24

I-SCE (09-18) PN207697R9

GAS PIPING AND PRESSURES—CONTINUED

Instructions to Check Valve Outlet (Manifold) Pressure

NOTE: A manometer (fluid-filled gauge) is recommended rather than a spring-type gauge due to

the difficulty of maintaining calibration of a spring-type gauge.

1. With the manual valve (on the combination valve) positioned to prevent flow to the main burners, connect a

manometer to the 1/8-inch pipe outlet pressure tap in the valve.

2. Open the valve and operate the heater. Measure the gas pressure to the manifold. To measure the low-stage

pressure on units equipped with a two-stage valve, disconnect the wire from the HI terminal on the valve. Be

sure to reconnect the wire.

3. Normally, adjustments to the factory-preset regulator should not be necessary. If adjustment is necessary, set

pressure to correct settings by turning the regulator screw IN (clockwise) to increase pressure. Turn the regulator

screw OUT (counterclockwise) to decrease pressure. Consult the valve manufacturer’s literature provided with

the furnace for more detailed information.

ELECTRICAL SUPPLY AND CONNECTIONS

• All electrical wiring must be completed in accordance with local, state, and national codes and regulations and

with the National Electric Code (ANSI/NFPA 70) or, in Canada, the Canadian Electric Code, Part 1 (CSA C.22.1).

• Check any local ordinances or gas company requirements that apply.

• Check the rating plate on the heater for the supply voltage and for current requirements. A separate line voltage

supply with fused disconnect switch should be run directly from the main electrical panel to the unit, making

connections in the junction box (see Figure 2).

• Seal all electrical entrance openings with field-supplied bushings.

• Refer to Table 12 for field-supplied wiring sizes—from disconnect to electrical box—for connection to the motor

contactor or starter.

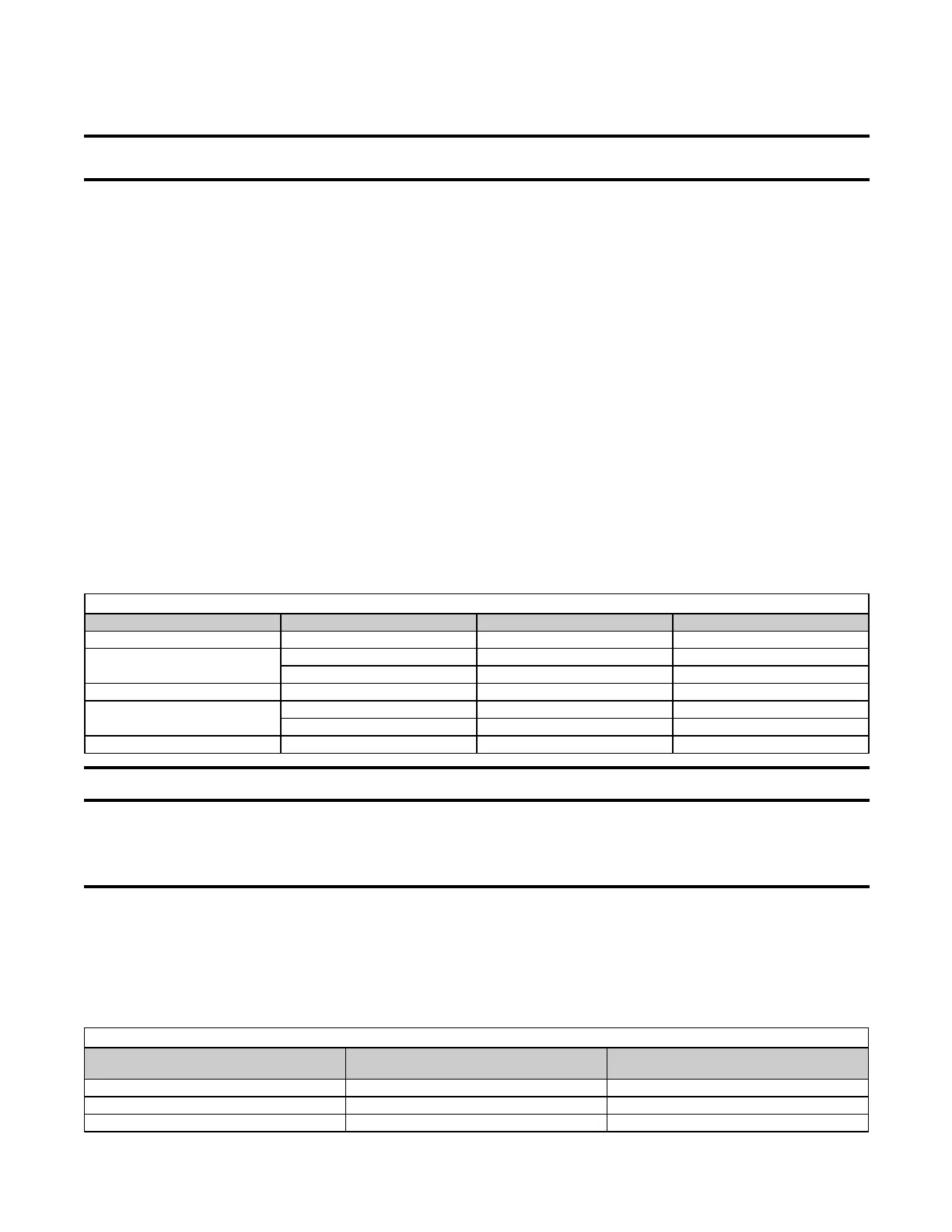

Table 12. Field-Supplied Wiring Sizes

Voltage/Phase Motor HP Wire Gauge BX Cable

120/1 1/4– 1/2 14 3/8

208–230/1

1 12 3/8

1–1-1/2 14 3/8

208–230/3 1/4–3 14 3/8

460/3

5 12 3/8

1/4–5 14 3/8

575/3 1/2–5 14 3/8

⚠ CAUTION ⚠

If any of the original wire as supplied with the appliance must be replaced, it must be replaced

with wiring material having a temperature rating of at least 105°C, except for the sensor lead and

the optional bypass damper combustion air safety circuit (option AG39 or AG40) wires, which must

be rated at 150°C.

