Electric Fuel

Pump

All engines used on Onan

N

series generator sets are

equipped with an electric fuel pump. The pump is

manufactured by Facet (a division of Bendix Corpo-

ration) and carries a Facet nameplate. An internal fuel

shutoff valve is a standard feature on this pump.

Older versions

of

this pump carry the Bendix name-

plate and do not have an internal fuel shutoff valve.

Service proceduresforthe Facet or Bendix pump are

the same.

Do

not substitute automotive type

laWAR”Gl

electric fuel pumps for standard

Onan supplied electric pumps. The

output

pressure

is much higher and can cause carburetor flooding

or

fuel

leakage, creafing a fire hazard.

Pump

Tesf:Test the fuel pump by checking the pump

outlet pressure. Use the following procedure.

1.

2.

3.

Remove the fuel line from the pump outlet and

install a pressure gauge.

Press the START switch and hold

it

for several

seconds until pressure reading is constant.

Pressure reading should be 2-1/2 to

3-1/4

psi

(17.2 to 22.4 kPa). If the retension is good, the

pressure should stay constant or drop

off

very

slowly.

A low pressure reading with little or no pressure drop

indicates a weak or broken diaphragm or diaphragm

spring, worn linkage,or leaky check valves. If pressure

is above maximum, the pump diaphragm is too tight

or the diaphragm (or plunger) return spring is too

strong. Any of the above conditions are cause for

repair or replacement of the pump.

Fuel Pump Repair:

Service of the Facet pump

is

limited to the bottom cover, filter, plunger tube, and

plunger assembly. All parts

of

the electric system are

hermetically sealed in a gas atmosphere and are not

serviceable. If electrical failure occurs, replace the

Pump.

Do

not tamper with the seal at the

@%@@

cenfer

of

fhe mounting bracket

on

the side of the pump as

if

retains the dry gas which

surrounds fhe electrical system. Electrical system

components are nof serviceable.

Use the following procedure for servicing the pump:

1.

Using a5/8-inch wrench, loosen, the pump cover,

then remove by hand.

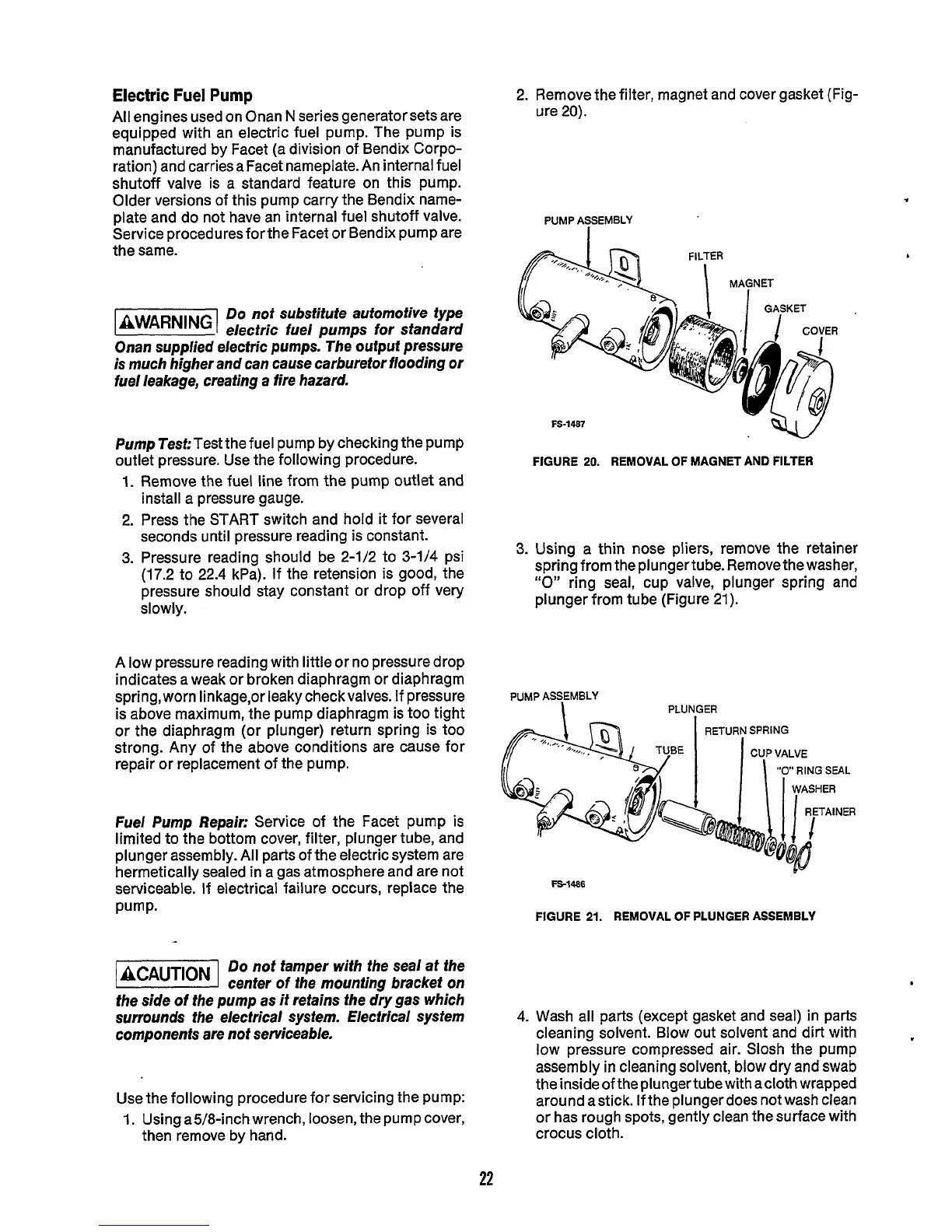

2. Remove the filter, magnet and cover gasket (Fig-

ure 20).

