Installation

A1-69

E 2000 Nordson Corporation

All rights reserved

41-3000V

Issued 5/00

A3EN-04-[3V-A-AAXP]-12

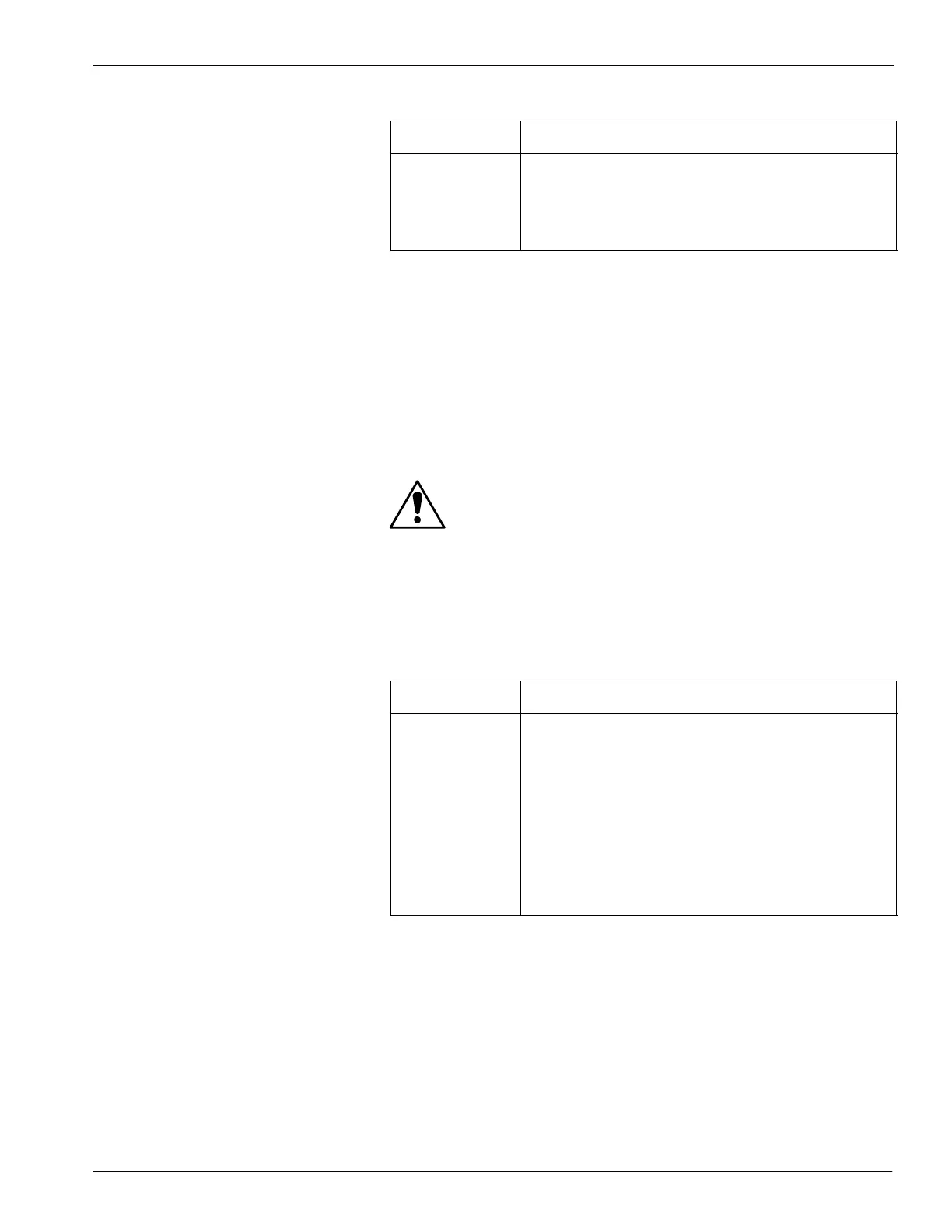

Table A 1-20 Filter Cleaning Procedures

Filter Type

Cleaning Procedure

Standard Refer to Cleaning a Standard Manifold Filter in the

Maintenance section of this manual.

Reverse-flush Refer to Cleaning a Reverse-Flush Manifold Filter in

the Maintenance section of this manual.

5. Prepare each gun in your system for operation as follows:

S Air-operated guns: increase the operating air pressure to

240 kPa (35 psi).

S Electric guns: turn on the gun driver.

S Hand-operated guns: unlock the trigger.

WARNING: Trapped air may still be in the hoses and guns.

Shield the area and operator from splashing adhesive.

