2.30

MAINTENANCE

Steering Inspection / Tie Rod Ends and Hubs

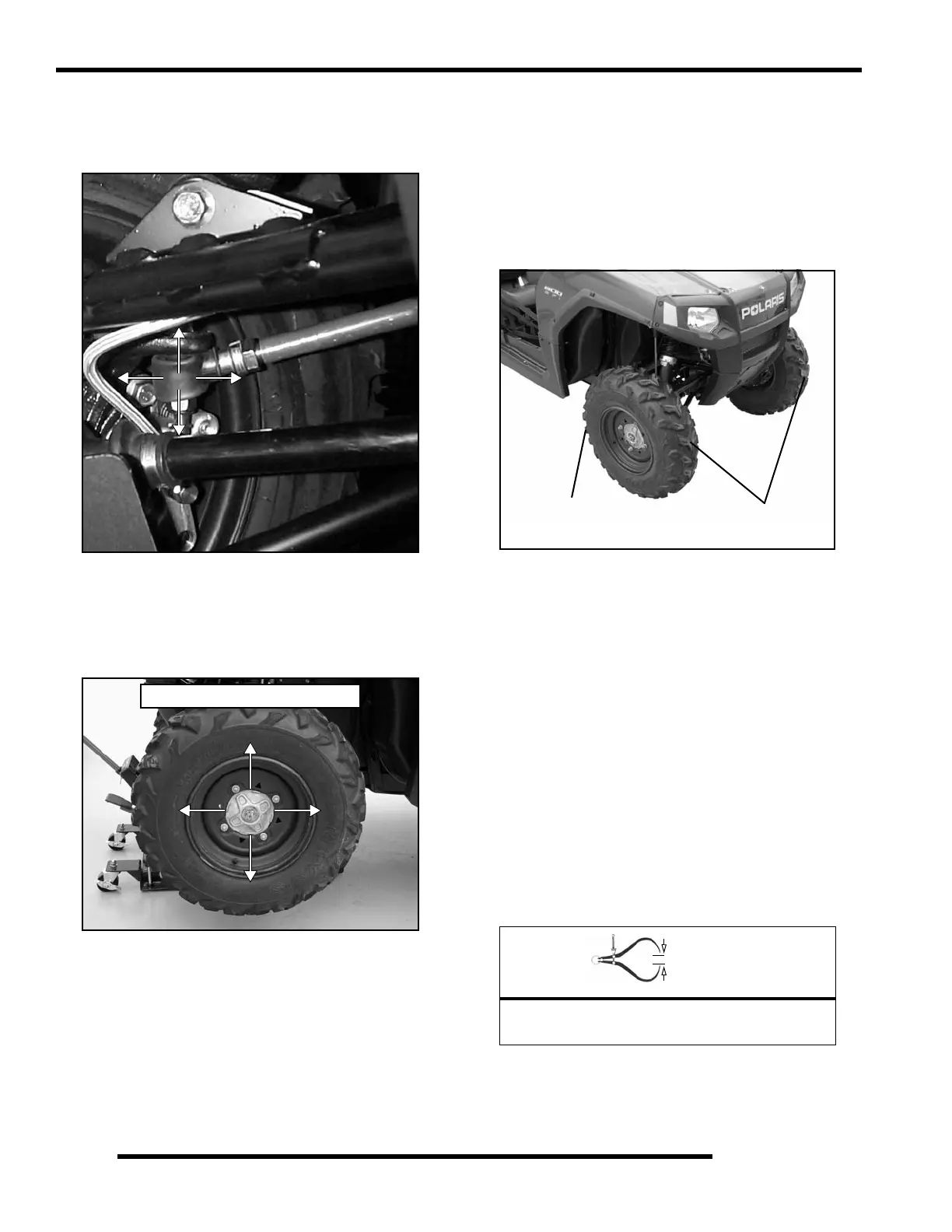

• To check for play in the tie rod end, grasp the steering

tie rod and pull in all directions feeling for movement.

• Elevate front end of machine so front wheels are off the

ground. Check for any looseness in front hub and wheel

assembly by grasping the tire firmly at top and bottom

first, and then at front and rear. Try to move the wheel

and hub by pushing inward and pulling outward.

• If abnormal movement is detected, inspect the hub and

wheel assembly to determine the cause (possible loose

wheel nuts or loose front hub components).

• Refer to Chapter 7 “Final Drive” for front hub service

procedures.

