English – 25

Operation manual

(to be given to the nal user)

• When you rst use the automation, the installation technician

must inform you about the origin of the residual risks and you

must take time to read this user manual.

• Make sure to keep this user manual (delivered by the

installation technician) for future reference and for

handover to any further owner of the automation.

• Your automation system is a machine that will faithful-

ly execute your commands; unreasonable or improper

use may generate dangers: do not operate the system

if there are people, animals or objects within its range of

operation.

• Children: automation systems guarantee high levels of

safety and security. They are equipped with detection

devices that prevent movement if people or objects are

in the way, guaranteeing safe and reliable activation.

However, it is advisable to ensure that children do not

play in the vicinity of the automation; remote controls

should always be kept out of reach. It is not a toy!

• Checking the system: in particular all cables, springs

and supports to detect possible imbalance and signs of

wear or damage.

–

Check that the system is safe every month using safety

equipment with sensitive edges.

– Do not use the automation if repairs or adjustments are

required; any fault or an incorrectly balanced gate may

lead to physical injury.

• Malfunctions: if the automation is malfunctioning, shut

off its power supply. Never attempt any repairs; contact

your local installer for assistance.

If the safety devices do not work properly or are out of

service, it is possible TO:

- unlock the gearmotor as described in “Manually un-

locking the gearmotor”, allowing the gate to be opened

and closed manually;

- control the gate anyway in the following way:

01. Activate the gate control with the transmitter. If

the safety devices allow it, the gate will open normally,

otherwise the control must be activated (without

releasing it) again within 3 seconds.

02. After about 2 seconds, the gate will start to move

in “hold-to-run” mode, that is the gate will continue to

move so long as the control is pressed and will stop on

its release.

Modify neither the system nor the automation

programming and adjusting parameters: responsibility

lies with your installer.

– The nal test, periodic maintenance operations and

any repairs must be documented by the person who has

performed them; these documents must remain under

the custody of the owner of the system.

Important: have the system repaired as soon as

possible if the safety equipment is malfunctioning.

Transit is admitted only if the gate is completely open

and stationary.

• Disposal: At the end of the automation’s lifetime, ensure

that it is disposed by qualied personnel and that the

materials are recycled or scrapped according to current

local regulations for this category of product.

• Maintenance: As with all machinery, the automation

requires periodic maintenance to ensure optimal

operation, extended lifetime and complete safety. Arrange

a periodic maintenance schedule with your installation

technician. Nice recommends that maintenance checks

be carried out every six months for normal domestic use,

but this interval may vary depending on the intensity of

use. Only qualied personnel are authorised to carry out

checks, maintenance operations and repairs.

