CYLINDER

HEAD

STUD TEST

AND REPLACEMENT PROCEDURE

This cylinder head stud replacement procedure

should be used whenever replacing any of the top six

studs on a NHC block. The use of a Helicoil is not a

recommended repair procedure. If a Helicoil has

been used, thecylinder block must be replaced. Gra-

phoil head and intake manifold gaskets should also

be used when replacing cylinder head studs.

Parts

Required

Part

No.

Description

520-091 2 Step stud

11 0-2987 Head gasket

154-221 9 Intake manifold gasket

420-0398 Drilling fixture (Reusable tool)

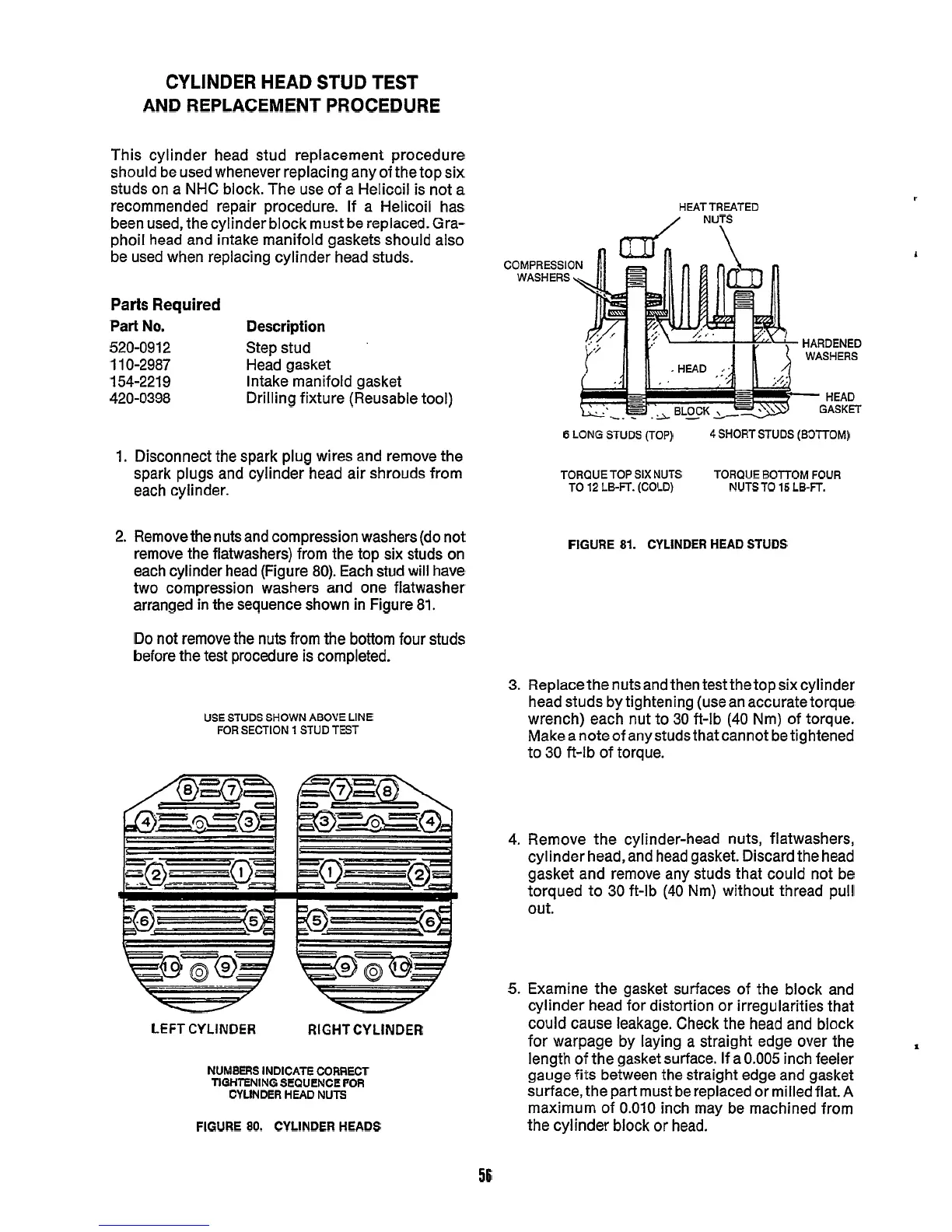

HEATTREATED

d

HARDENED

WASHERS

HEAD

GASKET

-

6

LONG STUDS (TOP)

4

SHORT STUDS (BOTTOM)

1. Disconnect the spark plug wires and remove the

spark plugs and cylinder head air shrouds from

TORQUETOP

SIX

NUTS

TO

12

LB-FT.

(COLD)

TORQUE BOTTOM FOUR

NUTS TO

15

LB-FT.

each cylinder.

