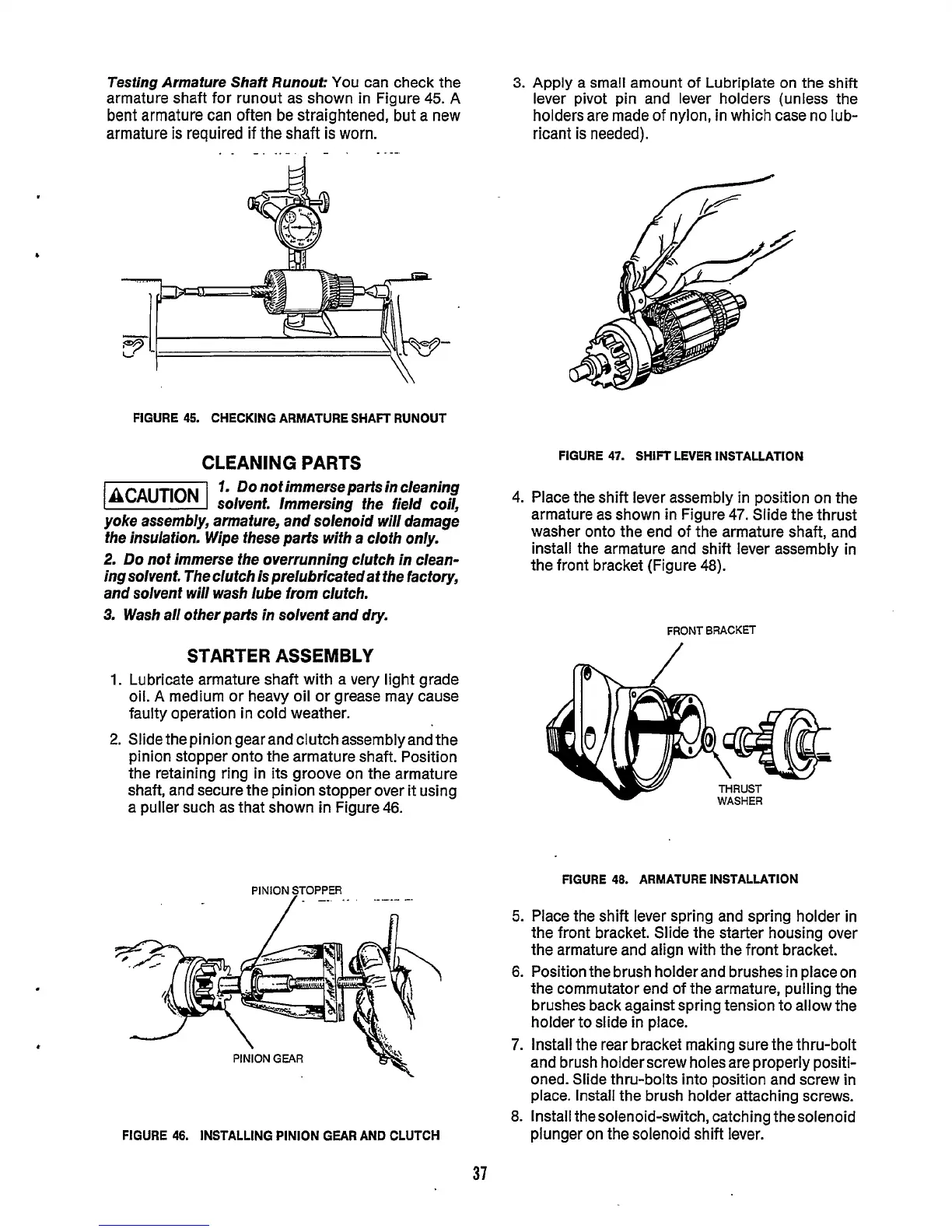

Testing Armature

Shaff

Runout:

You can check the

armature shaft for runout as shown in Figure

45.

A

bent armature can often be straightened, but a new

armature

is

required if the shaft

is

worn.

FIGURE

45.

CHECKING ARMATURE SHAFT RUNOUT

CLEANING PARTS

1.

Do

not immerse parts in cleaning

(BCAUTIONI

solvent. Immersing the field coil,

yoke assembly, armature, and solenoid will damage

fhe insulafion. Wipe these parts with a cloth only.

2.

Do

nof

immerse fhe overrunning clutch in clean-

ing solvent- The clutch

is

prelubricafedat the factory,

and solvent will wash lube from clutch.

3.

Wash all other parts in solvent and dry.

STARTER ASSEMBLY

1.

Lubricate armature shaft with a very light grade

oil.

A

medium or heavy oil or grease may cause

faulty operation in cold weather.