6. Trigger the guns, keeping them open so that no pressure builds up.

NOTE: You may need to adjust the gun air pressure depending on

the viscosity of the adhesive and the gun response.

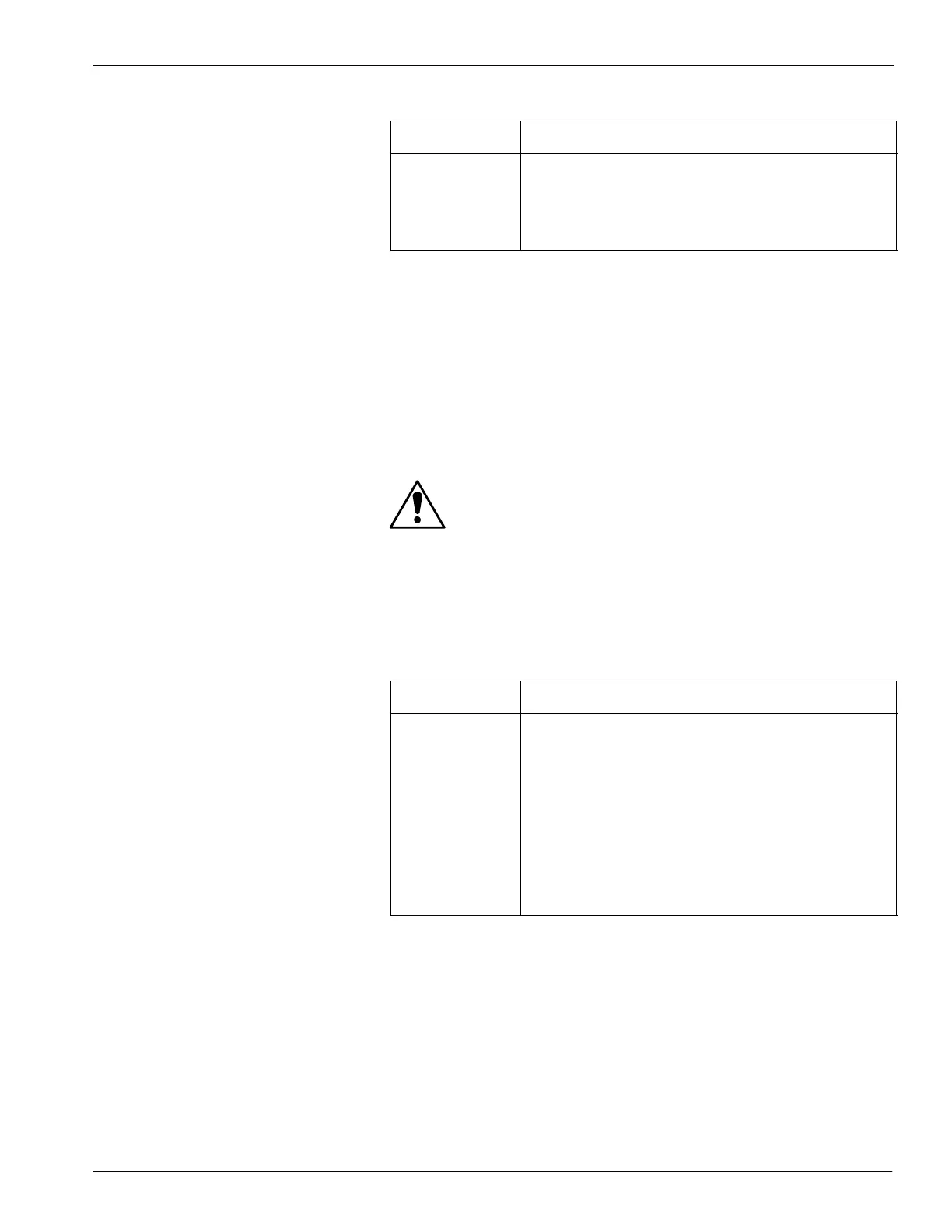

7. Flush the system by using one of the following methods, depending

upon the type of pump your unit has (see Figure A 3-4).

Pump Type

Flushing Method

Piston pump If the PUMP light is not on, press the PUMP key.

Gradually increase air pressure to the pump by

turning the air pressure regulator clockwise. Allow

adhesive to flow out of the guns until all trapped air,

cleaning solution, and impurities are flushed out of

the system. If the pump slows noticeably or stops,

increase pump air pressure slightly.

Gear pump with

AC motor drive

Press the PUMP key and allow adhesive to flow out

of the guns until all trapped air, cleaning solution,

and impurities are flushed out of the system.

8. Stop triggering the guns.

Loading...

Loading...