PROPULSION

6.112004 Four Stroke PWC Service Manual

W ARNING

Before working on the drive system, be sure the lanyard cord and lock plate are removed from the engine stop

switch to kill the ignition or severe injury could result.

Impeller Clearance

1. Remove lanyard cord and lock plate from engine

stop switch. Disconnect battery ground (--) cable.

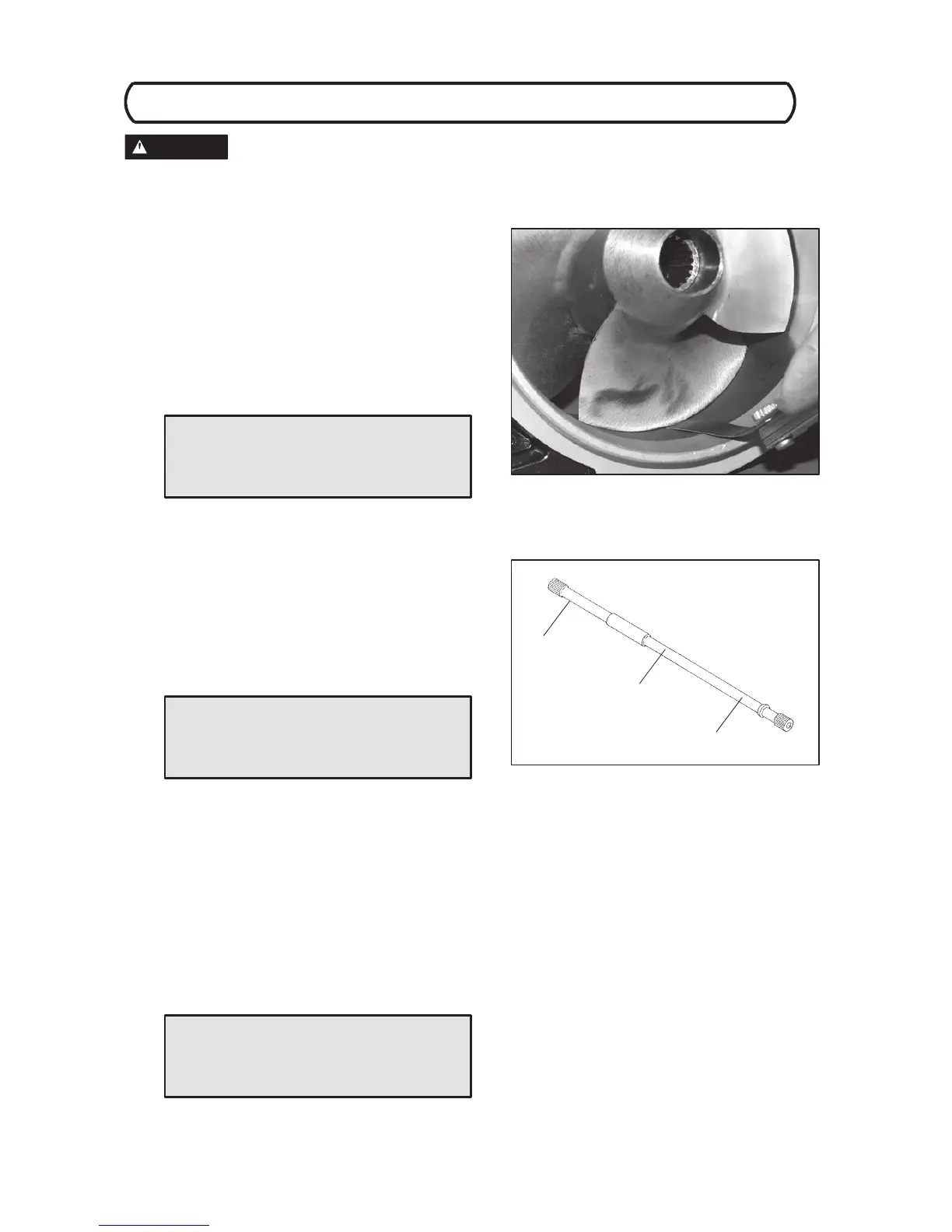

2. Remove intake grate and check impeller to housing

clearance with a feeler gauge. Measure clearance

at leading edge, middle, and trailing edge of each

blade. Replace impeller if clearance exceeds

service limit at any point. If clearance exceeds

service limit with a new impeller, replace pump

housing.