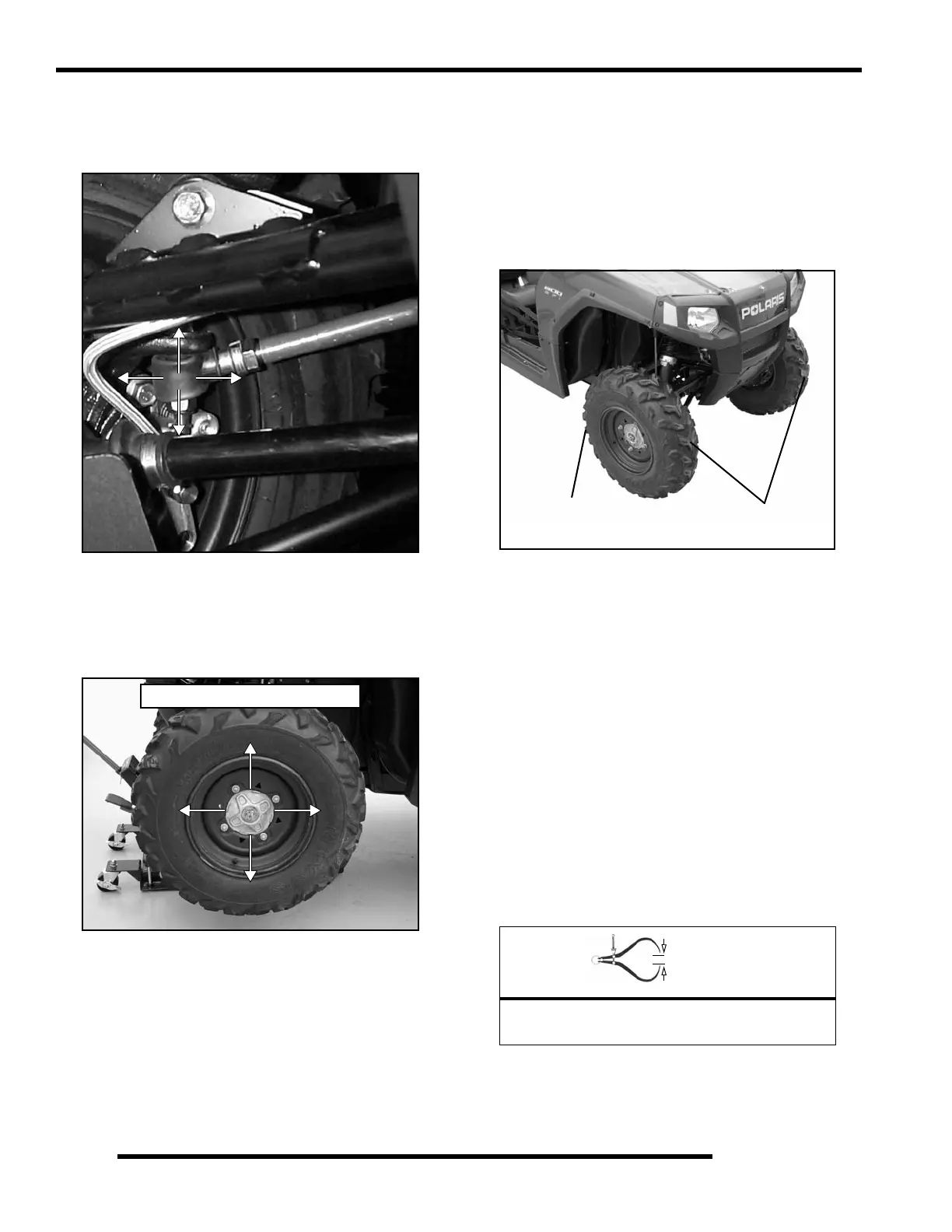

Toe Alignment Inspection

1. Place machine on a smooth level surface.

2. Set steering wheel in a straight ahead position and secure

the steering wheel in this position.

3. Place a chalk mark on the center line of the front tires

approximately 10” (25.4 cm) from the floor or as close to

the hub/axle center line as possible.

NOTE: It is important that the height of both marks

be equally positioned in order to get an accurate

measurement.

4. Measure the distance between the marks and record the

measurement. Call this measurement “A”.

5. Rotate the tires 180

° by moving vehicle forward or

backward. Position chalk marks facing rearward, even with

the hub/axle center line.

6. Again measure the distance between the marks and record.

Call this measurement “B”. Subtract measurement “B”

from measurement “A”. The difference between

measurements “A” and “B” is the vehicle toe alignment.

The recommended vehicle toe tolerance is 1/8” to 1/4”

(.3 to .6 cm) toe out. This means the measurement at the

front of the tire (A) is 1/8” to 1/4” (.3 to .6 cm) wider than

the measurement at the rear (B).

Check for Loose Wheel or Hub

= In. / mm.

Wheel Toe-Out:

(A) - (B) = 1/8 - 1/4" (.3 to .6 cm)

Measurement “B”

Chalk Mark

Measurement “A”

Loading...

Loading...