English – 21

“Move anyway” function

If some safety device is not working or is faulty, it is possible to control and move the gate anyway in “Hold-to-run” mode. For further details,

please refer to the tearout insert “USER GUIDE” (nal part of the manual).

9

DIAGNOSTICS

Some devices are display messages to identify their status and faults.

9.1 - Control unit signals

The leds on the control unit issue signals to indicate their normal/faulty operation.

Table 13 lists the signals:

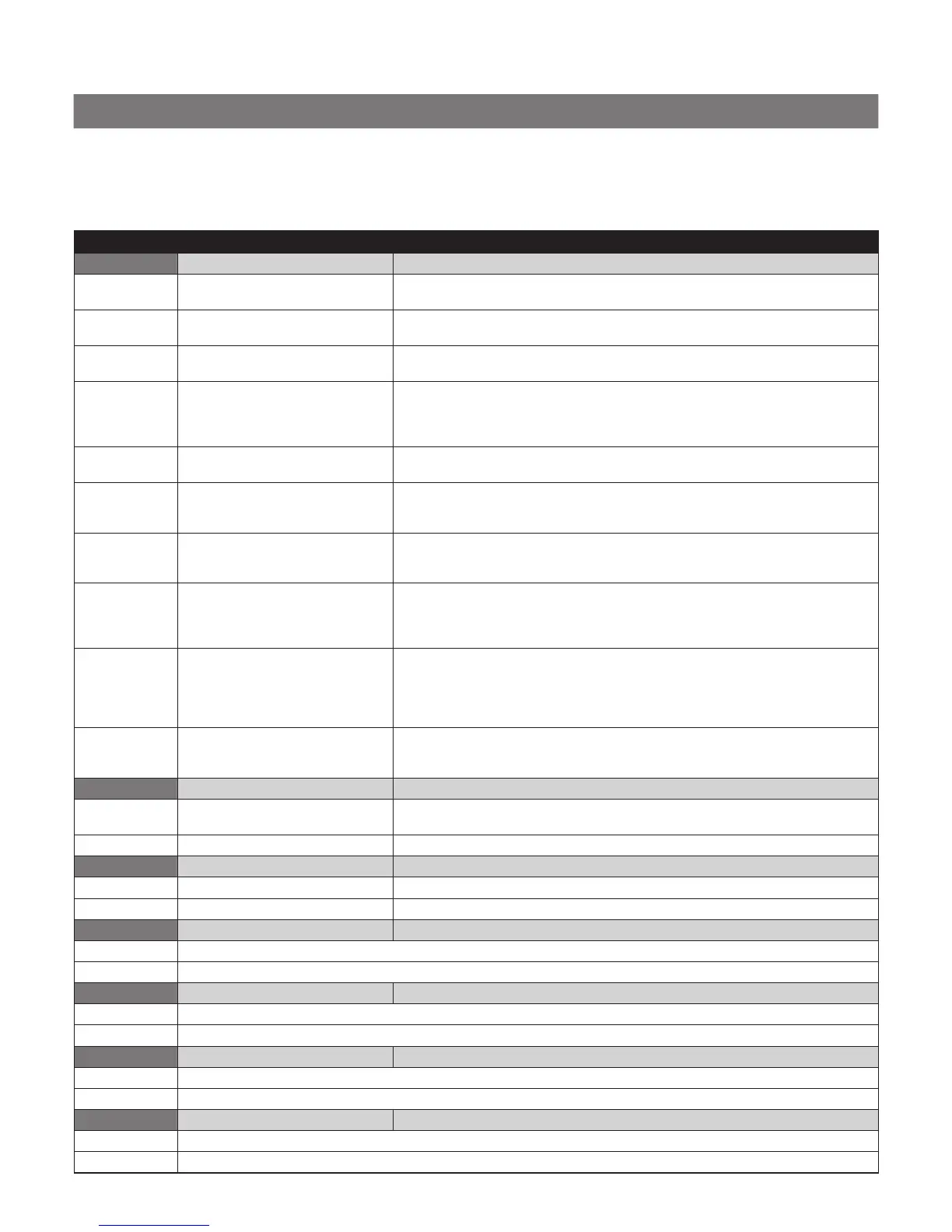

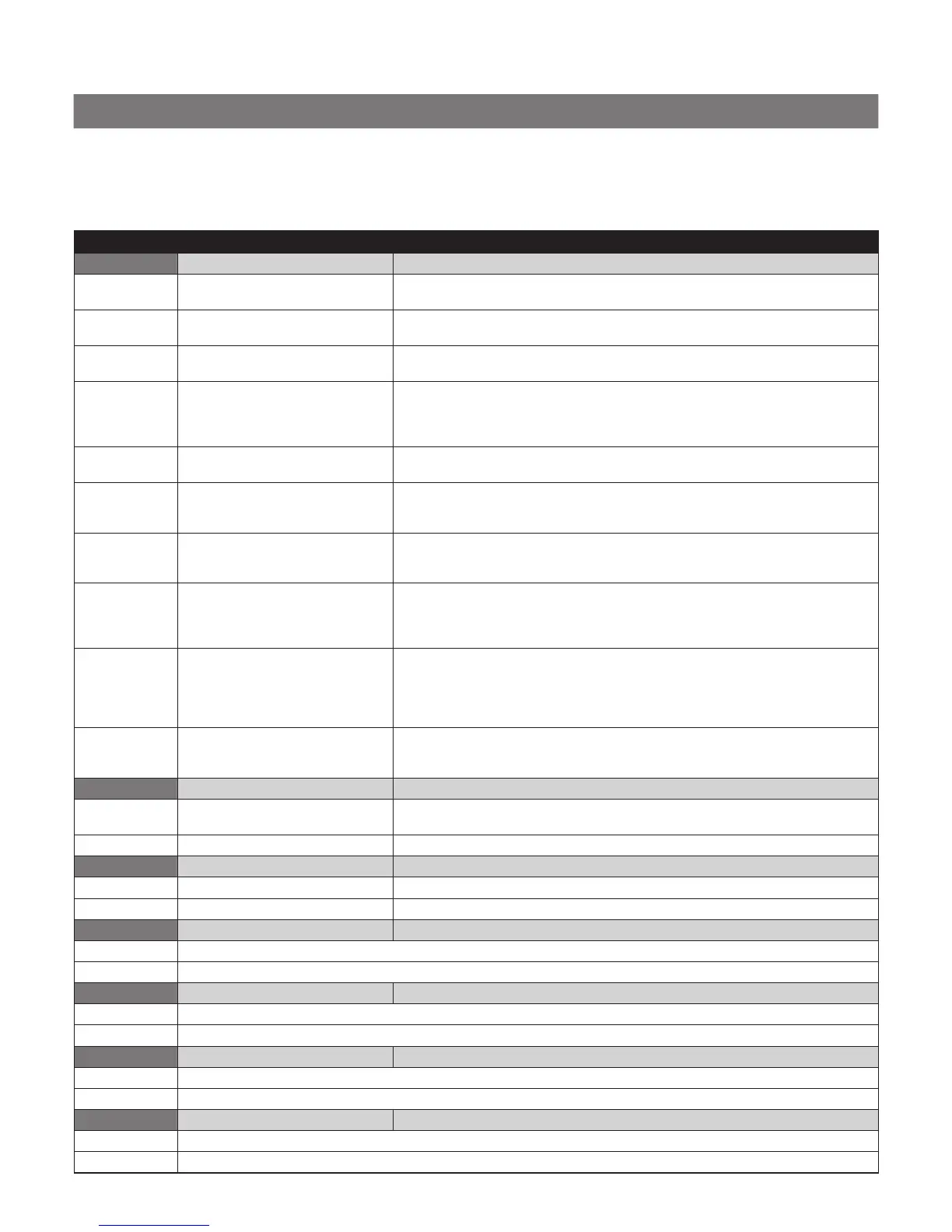

Table 13

OK LED Cause Solution

Red and green

leds OFF

Serious Check if the power is on; check fuses have not been tripped: if that is the case, check

the cause of the fault and replace with others of the same value.

Red or green

led ON

Serious

malfunction

Try and switch the control unit off for a few seconds; if the situation does not

change, there is a fault and the electronic board must be replaced.

1 green ash a

second

All OK Normal operation of the control unit.

1 red ash

1 sec. pause

1 red ash

the installation of the devices was

not successful or the conguration

of the 1-2 dip switches was changed

without re-learning the devices

Check the correct connection of the alt and photocell inputs (see gure 7 and

paragraphs 8.1.1 and 8.1.2) or if the conguration of micro switches 1-2 has been

changed, perform the device learning procedure (paragraph 5.2)

2 quick green

ashes

There has been a change

in the input status

This is normal when there is a change in one of the inputs: SbS,

STOP, triggering of photocells or the radio transmitter is used.

2 red ashes

1 sec. pause

2 red ashes

Triggering of a photocell At the beginning of the manoeuvre, one or more photocells are preventing movement:

check to see if there are any obstacles.

During the closing movement it is normal if an obstacle is really present.

4 red ashes

1 sec. pause

