NHC,

NHCV

Installation Guidelines

VENTILATION

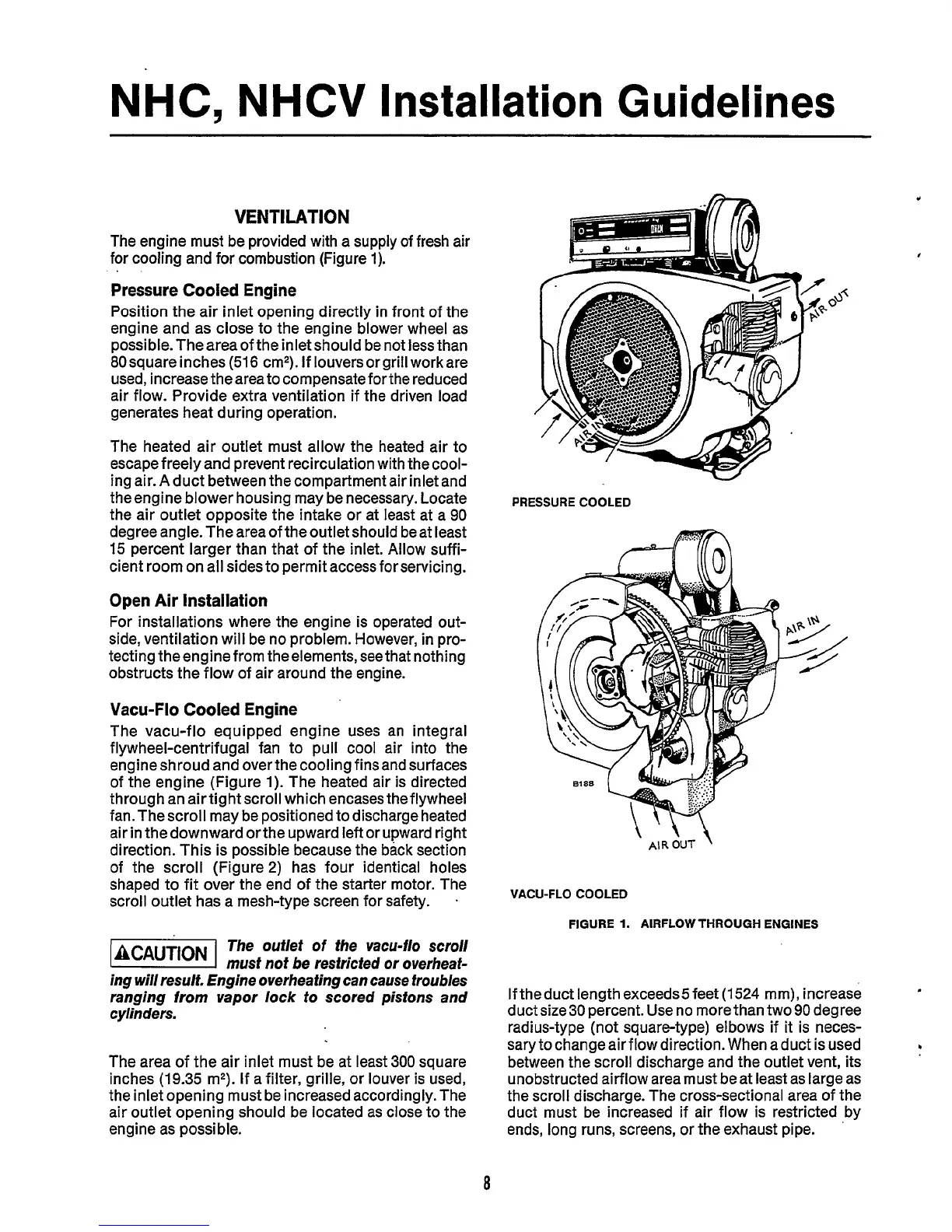

The engine must be provided with a supply of fresh air

for cooling and for combustion (Figure

1).

Pressure Cooled Engine

Position the air inlet opening directly in front of the

engine and as close to the engine blower wheel as

possible.Theareaoftheinletshould

be not lessthan

80

square inches

(516

cm'). If louvers or grill work are

used, increase thearea to compensate forthe reduced

air flow. Provide extra ventilation if the driven load

generates heat during operation.

The heated air outlet must allow the heated air to

escape freely and prevent recirculation with thecool-

ing air. A duct between the compartment air inlet and

theengine blower housing may be necessary. Locate

the air outlet opposite the intake or at least at a

90

degree angle. The area of the outlet should be at least

15

percent larger than that of the inlet. Allow suffi-

cient room on all sides to permit access forservicing.

Open Air Installation

For installations where the engine is operated out-

side, ventilation will be no problem. However, in pro-

tecting theengine from theelements, seethat nothing

obstructs the flow of air around the engine.

