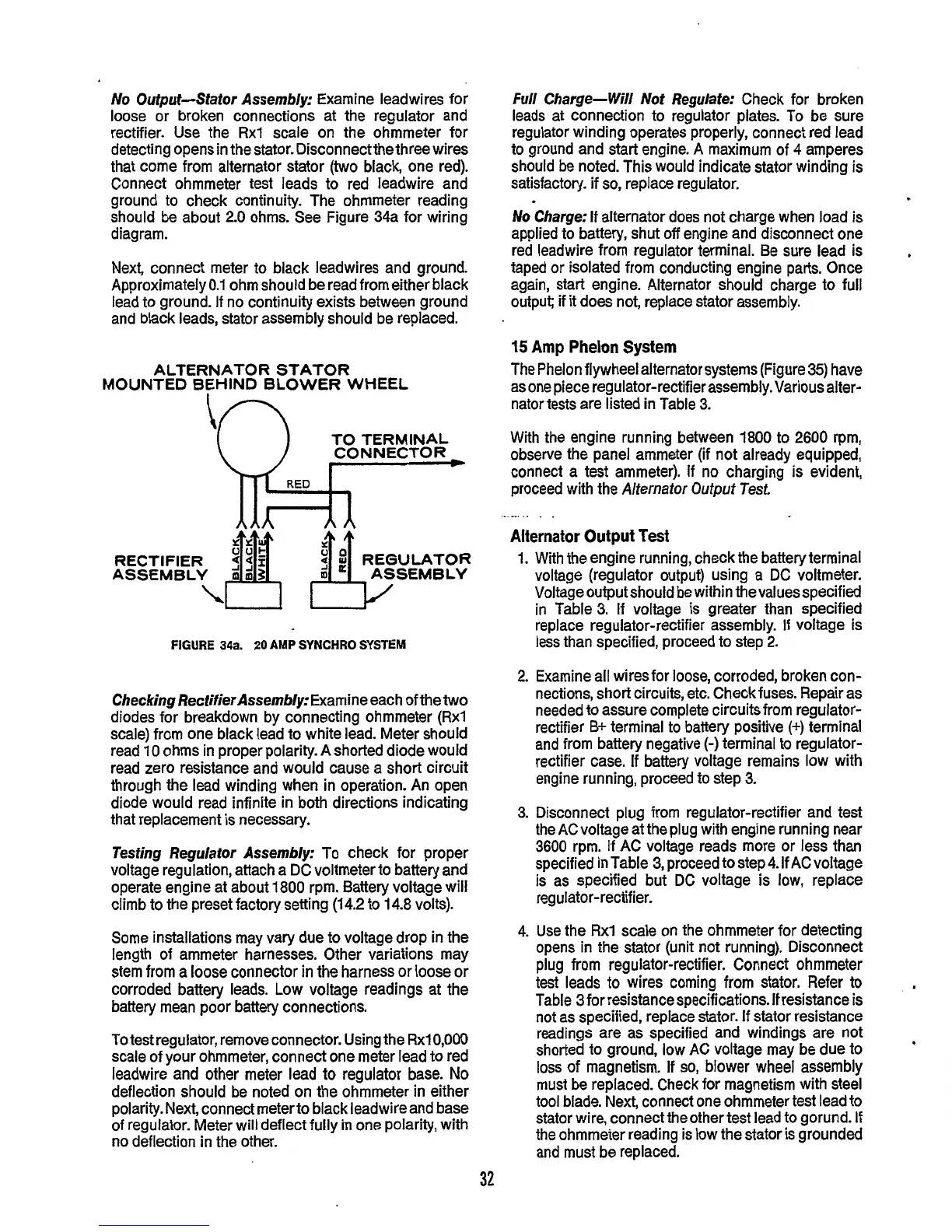

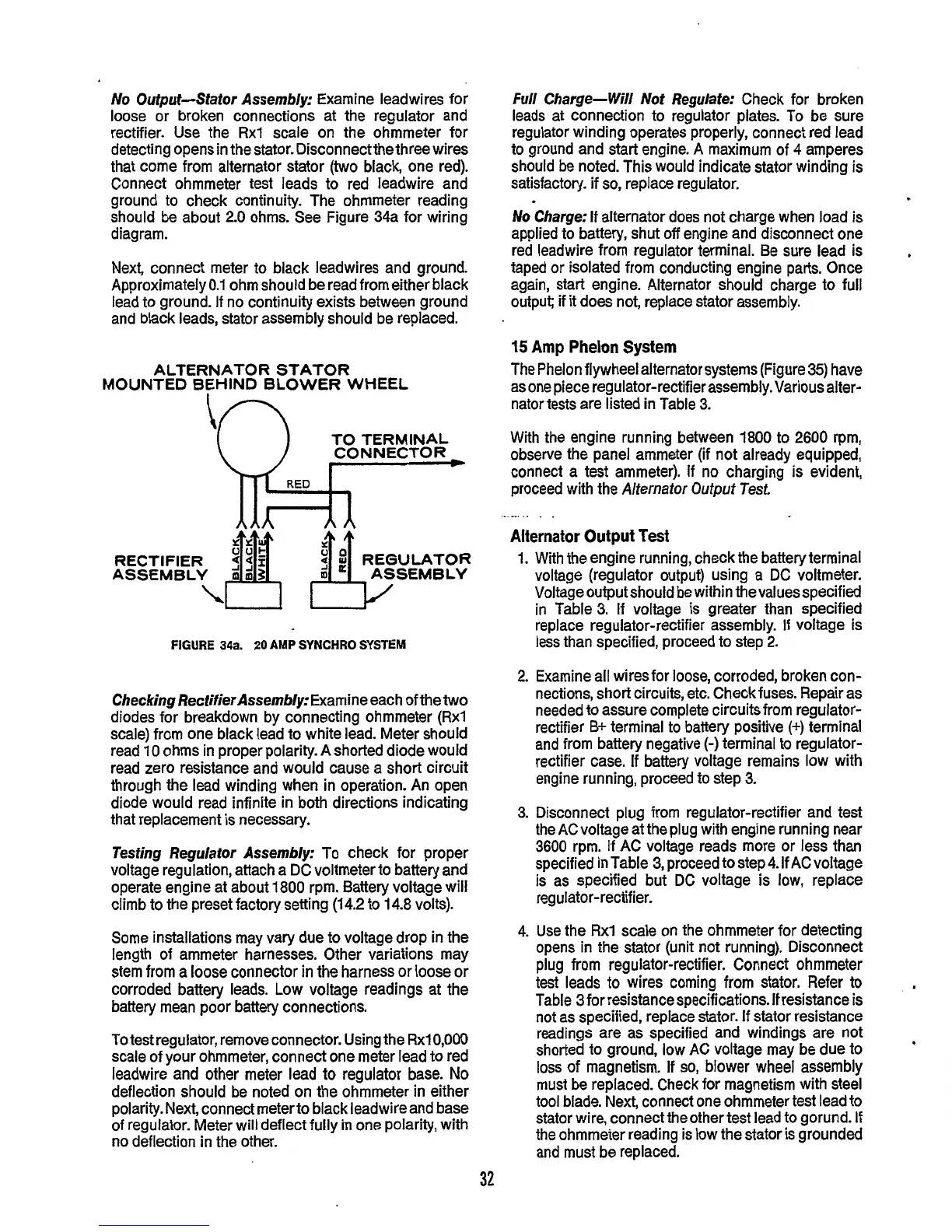

No

Output-Stator Assembly:

Examine leadwires for

loose or broken connections at the regulator and

rectifier. Use the

Rxl

scale on the ohmmeter for

detecting opens in the stator. Disconnectthe three wires

that come from alternator stator

(two

black, one red).

Connect ohmmeter test leads to red leadwire and

ground to check continuity. The ohmmeter reading

should be about 2.0 ohms. See Figure 34a for wiring

diagram.

Next, connect meter to black leadwires and ground.

Approximately0.1 ohm should be read from either black

lead to ground. If no continuity exists between ground

and black leads, stator assembly should be replaced.

