22 – English

12

MAINTENANCE

To ensure constant safety levels a long service life, the system must be serviced regularly: at least every 6 months or after maximum 10,000

movements since the last service.

WARNING! – Maintenance operations must be performed in strict compliance with the safety precautions provided in this man-

ual and according to applicable legislation and standards.

01. Disconnect the power supply to the gearmotor and check the state of deterioration of all the automation’s constituent materials:

pay special attention to erosion and oxidation of structural components. Replace any parts that are not to standard

02. Check the state of wear of moving parts: pinion, rack and all parts of the gate leaf; replace any worn components if necessary

03. Power the gearmotor and run all the tests and checks indicated in Paragraph 6.1 - Testing

11

PRODUCT DISPOSAL

This product constitutes an integral part of the automation and, therefore, must be disposed of together with it.

Similarly to the installation phase, once the product reaches the end of its useful life, the disassembly and scrapping operations must be per-

formed by qualied personnel.

This product is made of various types of materials, some of which can be recycled while others must be scrapped. Seek information on the

recycling and disposal systems envisaged by local regulations in your area for this product category.

WARNING! - Some parts of the product may contain polluting or hazardous substances which, if released into the environment,

constitute serious environmental and health risks.

As indicated by the adjacent symbol, the product may not be disposed of together with domestic waste. Sort the materials for

disposal, according to the methods envisaged by current legislation in your area, or return the product to the retailer when pur-

chasing an equivalent product.

WARNING! - Local regulations may envisage the application of heavy nes in the event of improper disposal of

this product.

10

TROUBLESHOOTING

Table 20 contains useful instructions to help you solve malfunctions or errors that may occur during the installation stage or in case of fault.

Table 20 - Troubleshooting

Problem Solution

The radio transmitter does not control the gate

and the LED on the transmitter does not light

up

Check to see if the transmitter batteries are exhausted and replace them if necessary.

The radio transmitter does not control the gate

and the LED on the transmitter lights up

- Check whether the transmitter has been memorised correctly in the radio receiver.

- Check whether the transmitter emits the radio signal correctly by means of this practical

test: push a button and place the LED on the antenna of a normal radio

(preferably a cheap

one) that is switched on and tuned to 108.5 Mhz FM or as close as possible; a slight crackling

sound should be heard.

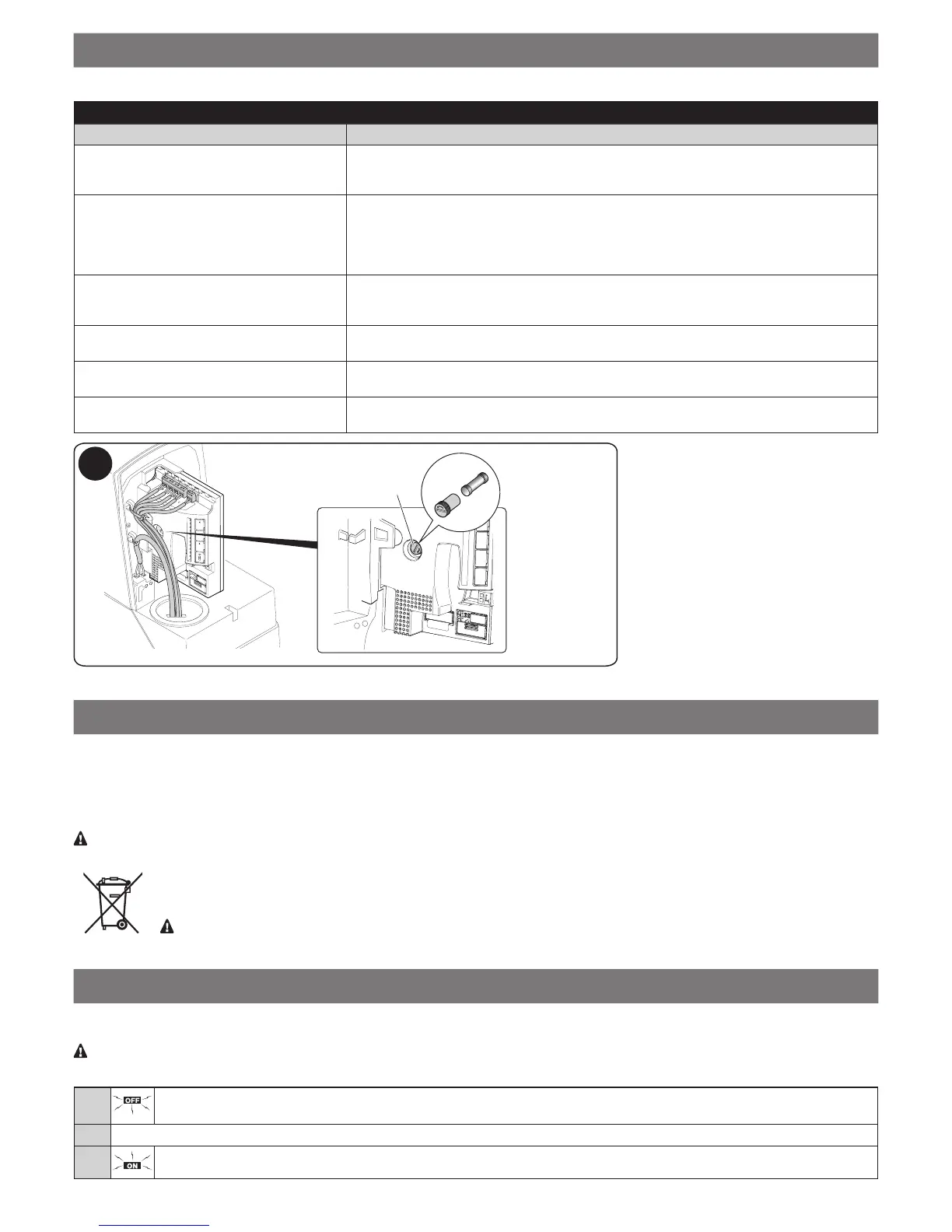

No manoeuvre starts and the OK LED fails to

ash

Check whether the gearmotor is powered at 230 V mains voltage. Check that fuse F2 has

not blown; if it has, identify the reason for the fault then replace it with one of the same current

rating and characteristics (Fig. 11).

No manoeuvre starts and the warning light is

off

Check that the command is actually received. If the command reaches the Step-by-Step

input, the OK LED ashes twice indicating that the command has been received.

The manoeuvre does not start and the courte-

sy light ashes a few times

Count the number of ashes and check them against Table 19.

The manoeuvre starts but it is immediately fol-

lowed by a brief reverse run

The selected force value may be too low to move the gate: check whether there are any ob-

stacles and, if necessary, select a greater force or check whether the limit switch is blocked.

L4(R)

L1L2L3

Close

Open

Stop/Set

Flash

Photo

Photo Test

Stop

GND

SbS

24 V

Aerial

F2

F1

11

Loading...

Loading...