32

1 Preventative Maintenance Schedule

1.1 Mechanical Inspection

The door area should always be kept clear of dirt, rocks or any other substances in order to insure proper operation.

Maintenance of the door operator should be performed according to the schedule in Table 8.

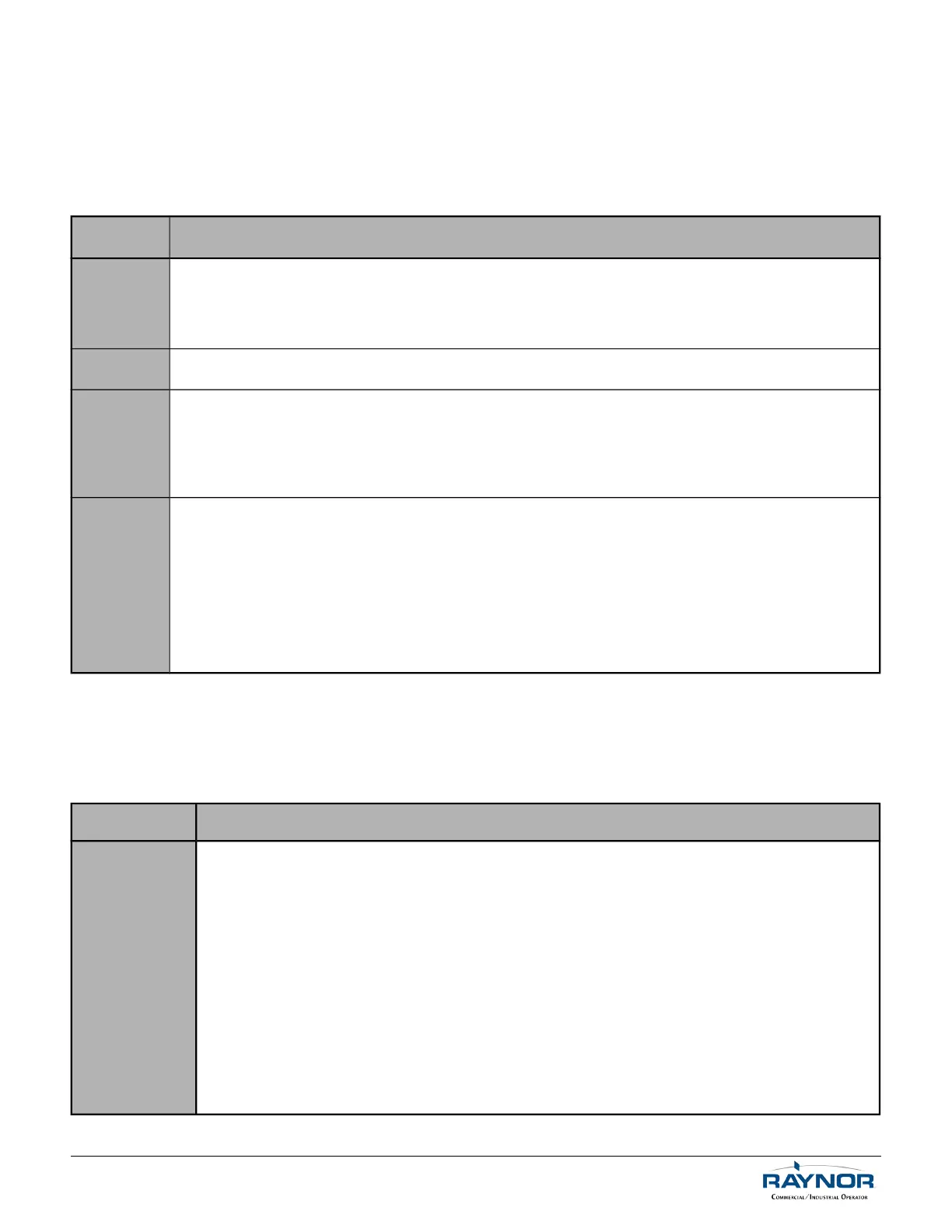

Table 8 - Mechanical Inspection Schedule (Part 1)

Time

Frame

Inspection

Every

Month

• Test the door’s safety features.

• Verify the brake function (if applicable).

• After adjusting either the clutch or the limit's travel, retest the operator’s safety features.

• Verify gear reducer's oil level (if applicable).

Every

3 Months

• Verify and adjust the clutch if necessary.

Every

6 Months

• Lubricate all moving parts. Bushings are oil impregnated and are lubricated for life.

• Verify that all mechanical parts function properly.

• Inspect the V-belt and adjust or replace if necessary.

• Manually operate the door. If the door does not open or close freely, correct the cause of the

malfunction.

Once a

Year

• Run the operator a few cycles:

◦ Make sure that the door rollers are rolling smoothly on the track.

◦ Listen to the motor: The motor should hum quietly and smoothly.

◦ Verify that the limits operate quietly and smoothly: investigate any unusual noise.

• Verify that the mounting bolts are holding the unit securely.