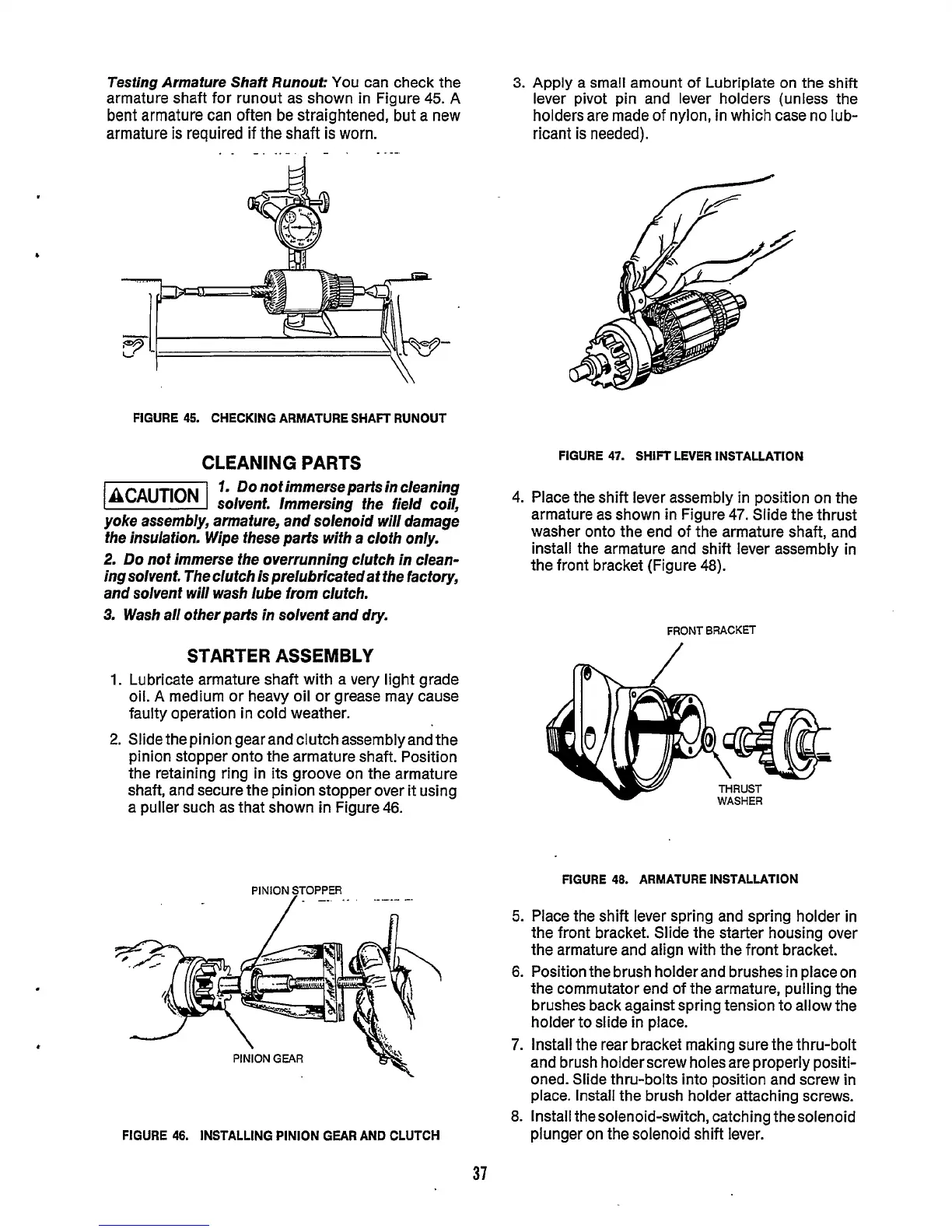

2.

Slide the pinion gear and clutch assembly and the

pinion stopper onto the armature shaft. Position

the retaining ring in its groove on the armature

shaft, and secure the pinion stopper over it using

a puller such as that shown in Figure 46.

3.

Apply a small amount of Lubriplate on the shift

lever pivot pin and lever holders (unless the

holders are made

of

nylon, in which case no lub-

ricant

is

needed).

FIGURE

47.

SHIFT LEVER INSTALLATION

4. Place the shift lever assembly in position on the

armature as shown in Figure 47. Slide the thrust

washer onto the end of the armature shaft, and

install the armature and shift lever assembly in

the front bracket (Figure 48).

FRONT

BRACKET

I

FIGURE

46.

ARMATURE INSTALLATION

PINION

STOPPER

..

,

-.

5.

Place the shift lever spring and spring holder in

the front bracket. Slide the starter housing over

the armature and align with the front bracket.

6.

Position the brush holder and brushes in place on

the commutator end of the armature, pulling the

brushes back against spring tension to allow the

holder to slide in place.

7.

Install the rear bracket making sure the thru-bolt

and brush holder screw holes are properly positi-

oned. Slide thru-bolts into position and screw

in

place. Install the brush holder attaching screws.

8. Install thesolenoid-switch, catching the solenoid

plunger on the solenoid shift lever.

FIGURE

46.

INSTALLING PINION GEAR

AND

CLUTCH

37

Loading...

Loading...