.

FUEL

PUMPS

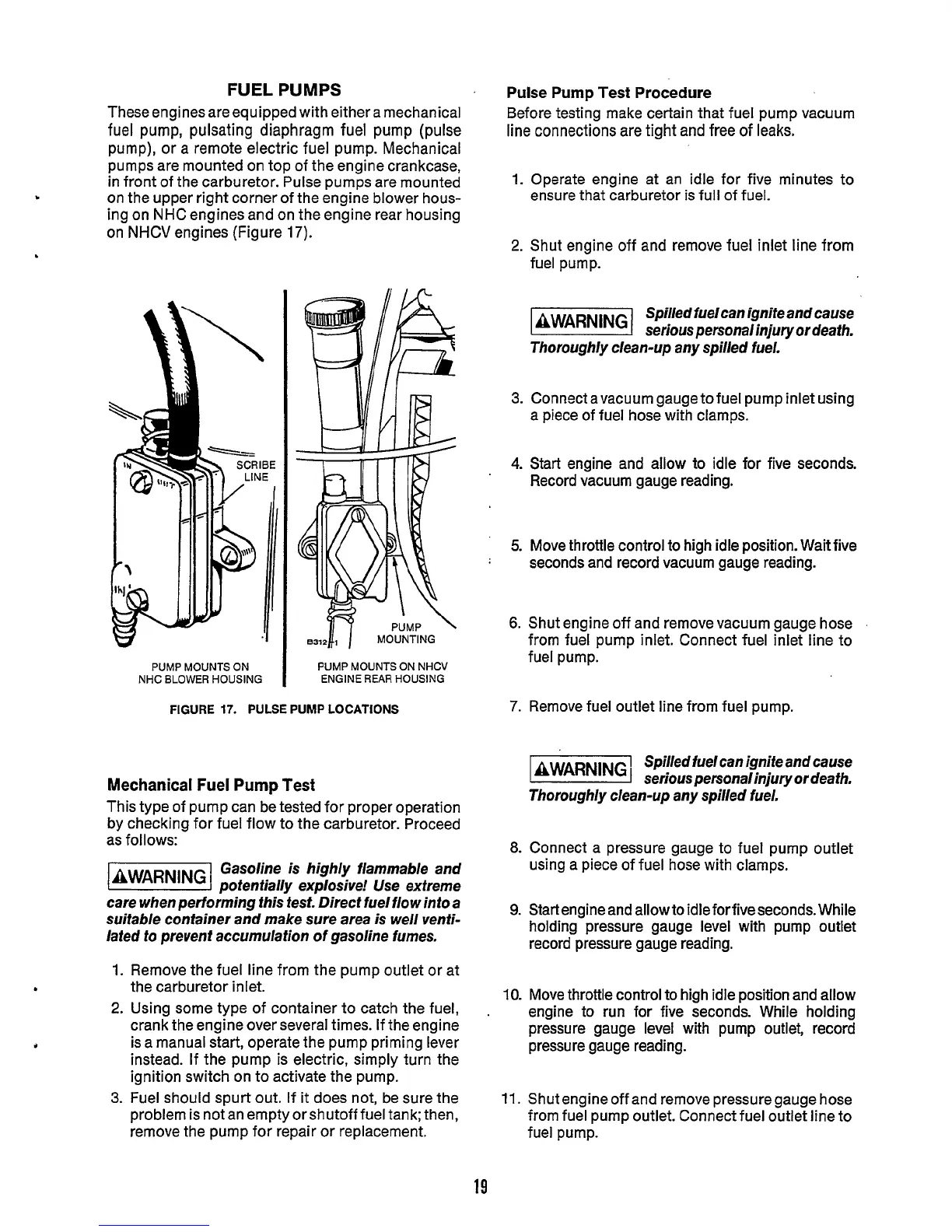

These engines are equipped with either a mechanical

fuel pump, pulsating diaphragm fuel pump (pulse

pump), or a remote electric fuel pump. Mechanical

pumps are mounted on top of the engine crankcase,

in front of the carburetor. Pulse pumps are mounted

on the upper right corner of the engine blower hous-

ing on

NHC

engines and on the engine rear housing

on

NHCV

engines (Figure

17).

'

Pulse Pump Test Procedure

Before testing make certain that fuel pump vacuum

line connections are tight and free

of

leaks.

1.

Operate engine at an idle for five minutes to

ensure that carburetor is full of fuel.

2.

Shut engine off and remove fuel inlet line from

fuel pump.

PUMP MOUNTS ON

NHC BLOWER HOUSING

PUMP MOUNTS ON NHCV

ENGINE REAR HOUSING

FIGURE

17.

PULSE

PUMP

LOCATIONS

Mechanical Fuel

Pump

Test

This type of pump can be tested for proper operation

by checking for fuel flow to the carburetor. Proceed

as follows:

Gasoline is highly flammable and

laWARNlNGl

potentially explosive! Use extreme

care when performing this test. Direct fuel flow into a

suitable container and make sure area is well venti-

lated to prevenf accumulation of gasoline fumes.

1.

Remove the fuel line from the pump outlet or at

the carburetor inlet.

2.

Using some type of container to catch the fuel,

crank the engine over several times. If the engine

is a manual start, operate the pump priming lever

instead. If the pump is electric, simply turn the

ignition switch on to activate the pump.

3.

Fuel should spurt out. If

it

does not, be sure the

problem is not an empty orshutoff fuel tank; then,

remove the pump for repair or replacement.

Spilled fuelcan ignite and cause

k!@@%!l

serious personalinjury or death.

Thoroughly clean-up any spilled fuel.

3.

Connect avacuum gauge tofuel pump inlet using

a piece of fuel hose with clamps.

4.

Start engine and allow to idle for five seconds.

Record vacuum gauge reading.

5.

Move throttle control to high idle position. Wait five

;

seconds and record vacuum gauge reading.

6.

Shut engine

off

and remove vacuum gauge hose

from fuel pump inlet. Connect fuel inlet line to

fuel pump.

7.

Remove fuel outlet line from fuel pump.

Spilled fuel can ignite and cause

serious personalinjury or death.

Thoroughly clean-up any spilled fuel.

8.

Connect a pressure gauge to fuel pump outlet

using a piece of fuel hose with clamps.

9.

Start engine and allow to idle forfive seconds. While

holding pressure gauge level with pump outlet

record pressure gauge reading.

10.

Move throttle control

to

high idle position and allow

engine to run for five seconds. While holding

pressure gauge level with pump outlet, record

pressure gauge reading.

.

11.

Shut engine off and remove pressure gauge hose

from fuel pump outlet. Connect fuel outlet line

to

fuel pump.

19

Loading...

Loading...