2205Q2JE-HO-S6-N_2020.01.

Chapter 5 Maintenance and Inspection

SCV-series Screw Compressor 5.5 Reassembly

5-42

5.5.7.1 End Clearance Measurement

At this point (i.e., after the thrust bearing block has been fully assembled), measure the end clearance

of the rotor on the discharge side.

In particular, this measurement must be made when the thrust bearing has been replaced. Even if the

same bearing is used, the measurement should be made for verification.

If the measured clearance does not satisfy the range specified in Table 5-9, proper adjustment must be

made.

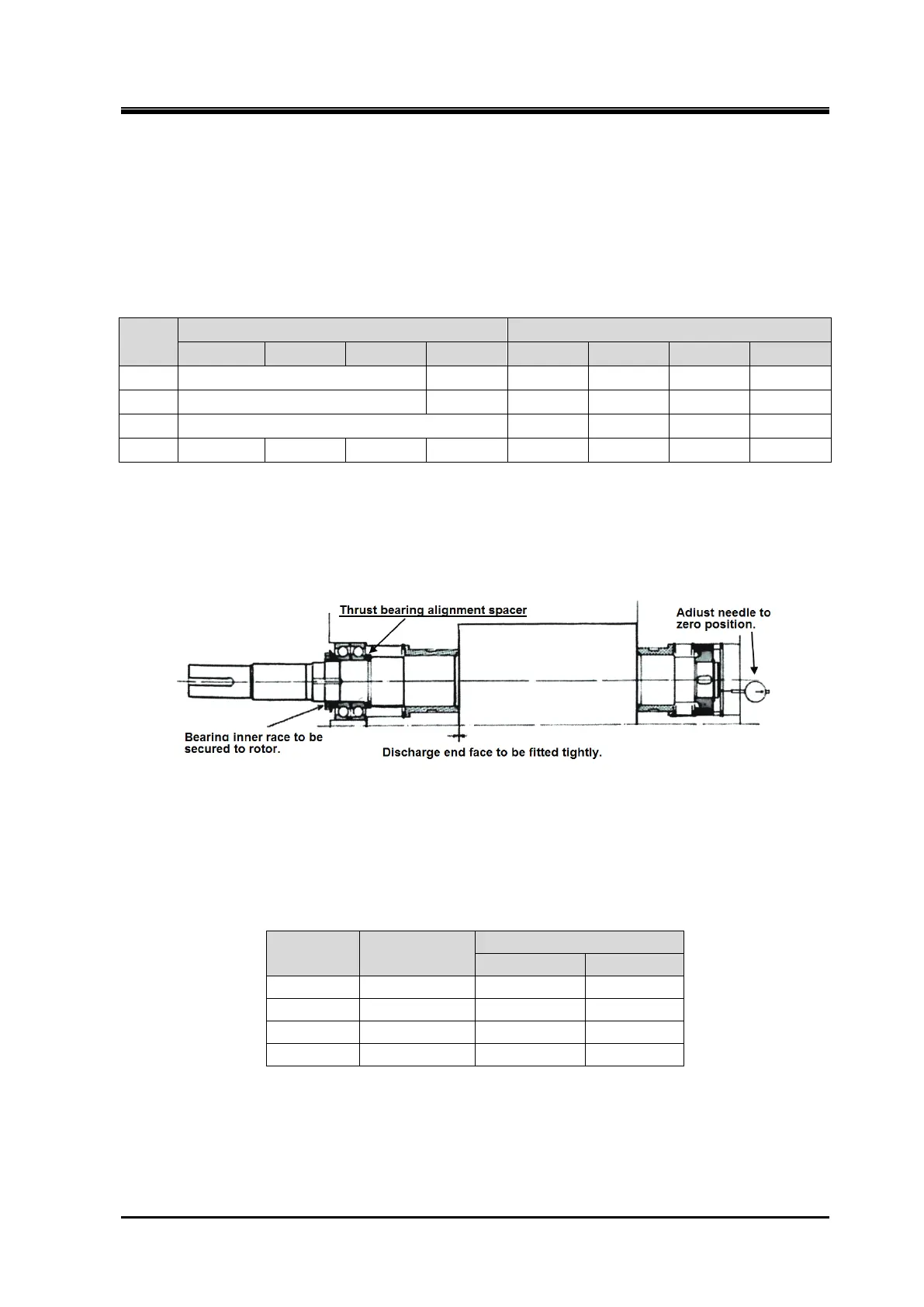

Table 5-9 Specified Limits of End Clearance (unit: mm)