4 red ashes

Activation of the STOP input At the start of the manoeuvre or during the movement, the STOP input has been

triggered:

check the cause.

5 red ashes

1 sec. pause

5 red ashes

Internal parameter memorisation

error

Wait at least 30 seconds during which the control unit tries to reset. If the situation

does not change,

it is necessary to delete the memory and carry out the storing procedure again

7 red ashes

1 sec. pause

7 red ashes

- Error in the internal circuits.

- conguration of programming

switches 1 and 2 changed

Disconnect all the power circuits for a few seconds, then try again and send

a command; if the situation does not change there may be a serious fault on the

board or on the motor wiring: check and replace as required.

If the conguration of switches 1 and 2 has been modied, repeat the device learning

procedure or reset the previous conguration

8 red ashes

1 sec. pause

8 red ashes

Command already present. Another command is already present. Remove the command to be able to send

more.

PHOTO led Cause Solution

Off Photocell input activated At the start of the manoeuvre, one or more photocells are preventing movement;

check to see if there are any obstacles, also check the NC connection for faults.

On All OK The photocell is aligned and the movement is permitted

STOP led Cause Solution

Off Activation of the STOP input Check the devices connected to the STOP input

On All OK STOP Input active

SbS led Cause Solution

Off Step-by-step command not present

On Step-by-step command present

FCA led Cause Solution

Off FCA limit switch input triggered

On FCA limit switch input closed

FCC led Cause Solution

Off FCC limit switch input triggered

On FCC limit switch input closed

RADIO led R Cause Solution

Off During normal operation, it shows a radio code that is not in the memory has been received.

On Radio transmitter programming or deletion in progress

Loading...

Loading...