PUMP ASSEMBLY

I

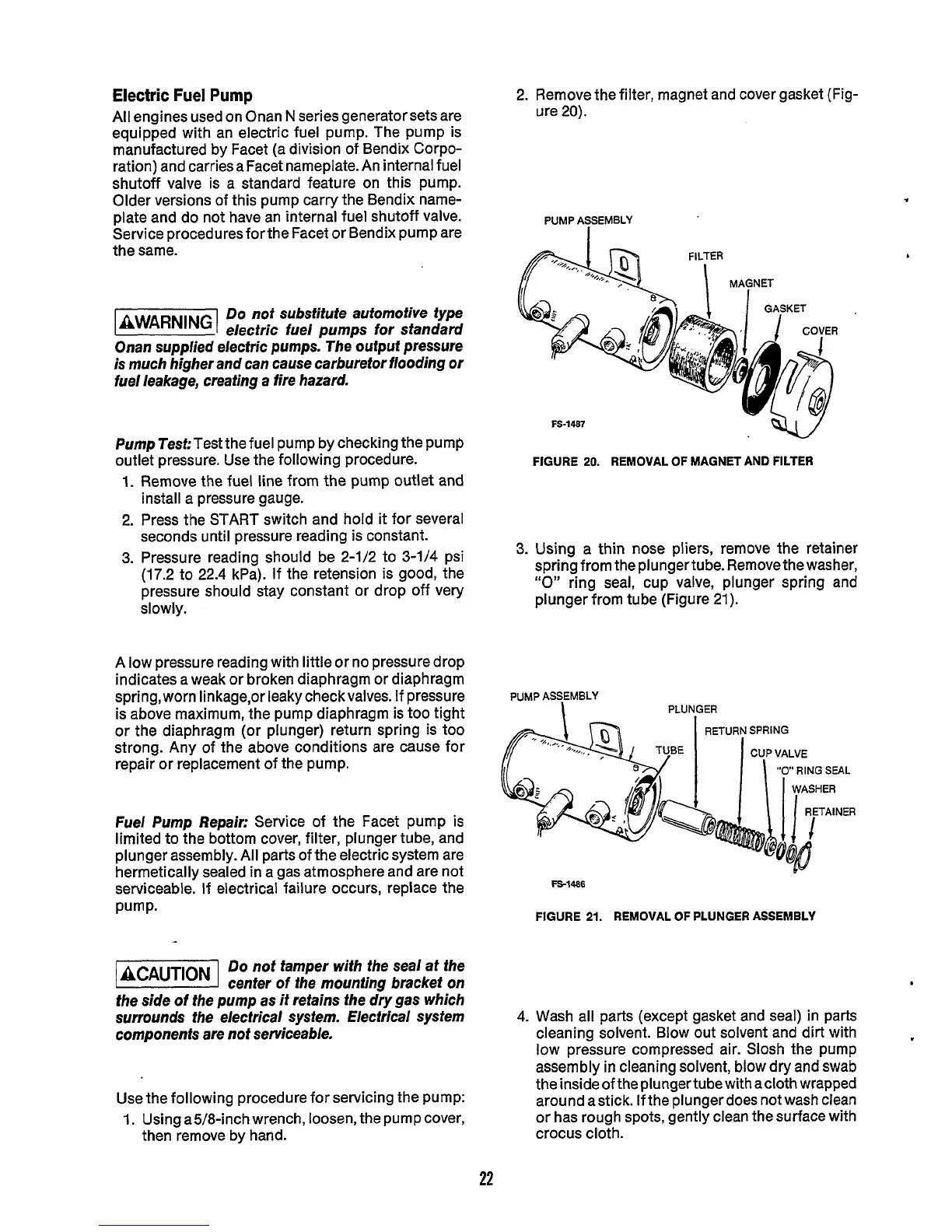

3.

FS-1487

FIGURE

20.

REMOVAL

OF

MAGNET AND FILTER

Using a thin

nose

pliers, remove the retainer

spring from the plungertube. Remove the washer,

“0”

ring seal, cup valve, plunger spring and

plunger from tube (Figure

21).

PUMP ASSEMBLY

PLU

N,GER

FS-1486

FIGURE

21.

REMOVAL

OF

PLUNGER ASSEMBLY

4.

22

Wash all parts (except gasket and seal) in parts

cleaning solvent. Blow out solvent and dirt with

low pressure compressed air. Slosh the pump

assembly

in

cleaning solvent, blow dry and

swab

the inside of the plunger tube with acloth wrapped

around astick. lfthe plungerdoes notwash clean

or has rough spots, gently clean the surface with

crocus cloth.

Loading...

Loading...