INSPECTION

AFTER

OVERHAUL

For no-load test, the starting motor is wired as

shown in Figure

49

and run. The value of the

meter reading at this condition should be as

follows:

Begin Spec

B

Voltage 10.5 11.5

RPM

5000

3700

Max. Current

Draw (Amp)

53

60

Spec

A

Only

1.

AMMETER

SWITCH

INDICATOR

FIGURE

49.

WIRING STARTER FOR NO-LOAD TESTS

The conductor for this test should be large enough in

diameter and as short as possible.

If

anything

is

wrong in

the above test, inspect the following items:

Annealed brush springs

Improperly sealed brushes

Insufficient armature endplay

Shorted, open, or grounded armature

Grounded or open field coil

Poor electrical connection

Dirty commutator

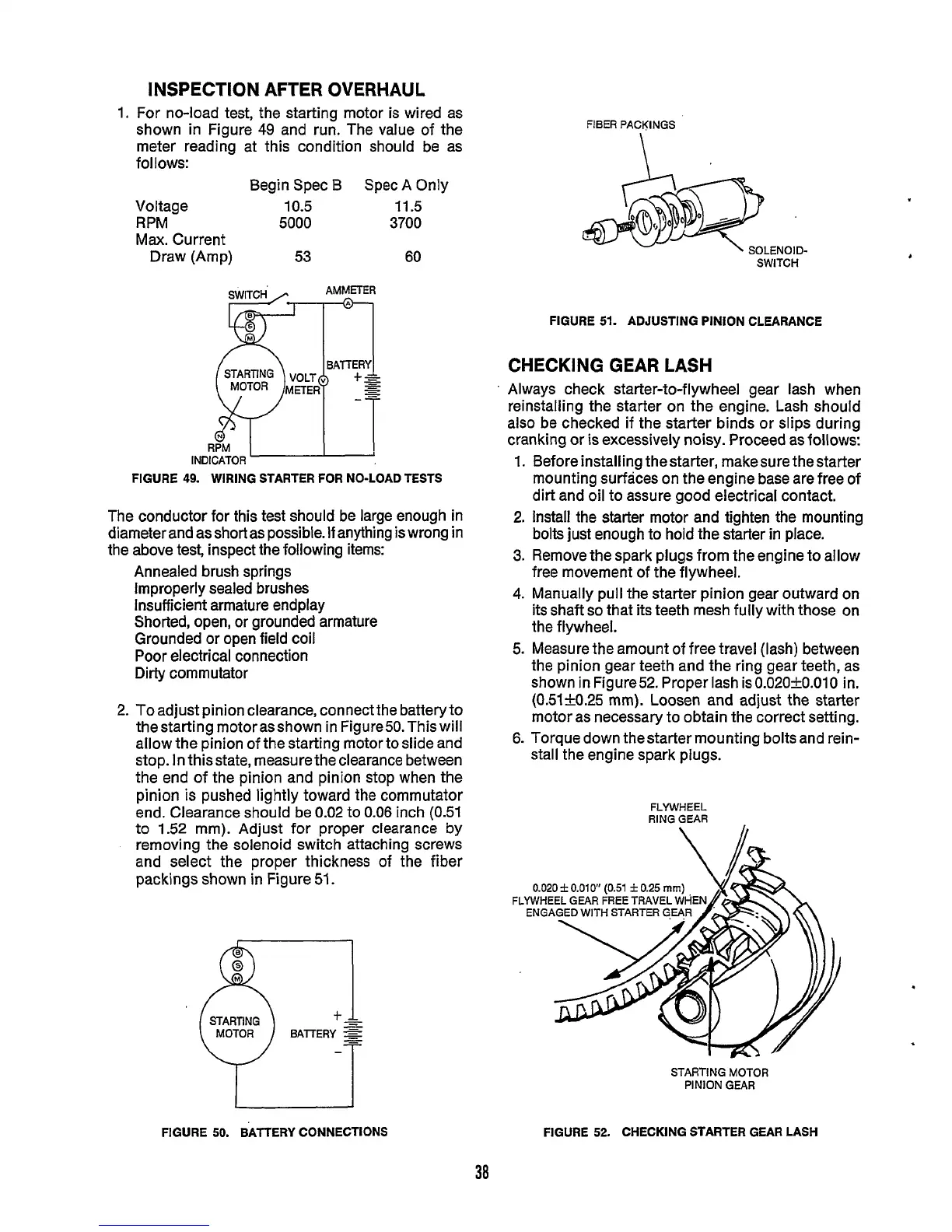

2.

To

adjust pinion clearance, connect the battery to

thestarting motorasshown in Figure50.This will

allow the pinion of the starting motor to slide and

stop. In this state, measure the clearance between

the end of the pinion and pinion stop when the

pinion

is

pushed lightly toward the commutator

end. Clearance should be

0.02

to

0.06

inch (0.51

to 1.52 mm). Adjust for proper clearance by

removing the solenoid switch attaching screws

and select the proper thickness of the fiber

packings shown

in

Figure

51.

FIBER

PACKINGS

FIGURE

51.

