Regular Payload Series-Hardware Installation Manual TM5 Series Hardware Version: 3.2 34

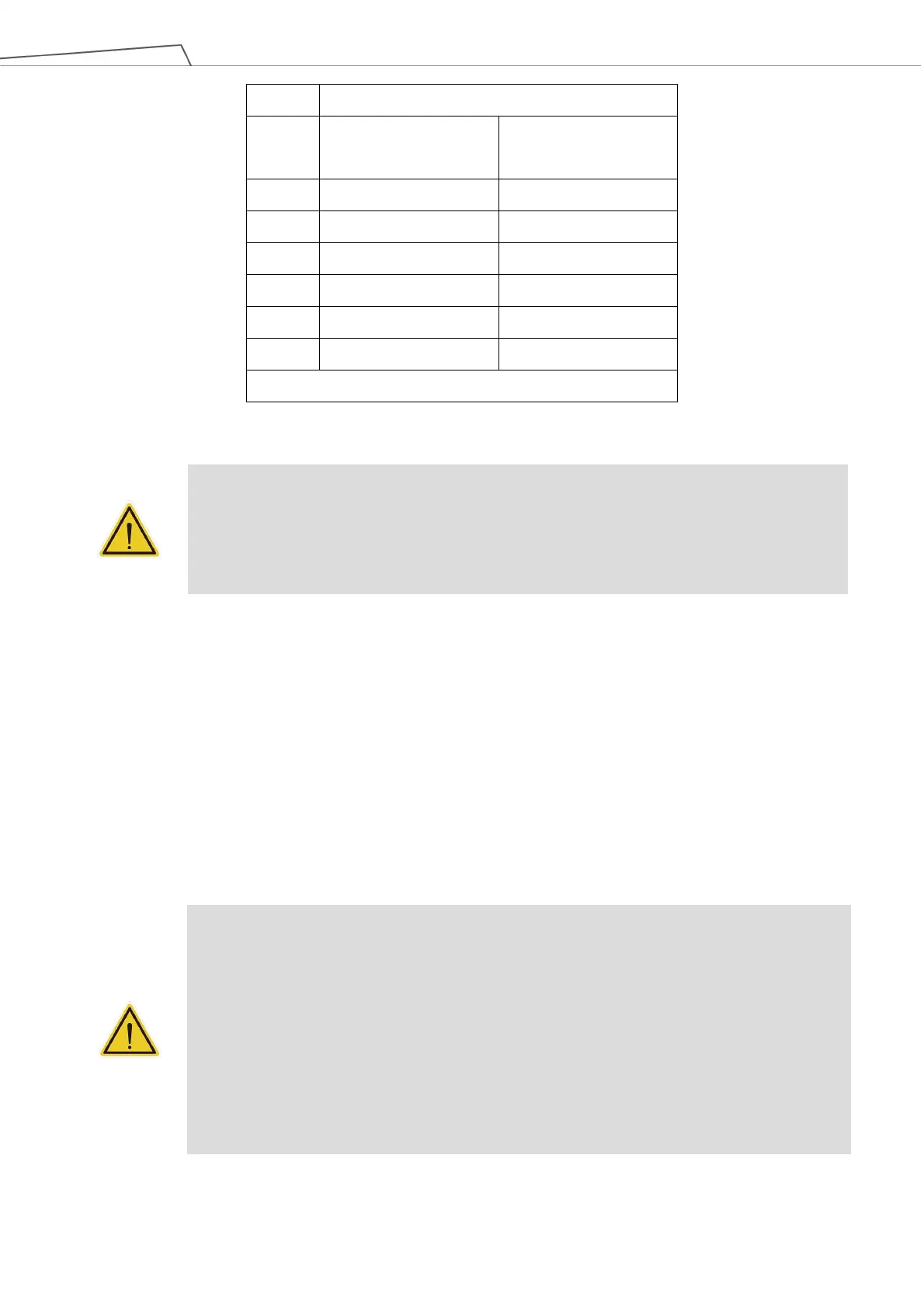

Model TM5-700 & TM5-900 Series

Item Rated torque Limit for repeated peak

torque

J1 118 157

J2 118 157

J3 118 157

J4 23 43

J5 23 43

J6 23 43

Unit: Nm

Table 4: Rated Torque and Limit for Repeated Peak Torque of Regular Payload Robot Series

WARNING:

Use the total weight of the end-effector and the payload to stay within the payload rating of the

robot. Ensure that the system never exceeds that maximum payload.

You should perform a full risk assessment that includes the end-effector and payload samples,

to ensure the safety of the entire system.

4.2.1.6 Robot Arm Installation

The robot can be secured to another surface with the use of (4) M10 screws and washers. The mounting

pattern is shown below. The recommended tightening torque is 40 Nm.

Optional - Two openings for 6 mm position pins are provided for more secure position mounting.

Ensure the strength of the mounting surface and its surround area before installations for upside down

mounting and side mounting such as on the ceiling or the wall. Wherever the installation takes place, the

robot setting remains equivalent.

DANGER:

1.

The TM Robot must be securely and tightly screwed down before use. The strength of the

mounting surface must be sufficient.

When operating at high speed, the robot can generate up to 350

N reaction force to the

mounting surface and screws. In order to avoid decreased performance caused by robot

slip or vibration, the recommended mounting surface should be a steel plate at least 20

mm thick, its flatness should be 0.1

mm or less, its surface roughness should be Rz25 or

less. The recommended screw should be M10 x L30 mm, at least 8.8 strength.

2.

Do not immerse TM Robot in water. Installation in water or a humid environment will

permanently damage the robot.

Loading...

Loading...