1

Warpage occurs chiefly in the upper stem due to its

exposure to intense heat. Out-of-round wear follows

when the seat is pounded by a valve whose head is

not in line with the stem and guide. If

a

valve face is

burned or warped, or

if

the stem is worn, install a new

valve.

Too

much clearance in the intake guide admits air

and oil into the combustion chamber, upsetting

carburetion, increasing oil consumption, and making

heavy carbon deposits. Carbon reduces heat dissi-

pation. Clean metal is a good heat conductor' but

carbon insulates and retains heat. This increases

combustion chamber temperatures which causes

warping and burning.

Unburned carbon residue gums valve stems and

causes them to stick in the guide. Deposits of hard

carbon with sharp points projecting become white

hot and cause pre-ignition and pinging.

Refinish valves that are slightly pitted or burned on an

accurate valve grinder. If valves are badly pitted or

have a thin margin when refacing, replace them.

VT-1020

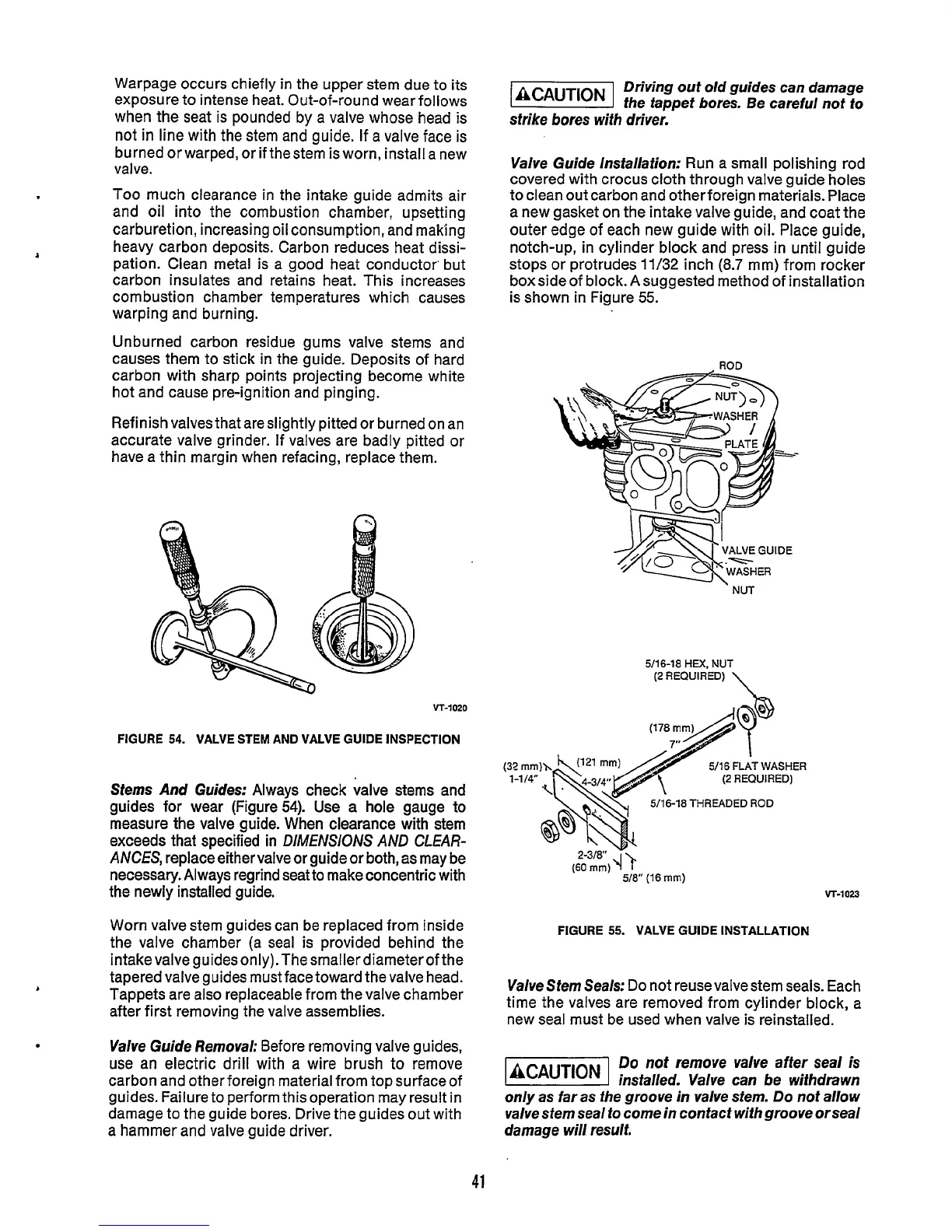

FIGURE

54.

VALVE STEM AND VALVE GUIDE INSPECTION

Sfems And Guides:

Always check valve stems and

guides for wear (Figure

54).

Use

a

hole gauge to

measure the valve guide. When clearance with stem

exceeds that specified in

DIMENSIONS AND CLEAR-

ANCES,

replace either valve or guide or both,

as

may be

necessary. Always regrind seatto make concentric with

the newly installed guide.

Worn valve stem guides can be replaced from inside

the valve chamber (a seal is provided behind the

intake valve guides only). The smaller diameter of the

tapered valve guides must face toward the valve head.

Tappets are also replaceable from the valve chamber

after first removing the valve assemblies.