ADJUSTING PINION CLEARANCE

CHECKING

GEAR

LASH

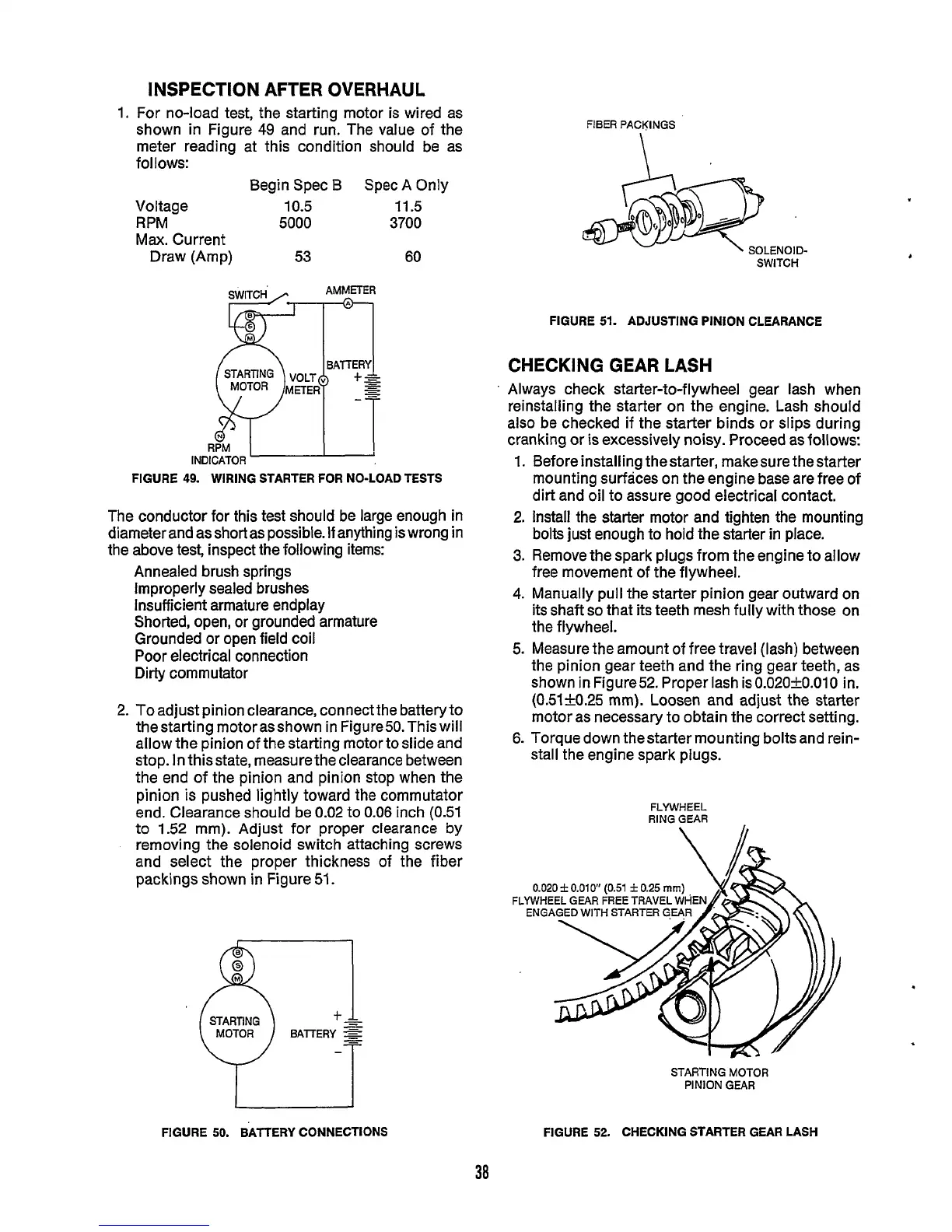

Always check starter-to-flywheel gear lash when

reinstalling the starter on the engine. Lash should

also be checked if the starter binds or slips during

cranking or

is

excessively noisy. Proceed as follows:

1.

2.

3.

4.

5.

Before installing thestarter, make sure

the

starter

mounting surfaces on the engine base are free of

dirt and oil to assure good electrical contact.

Install the starter motor and tighten the mounting

bolts just enough to hold the starter in place.

Remove the spark plugs from the engine to allow

free movement of the flywheel.

Manually pull the starter pinion gear outward on

its shaft

so

that

its

teeth mesh fully with those on

the flywheel.

Measure the amount of free travel (lash) between

the pinion gear teeth and the ring gear teeth, as

shown in Figure52. Proper lash isO.O20+0.010 in.

(0.51+_0.25 mm). Loosen and adjust the starter

motor as necessary to obtain the correct setting.

6.

Torque down thestarter mounting bolts and rein-

stall the engine spark plugs.

FLYWHEEL

RING

GEAR

0.020

f

0.010''

(0.51

f

0.25

mm)

FLYWHEEL

GEAR FREE

TRAVEL

WHE

ENGAGED WITH

STARTER

G.EqR

STARTING

MOTOR

PINION

GEAR

FIGURE

50.

BATTERY

CONNECTIONS

38

FIGURE

52.

CHECKING STARTER GEAR LASH

Loading...

Loading...