MOTOR

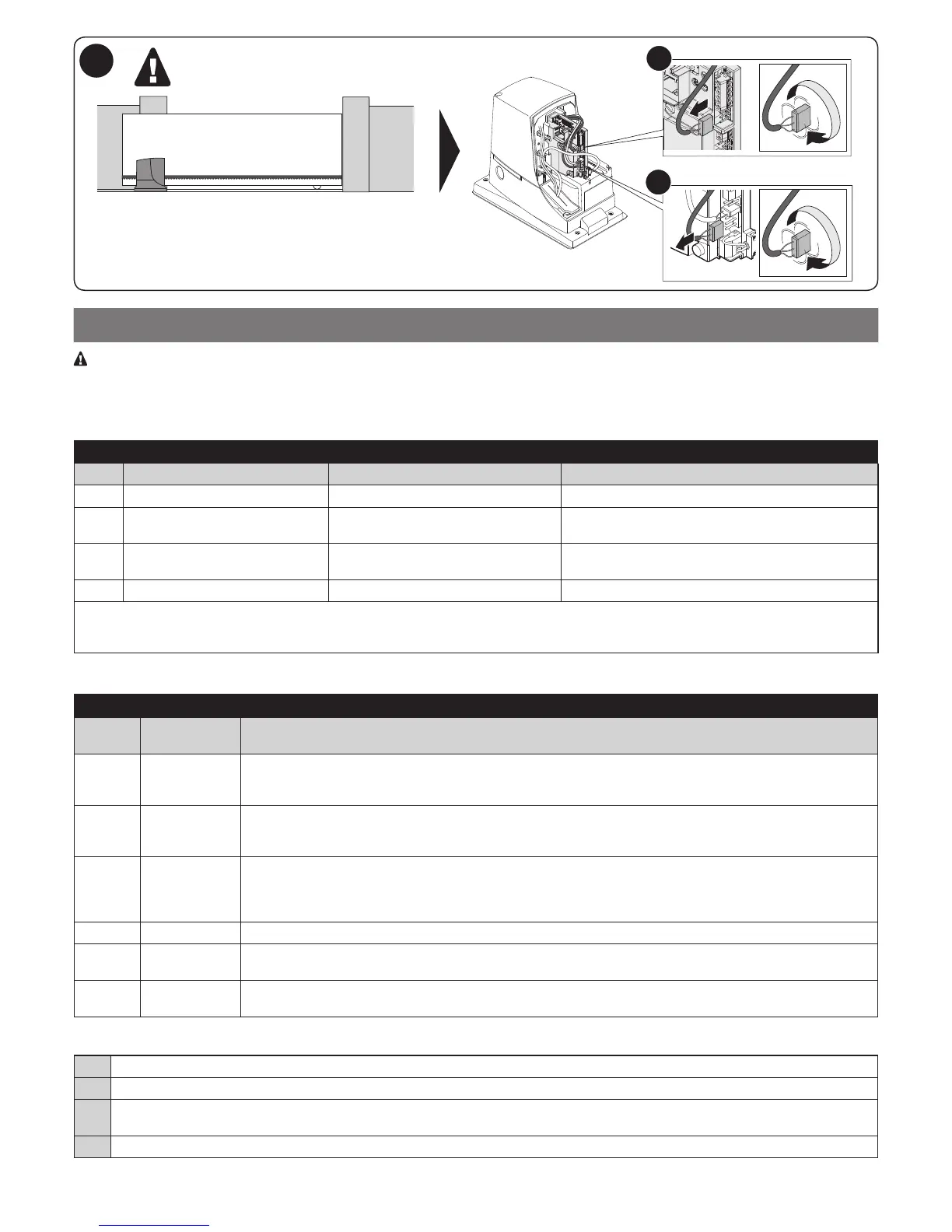

4

ELECTRICAL CONNECTIONS

CAUTION! - All electrical connections must be carried out with the system disconnected from the mains. Incorrect connections

can cause damages to the equipment and injuries to people.

Fig. 2 shows the hookup of a typical installation; g. 7 shows the connections to be made on the control unit.

4.1 - Types of electrical cables

Table 3 - Types of electrical cable (see g. 2)

Connection Type of cable Maximum length

A POWER 3 x 1.5 mm

2

30 m *

B

C

FLASHER WITH AERIAL 1 cable: 2 x 1.5 mm

2

1 shielded RG58 cable

10 m

10 m (< 5 m recommended)

D PHOTOCELLS 1 cable: 2 x 0.25 mm

2

(TX)

1 cable: 4 x 0.25 mm

2

(RX)

30 m

30 m

E - F KEY SWITCH 1 cable: 2 x 0.5 mm

2 **

20 m

* A power supply cable longer than 30 m may be used provided it has a larger gauge, e.g. 3 x 2.5 mm

2

, and that a safety grounding system

is provided near the automation unit.

** The two 2 x 0.5 mm

2

cables can be replaced by a single 4 x 0.5 mm

2

cable.

4.2 - Electrical cable connections: g. 7

Table 4 - Description of electrical connections

Termi-

nals

Function Description

9 - 10 Stop - input for devices that lock or stop the current operation; with appropriate precautions, “Normally Closed” or

“Normally Open” contacts or constant resistance devices can be connected to the input.

Other information on STOP can be found in paragraph 8.1.1 - STOP input

9 - 11 Photo - input for safety devices which when tripped reverse the gate's direction of movement: NC (Normally Closed)

contacts may be used

- for further details, refer to par. 8.1.2 Photocells.

8 - 12 Phototest Every time a manoeuvre is started, the operation of the photocells is checked; the manoeuvre starts if the test

is positive. This is possible using a particular type of connections: the transmitters of the “TX” photocells are

powered separately than the “RX” receivers.

For further details, see paragraph 8.1.2 Photocells.

9 - 13 Step-by-step input for devices which control movement. NO (Normally Open) contacts can be connected

4 - 5 Flashing light - asher output (auto-intermittent)

- when active, the output supplies 230 V~ (120V~ on V1 / motor version)

1 - 2 Aerial - radio receiver aerial input

- aerial integrated into asher; an external aerial can be used if desired

To make the electrical hookup, proceed as described below with reference to g. 7:

01. Open the cover: undo the screw and raise the cover

02. Run the power cable through the hole (leave 20/30 cm of free cable) and connect it to its terminal clamp

03. Run the cables of the equipment to be installed or already present through the provided hole (leave 20/30 cm of free cable) and connect

them to their terminal clamps (see g. 14)

04. Perform the desired programming: chapter 7

Loading...

Loading...