Valve Guide Removal:

Before removing valve guides,

use

an electric drill with a wire brush

to

remove

carbon and otherforeign material from top surfaceof

guides. Failure to perform this operation may result in

damage

to

the guide bores. Drive the guides out with

a

hammer and valve guide driver.

Driving

out

old guides can damage

fhe tappet bores. Be careful not

to

sfrike bores

wifh

driver.

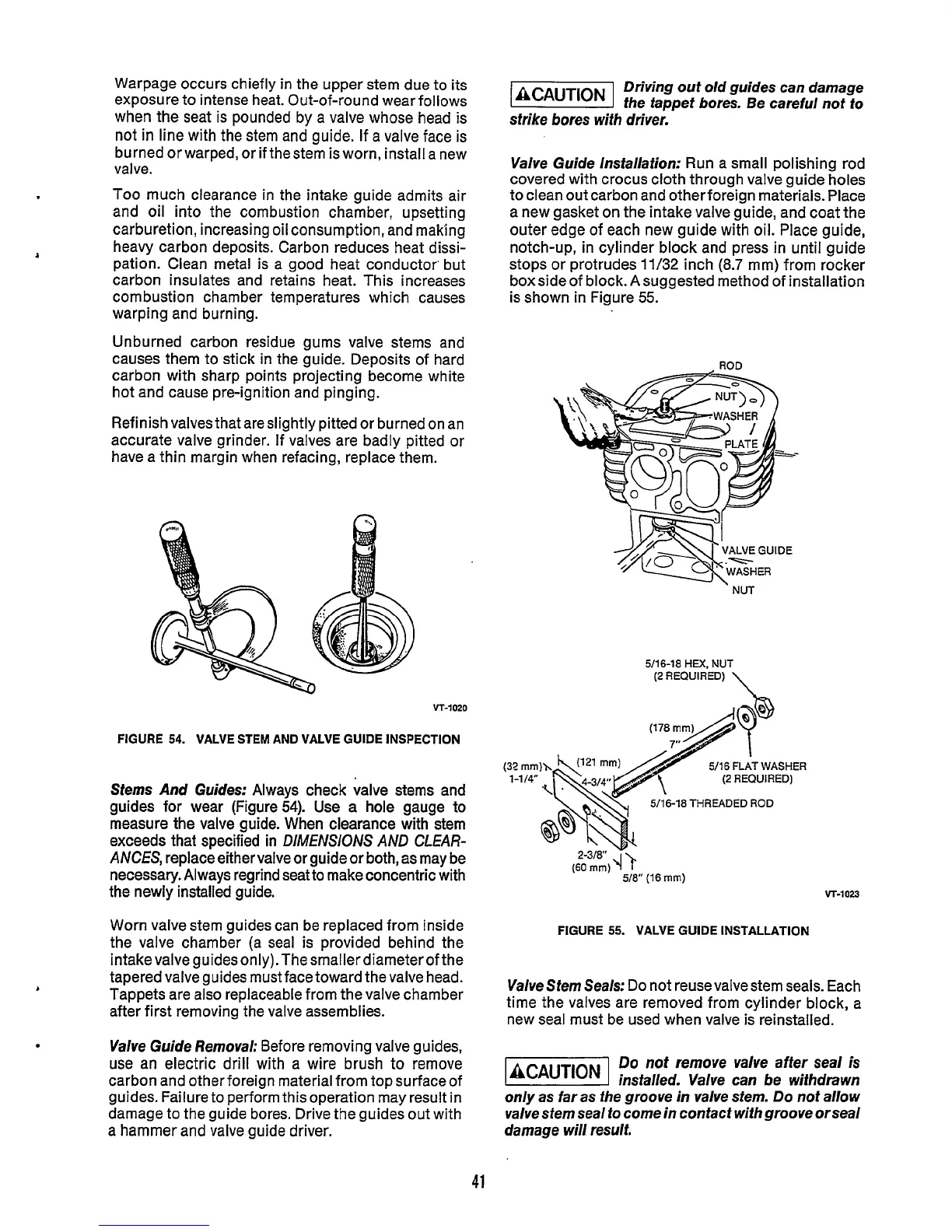

Valve Guide lnsfallafionr

Run a small polishing rod

covered with crocus cloth through valve guide holes

to clean out carbon and otherforeign materials. Place

a new gasket on the intake valve guide, and coat the

outer edge of each new guide with oil. Place guide,

notch-up, in cylinder block and press in until guide

stops or protrudes

11/32

inch

(8.7

mm) from rocker

boxside of block. Asuggested method of installation

is shown in Figure

55.

ROD

'

NUT

5/16-18

HEX.

NUT

\

(2

REQUIRED)

5/16

FLAT

WASHER

(2

REQUIRED)

-18

THREADED ROD

(Elm)

T-

5/8"

(16

mm)

vr-1023

FIGURE

55.

VALVE GUIDE INSTALLATION

Valve Stem Seals:

Do

not reuse valve stem seals. Each

time the valves are removed from cylinder block, a

new seal must be used when valve is reinstalled.

Do

not

remove valve after seal

is

insfalled. Valve can be wifhdrawn

only as far as the groove in valve stem. Do not allow

valve stem seal

fo

come in confacf

wifh

groove orseal

damage will result.

41

Loading...

Loading...