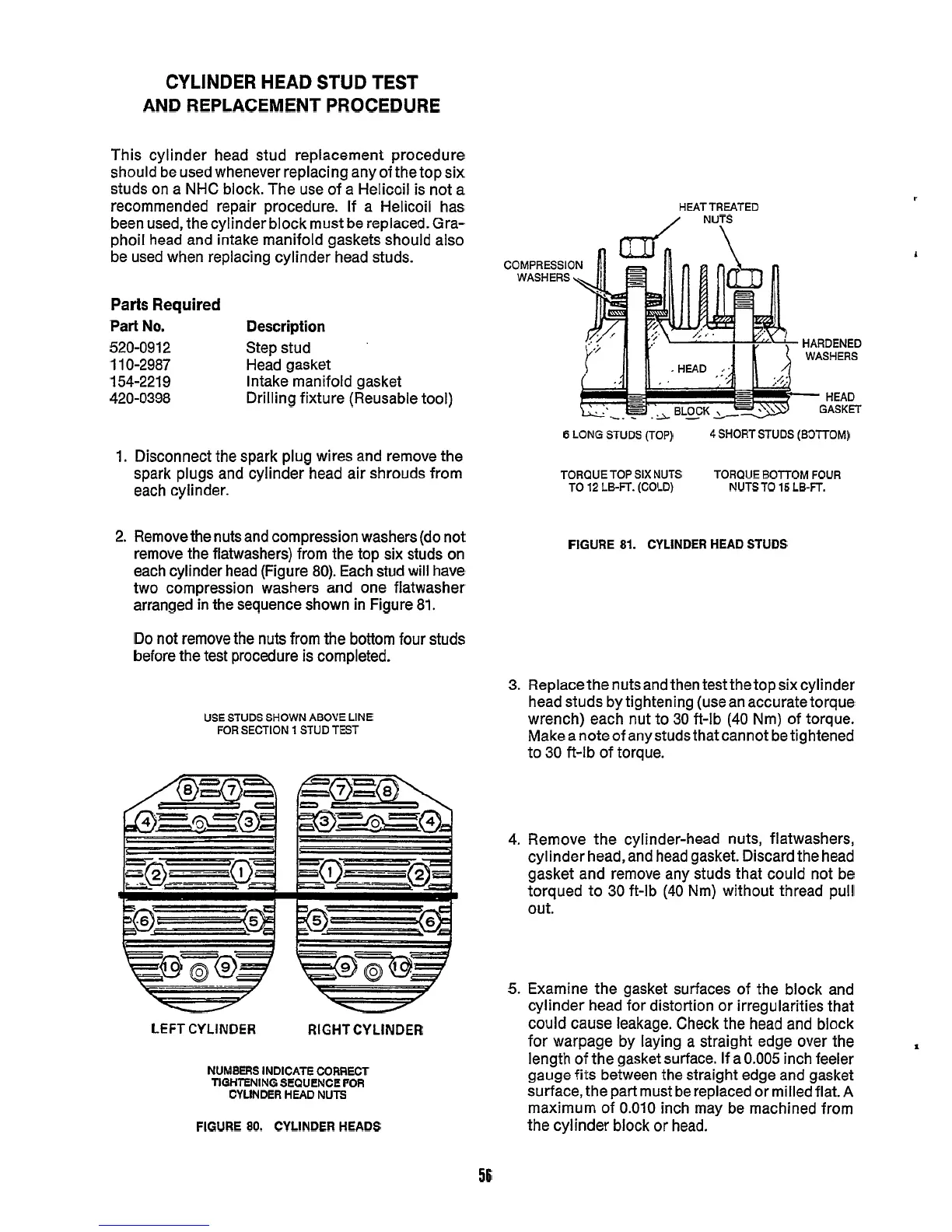

2. Remove the nuts and compression washers (do not

remove the flatwashers) from the top six studs on

each cylinder head (Figure 80). Each stud will have

two compression washers and one flatwasher

arranged in the sequence shown in Figure 81.

Do

not remove the nuts from the bottom four studs

before the test procedure is completed.

USE STUDS SHOWN ABOVE LINE

FOR

SECTION

1

STUD TEST

LEFT

CYLINDER

RIGHT

CYLINDER

NUMBERS INDICATE CORRECT

TIGHTENING SEQUENCE FOR

CYLINDER HEAD NUTS

FIGURE

80.

CYLINDER HEADS

FIGURE

81.

CYLINDER HEAD STUDS

3.

Replace the nuts and then test the top six cylinder

head studs by tightening (use an accurate torque

wrench) each nut to

30

ft-lb (40 Nm) of torque.

Make a note of any studs that cannot be tightened

to

30

ft-lb of torque.

4.

Remove the cylinder-head nuts, flatwashers,

cylinder head, and head gasket. Discard the head

gasket and remove any studs that could not be

torqued to

30

ft-lb (40 Nm) without thread pull

out.

5.

Examine the gasket surfaces of the block and

cylinder head for distortion or irregularities that

could cause leakage. Check the head and block

for warpage by laying a straight edge over the

length of the gasket surface.

If

a

0.005

inch feeler

gauge fits between the straight edge and gasket

surface, the part must be replaced or milled flat.

A

maximum of

0.010

inch may be machined from

the cylinder block or head.

1

56

Loading...

Loading...