• Inspect the unit for evidence of corrosion.

• Change the gear reducer's oil, at the very least, after every 2500 hours of operation or once a

year (if applicable).

1.2 Electrical Inspection

It is recommended that the electrical maintenance inspections be performed at the same intervals as the mechanical

maintenance inspections.

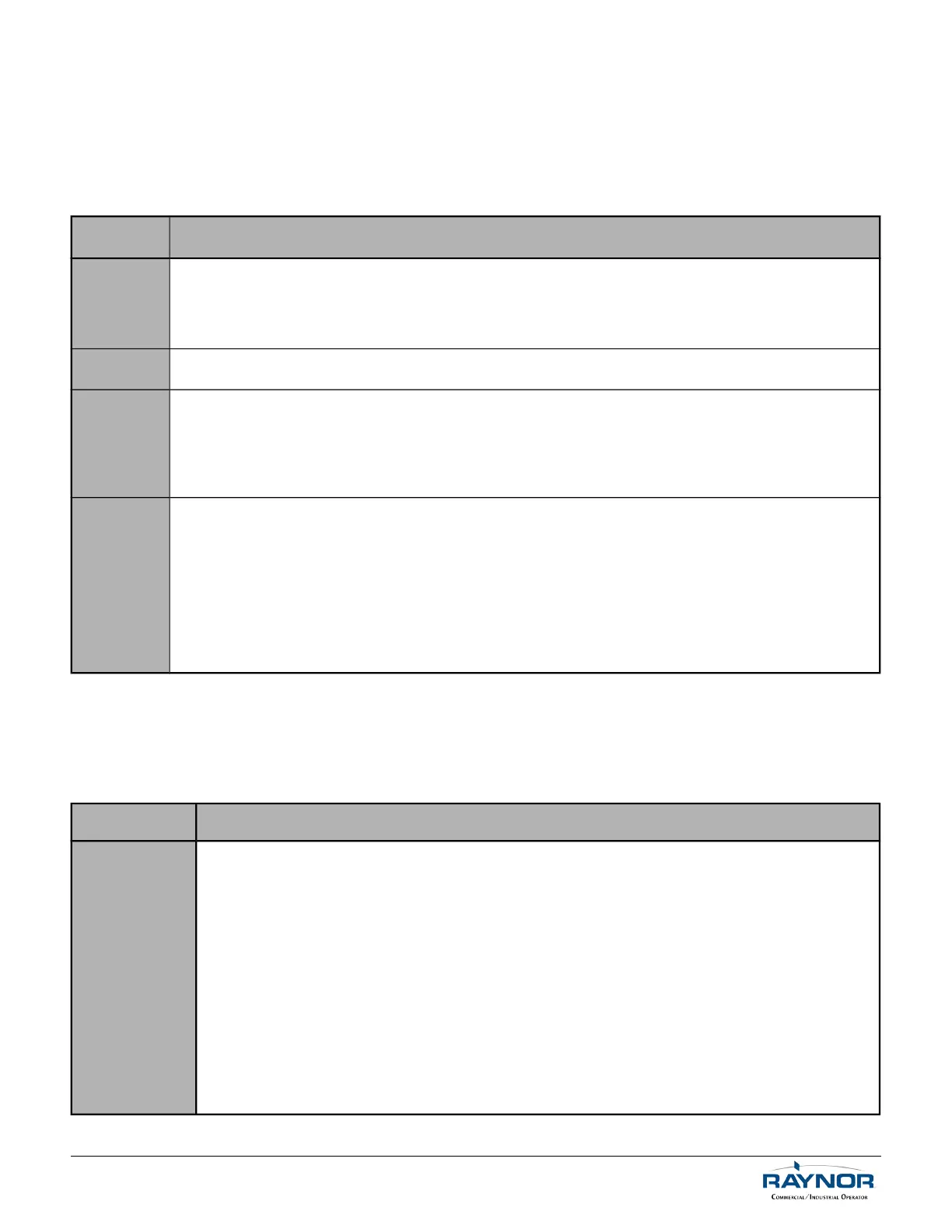

Table 9 - Electrical Inspection

Time Frame Inspection

Every Month

Inspect the unit for evidence of corrosion on electrical wires and connectors.

Inspect the wiring compartment and remove any dirt from the control units.

Verify all the grounding wires and terminals for corrosion. Be particularly careful to verify the

ground wires.

Verify the terminal strips to insure that all the screws are tightened.

Verify that the pneumatic edge or other entrapment protection devices installed on the

operator are fully operational.

Verify the voltage at the input terminals while the operator is running. The voltage must not drop

more than 10% momentarily. If the voltage drop is too deep when running, the relays may

chatter and the contact points will wear prematurely and may eventually seize. Verify the power

terminals for corrosion.

Verify the current consumption of the unit with an amp-meter. The current value should be

consistent with the nameplate specifications. Investigate any anomaly.

For technical support, please call 1-800-4-Raynor (1-800-472-9667) or visit www.raynor.com

Loading...

Loading...