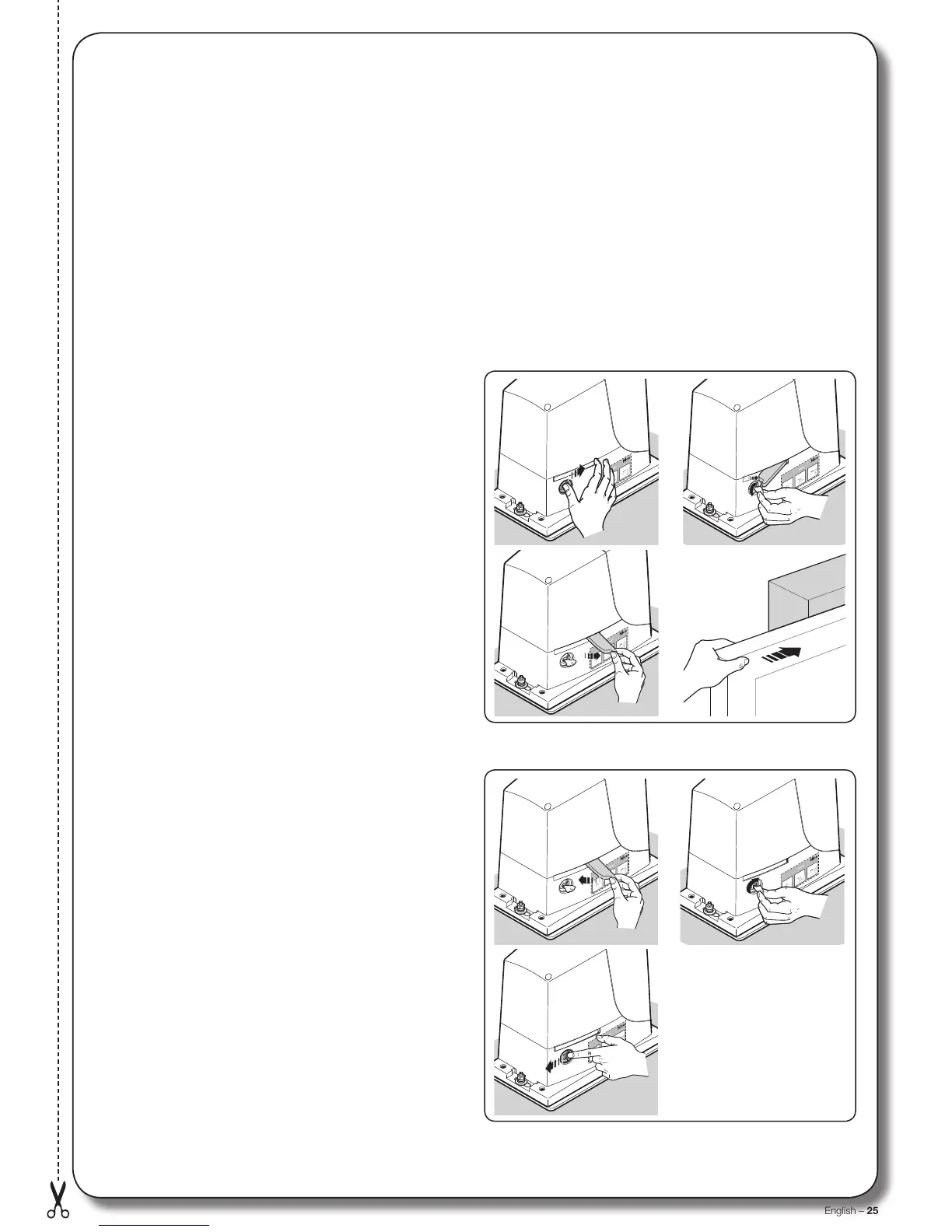

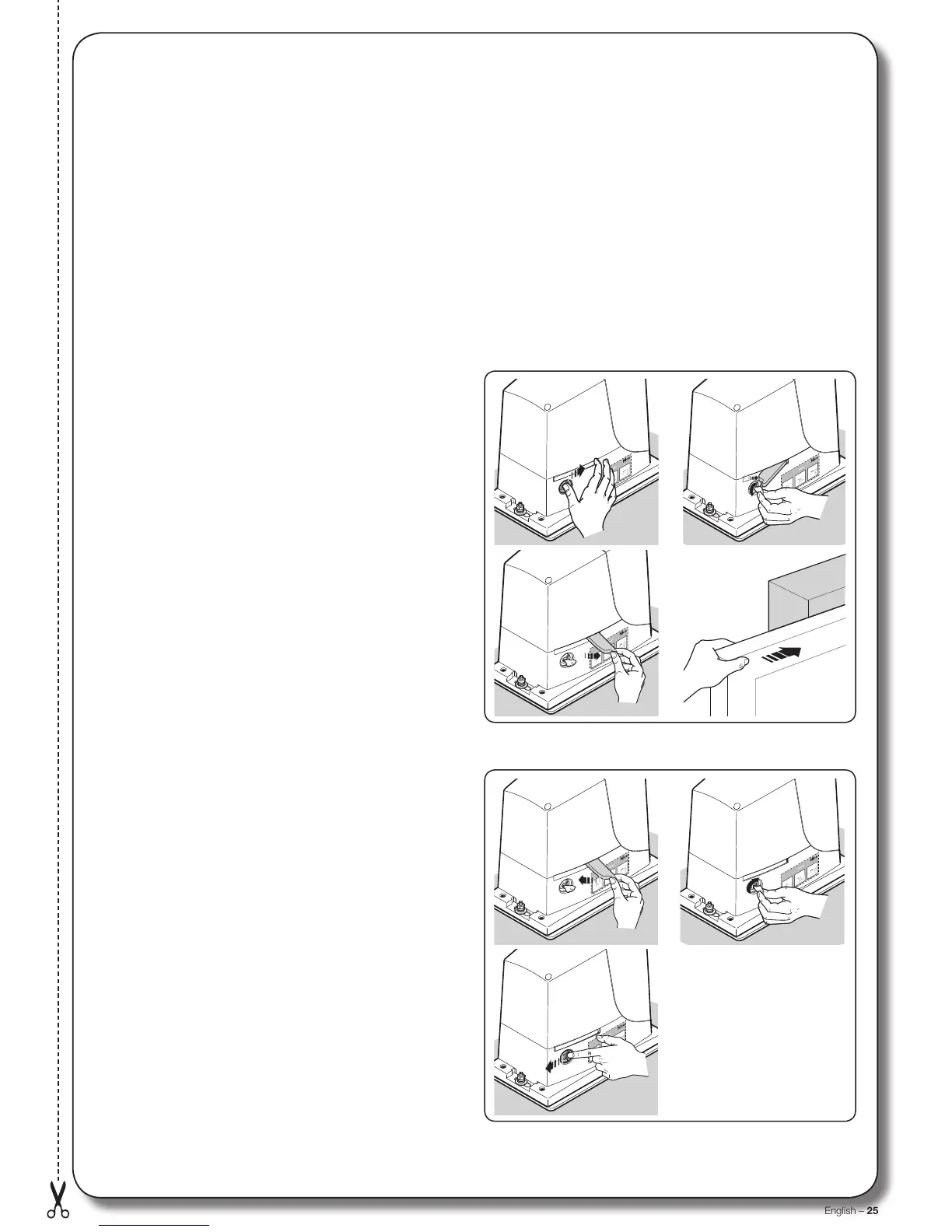

• Manually unlocking the gearmotor

Loading...

Loading...