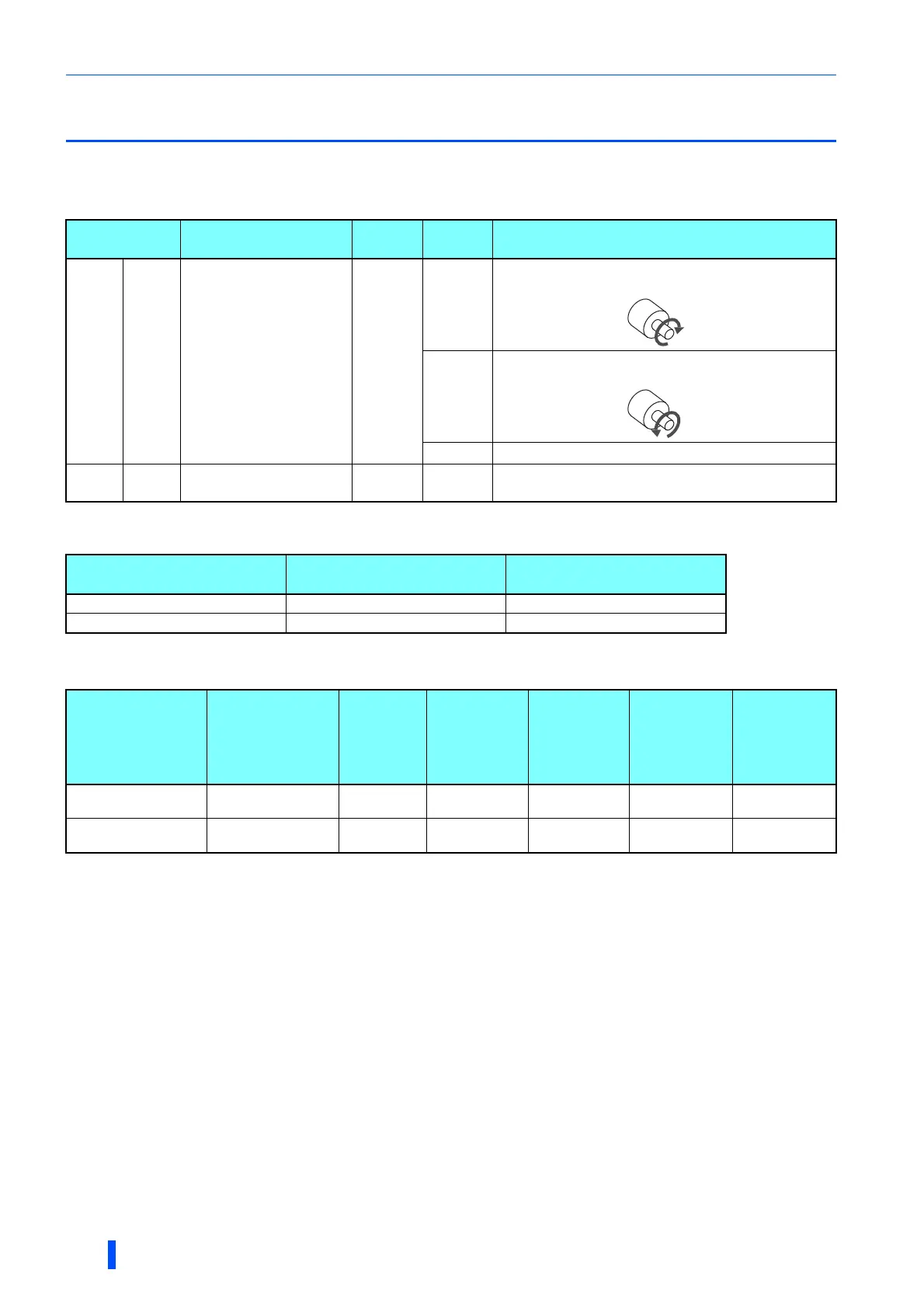

Set when using a motor for which forward rotation (encoder)

is clockwise (CW) viewed from the shaft.

1

Set when using a motor for which forward rotation (encoder)

is counterclockwise (CCW) viewed from the shaft.

100, 101 For manufacturer setting. Do not set.

369

C140

851

C240

Number of encoder

pulses

1024 0 to 4096

Set the number of encoder pulses output.

Set the number of pulses before it is multiplied by 4.

The parameters above can be set when a vector control compatible option is installed.

Item

FR-A8AP/FR-A8AL

parameter

FR-A8TP parameter

Encoder rotation direction Pr.359 Pr.852

Number of detector pulses Pr.369 Pr.851

Motor name

Pr.9

Electronic

thermal O/L relay

Pr.71

Applied

motor

Pr.80

Motor

capacity

Pr.81

Number of

motor poles

Pr.359 /

Pr.852

Encoder

rotation

direction

Pr.369 /

Pr.851

Number of

encoder

pulses

Standard motor Rated motor current 0 (3) Motor capacity

Number of

motor poles

Constant-torque motor Rated motor current 1 (13) Motor capacity

Number of

motor poles

Offline auto tuning is required (Refer to the FR-A800 Instruction Manual (Detailed))

Set this parameter according to the motor.

CW

CCW

Loading...

Loading...