ALTERNATOR STATOR

MOUNTED BEHIND BLOWER WHEEL

\n

TO TERMINAL

CONNECTOR

RECTIFIER

ASSEMBLY ASSEMBLY

I

--

-

FIGURE

34a.

20

AMP

SYNCHRO

SYSTEM

Checking RectifierAssembly:

Examine each of the

two

diodes for breakdown by connecting ohmmeter (Rxl

scale) from one black lead to white lead. Meter should

read 10 ohms in proper polarity. A shorted diode would

read zero resistance and would cause a short circuit

through the lead winding when in operation. An open

diode would read infinite in both directions indicating

that replacement is necessary.

Testing Regulator Assembly:

To check for proper

voltage regulation, attach a DC voltmeter to battery and

operate engine at about 1800 rpm. Battery voltage will

climb to the preset factory setting

(14.2

to 14.8 volts).

Some installations may vary due to voltage drop in the

length of ammeter harnesses. Other variations may

stem from a loose connector

in

the harness or loose or

corroded battery leads. Low voltage readings at the

battery mean poor battery connections.

To test regulator, remove connector. Using the Rxl0,OOO

scale of your ohmmeter, connect one meter lead to red

leadwire and other meter lead to regulator base.

No

deflection should be noted on the ohmmeter in either

polarity. Next, connect meter to black leadwire and base

of regulator. Meter will deflect fully in one polarity, with

no deflection in the other.

Full

Charge-

Will

Not Regulate:

Check for broken

leads at connection to regulator plates. To be sure

regulator winding operates properly, connect red lead

to ground and start engine.

A

maximum of

4

amperes

should be noted. This would indicate stator winding is

satisfactory. if

so,

replace regulator.

No

Charge:

If alternator does not charge when load is

applied to battery, shut

off

engine and disconnect one

red leadwire from regulator terminal. Be sure lead is

taped or isolated from conducting engine parts. Once

again, start engine. Alternator should charge to full

output; if

it

does not, replace stator assembly.

6

15

Amp Phelon System

The Phelon flywheel alternator systems (Figure

35)

have

as one piece regulator-rectifier assembly. Various alter-

nator tests are listed in Table

3.

With the engine running between 1800 to 2600 rpm,

observe the panel ammeter (if not already equipped,

connect a test ammeter).

If

no charging is evident,

proceed with the

Alternator

Output

Test,

Alternator Output

Test

...

.

.

.

.

1.

With the engine running, check the battery terminal

voltage (regulator output) using a DC voltmeter.

Voltage output should be within thevaluesspecified

in Table

3.

If voltage is greater than specified

replace regulator-rectifier assembly.

If

voltage is

less than specified, proceed to step

2.

2.

Examine all wires for loose, corroded, broken con-

nections, short circuits, etc. Check fuses. Repair as

needed to assure complete circuits from regulator-

rectifier

B+

terminal to battery positive

(+)

terminal

and from battery negative

(-)

terminal to regulator-

rectifier case.

If

battery voltage remains low with

engine running, proceed

to

step

3.

3.

Disconnect plug from regulator-rectifier and test

the

AC

voltage at the plug with engine running near

3600 rpm. If AC voltage reads more or less than

specified in Table 3, proceed to step 4. If ACvoltage

is as specified but

DC

voltage is low, replace

reg ulator-rectifier.

4.

Use the Rxl scale on the ohmmeter for detecting

opens in the stator (unit not running). Disconnect

plug from regulator-rectifier. Connect ohmmeter

test leads

to

wires coming from stator. Refer to

Table

3

for

resistancespecifications.

If resistance is

not as specified, replace stator. If stator resistance

readings are as specified and windings are not

shorted to ground, low AC voltage may be due to

loss of magnetism. If

so,

blower wheel assembly

must be replaced. Check for magnetism with steel

tool blade. Next, connect one ohmmeter test lead to

stator wire, connect the other test lead to gorund. If

the ohmmeter reading is low the stator

is

grounded

and must be replaced.

32

Loading...

Loading...