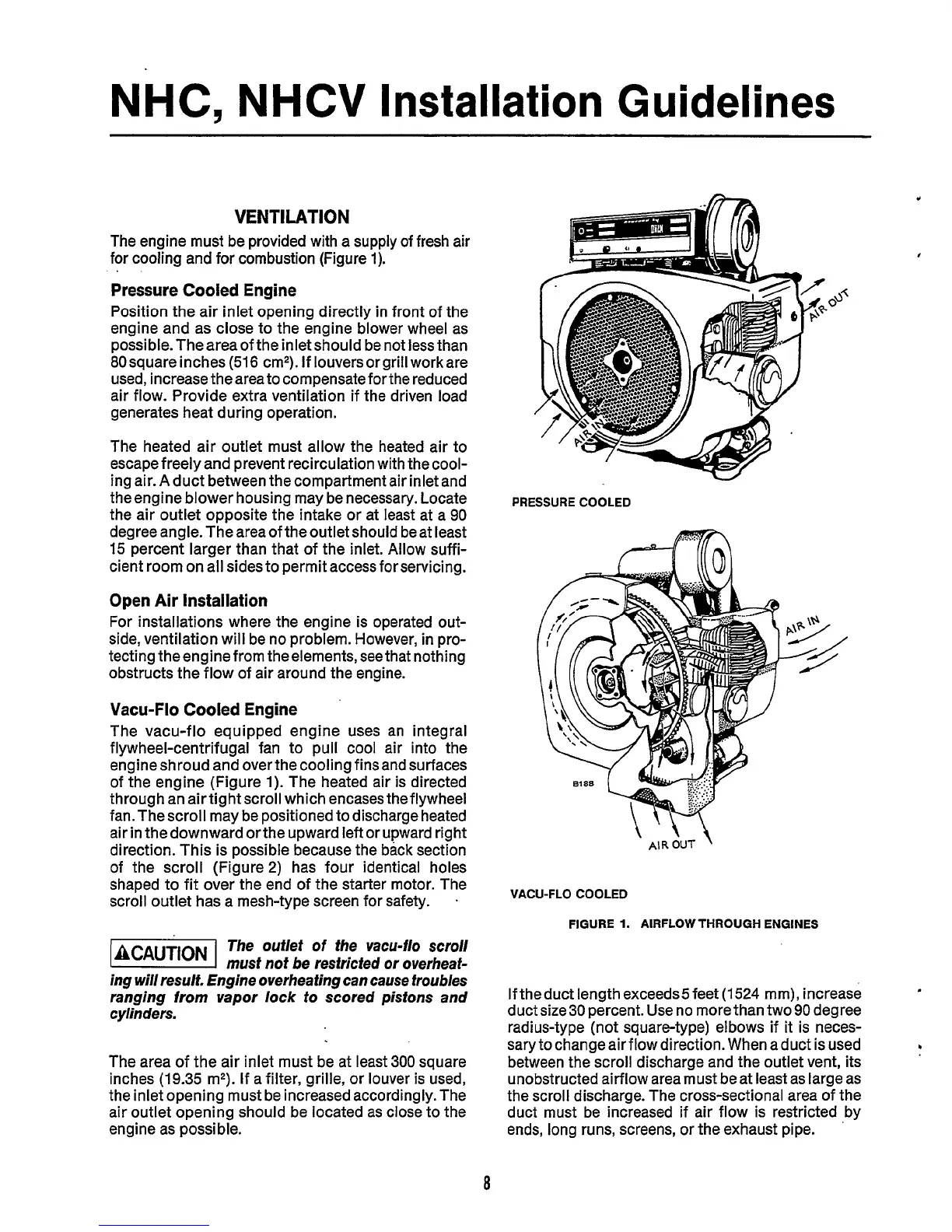

Vacu-Flo

Cooled Engine

The vacu-flo equipped engine uses an integral

flywheel-centrifugal fan to pull cool air into the

engine shroud and over the cooling finsand surfaces

of the engine (Figure

1).

The heated air is directed

through an airtight scroll which encasestheflywheel

fan. The scroll may be positioned to discharge heated

air in the downward orthe upward left or upward right

direction. This is possible because the back section

of the scroll (Figure2) has four identical holes

shaped to fit over the end of the starter motor. The

scroll outlet has a mesh-type screen for safety.

.

The ouflef

of

the vacu-flo scroll

@!@%I

musf nof be resfricfed or overheaf-

ing will result. Engine overhea fing can cause troubles

ranging

from

vapor lock

to

scored pistons and

cylinders.

The area of the air inlet must be at least

300

square

inches

(19.35

m2).

If

a filter, grille, or louver

is

used,

the inlet opening must be increased accordingly. The

air outlet opening should be located as close to the

engine

as

possible.

PRESSURE COOLED

m

PRESSURE COOLED

m

VACU-FLO

COOLED

FIGURE

1.

AIRFLOW

THROUGH ENGINES

Iftheduct length exceeds5feet

(1524

mm), increase

duct size

30

percent. Use no more than two

90

degree

radius-type (not square-type) elbows if

it

is neces-

sary to change air flow direction. When aduct is used

between the scroll discharge and

the

outlet vent, its

unobstructed airflow area must be at least as large as

the scroll discharge. The cross-sectional area of the

duct must be increased if air flow is restricted by

ends, long runs, screens, or the exhaust pipe.

b

8

Loading...

Loading...