• A disconnect switch is available as optional equipment or may be supplied locally. When installing the disconnect

switch, ensure that the conduit and switch housing are clear of all service panels. Allow at least 4 feet (1.2 M)

of service room between the disconnect switch and any removable service panels. When providing or replacing

fuses in a fusible disconnect switch, use dual-element time delay fuses sized at 1.25 × maximum total input amps.

• The heater is equipped with a low-voltage (24V) control circuit.

• Refer to Table 13 for field-supplied control wiring sizes.

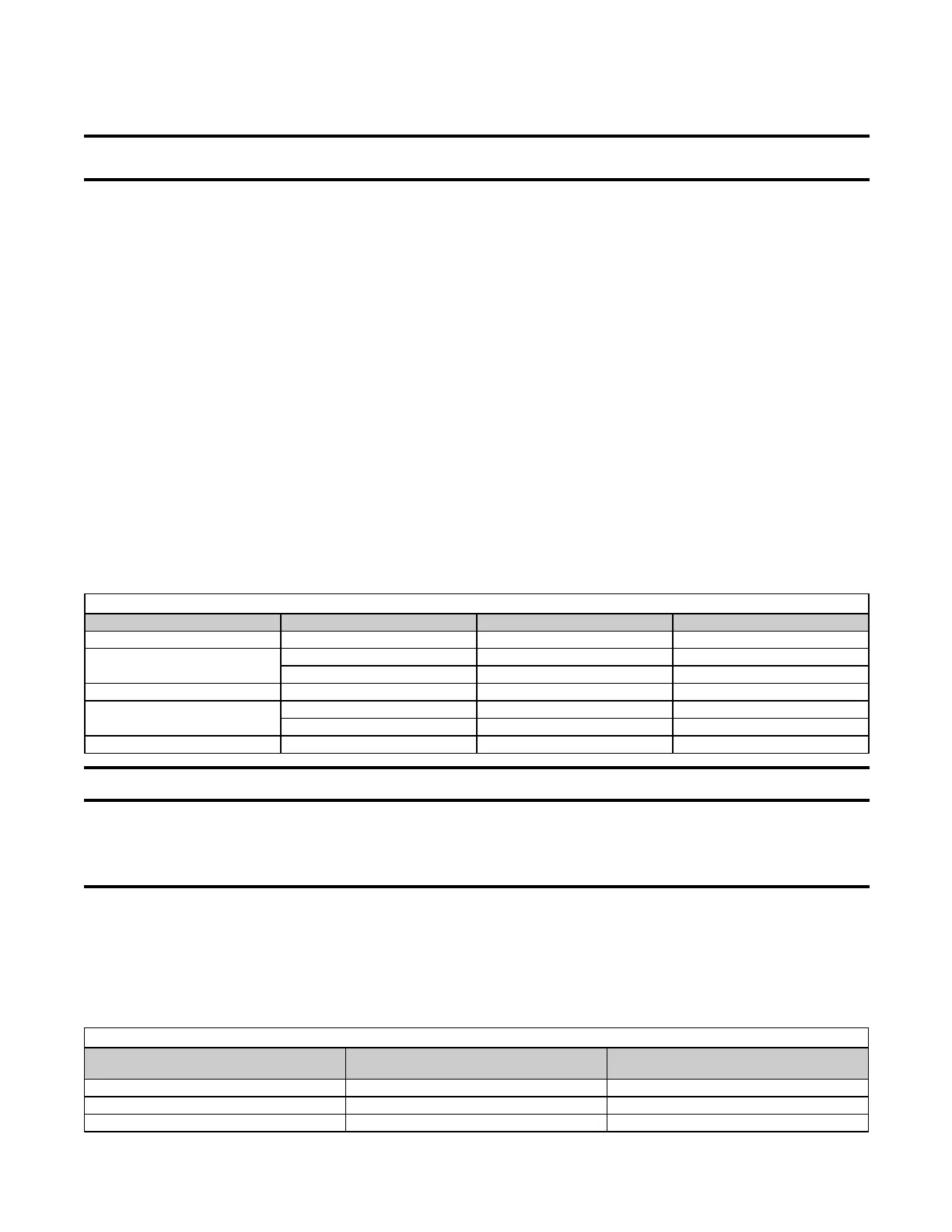

Table 13. Field-Supplied Control Wiring Sizes

Distance from Unit to Control

(Feet (Meters))

Minimum Recommended Wire Gauge

(AWG)

Total Wire Length

(Feet (Meters))

75 (23) #18 150 (46)

125 (38) #16 250 (76)

175 (53) #14 350 (107)

Loading...

Loading...