Drive Shaft Inspection

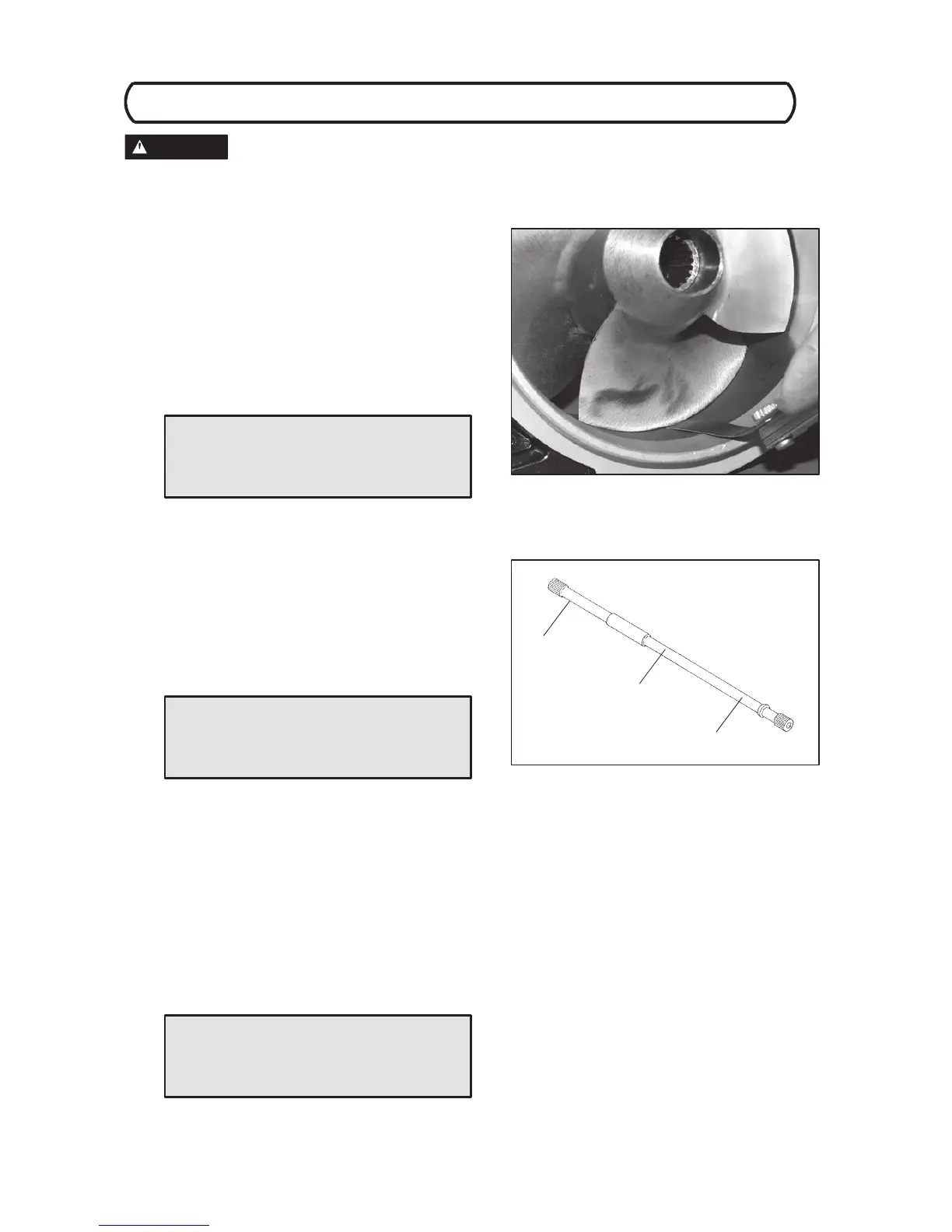

1. Clean driveshaft and support in V - blocks as shown

(C). Measure runout by rotating shaft and

observing dial indicator at point (B). Replace if

runout exceeds the service limit.

NOTE: Excessive driveshaft runout can cause vibra-

tion, bearing, and spline failure. See Pump/Final Drive

T roubleshooting at the end of chapter 2.

2. Inspect driveshaft splines and threads inside

engine drive coupler and impeller carefully for wear

or damage. Replace worn parts. Rubber bumpers

control driveshaft end play. Replace if worn,

cracked or damaged.

NOTE: If driveshaft, impeller, or coupler threads are

worn or damaged, improper pump-to-hull, or pump-to-

engine alignment should be suspected. Refer to Pump/

Drive shaft Alignment on pages 5.13 -- 5.14 for more in-

form a ti o n .

Impeller Clearance

Std: .002 - .008″ (.05 - .20 mm)

Service Limit: .020″ (.5 mm)

C

B

C

Place dial indicator

at (B)

Support in V -blocks

at (C)

Drive Shaft Runout

Service Limit: .005″ (.13mm)

Drive Shaft End Play

.100-.200″ (2.54-5.08mm)

Loading...

Loading...