Model

for Single Stage (High Stage) Use

for Booster (Low stage) Use

L LL

L LL

160V** 0.04~0.06 - 0.20~0.22 0.22~0.24 0.24~0.26 -

200V** 0.05~0.07 - 0.26~0.30 0.28~0.32 0.31~0.35 -

250V** 0.08~0.11 0.40~0.44 0.45~0.49 0.50~0.54 0.55~0.59

320V*D 0.17~0.21 0.20~0.24 0.23~0.27 - 0.70~0.76 0.73~0.79 0.77~0.83 -

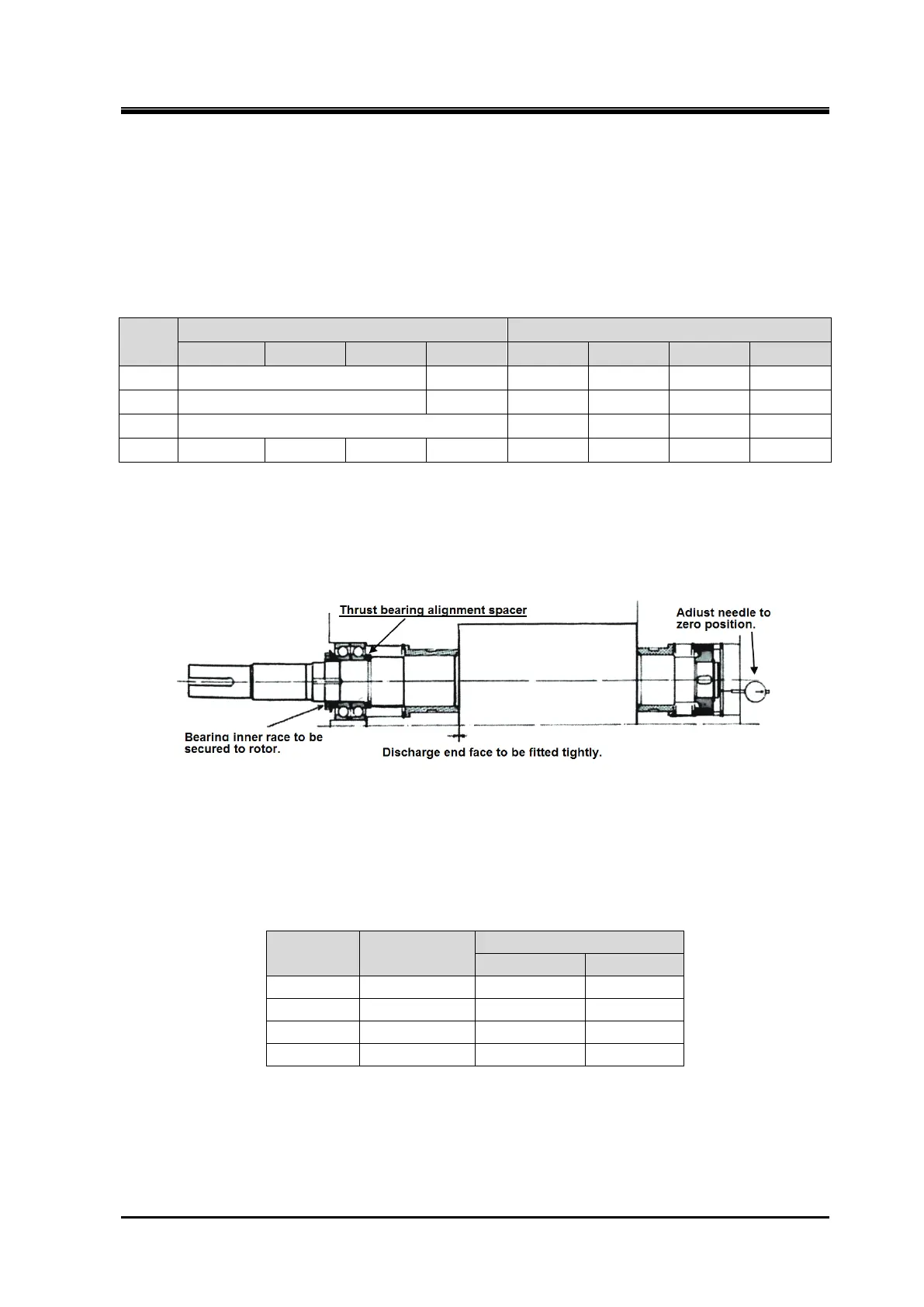

a) For pressing the rotor shaft on to the discharge side, hit the rotor shaft strongly from the suction side

while putting a jig (Teflon block or like).

b) Prepare the thrust bearing gland to be readily mounted. Mount a dial gauge on the axial end of the

rotor, and set the indication needle to zero point while the rotor is fully pressed onto the discharge

end face.

Figure 5-16 End Clearance Measurement Preparation

c) Without inserting the conical spring washer [46], tighten the four fastening bolts [45] of the bearing

gland sequentially and evenly up to the specified tightening torque. Tightening each bolt at once at

the specified torque must be avoided because it will result in uneven tightening. So Tighten with the

procedure shown in 7.3.4.

Table 5-10 Tightening Torques of Thrust Bearing Gland

Model Bolt Size

M10x30 40 400

M12x35 50 500

M20x55 120 1200

d) Then, read the dial gauge indication. This value shows the actual end clearance. If the end

clearance is outside the specified value, perform the adjustment work described in the next section.

If the end clearance is within the specified value, turn the M rotor shaft by hand and confirm the

smooth turning without uneven tightening. And then perform the measurement of the run-out of the

rotor shaft described in next section (3).

Loading...

Loading...