8

I-SCE (09-18) PN207697R9

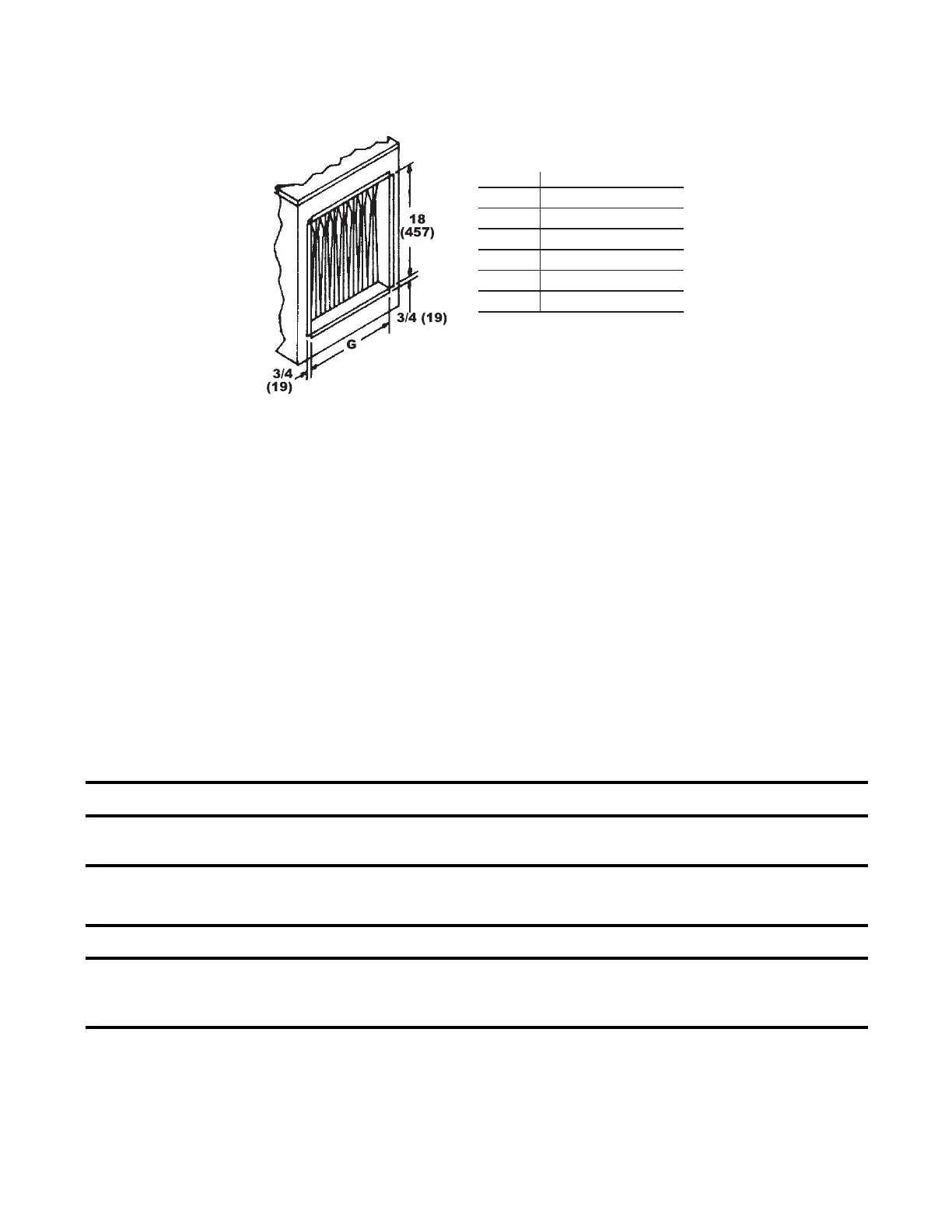

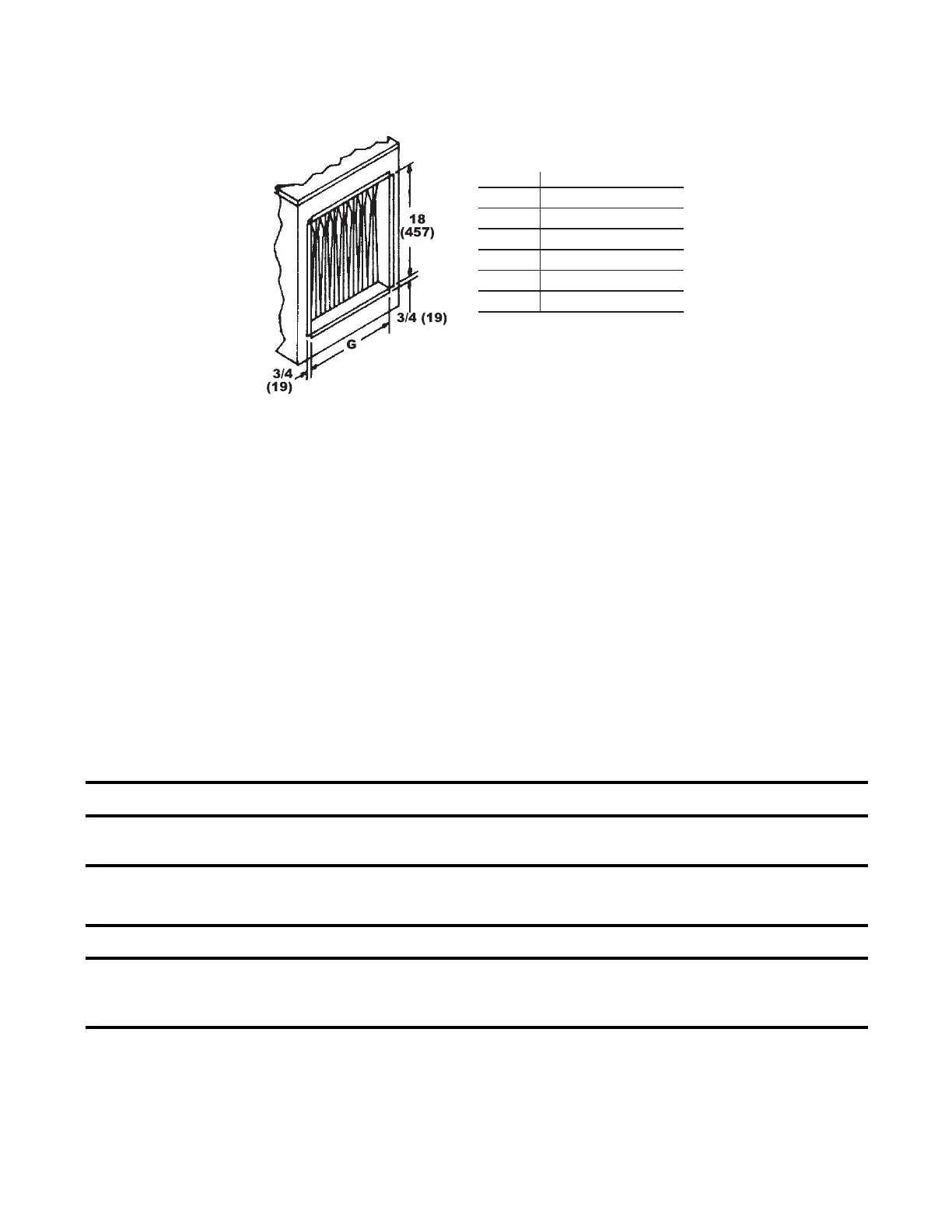

DUCT CONNECTIONS

Refer to Figure 6 for duct connection dimensions.

Size G

125 15-1/4" (387mm)

150, 175 20-3/4" (527mm)

200, 225 26-1/4" (667mm)

250, 300 34-1/2" (876mm)

350 40" (1016mm)

400 45-1/2" (1156mm)

Figure 6. Duct Connection Dimensions

Requirements and Suggestions for Connecting and Installing Ducts

• Type of Ductwork: The type of duct installation to be used depends in part on the construction type of the roof—

whether wood or steel bar joist, steel truss, or pre-cast concrete—and the ceiling—whether hung, flush, etc.

• Ductwork Material: Rectangular duct should be constructed of galvanized iron—not lighter than No. 26 US gauge

—or aluminum—No. 24 B&S gauge.

• Ductwork Structure: All duct sections 24 inches (610 mm) or wider and over 48 inches (1219 mm) in length

should be cross-broken on top and bottom and should have standing seams or angle-iron braces. Joints should

be S and drive strip or locked.

• Through Masonry Walls: No warm air duct should come in contact with masonry walls. Insulate around all air

duct through masonry walls with 1-inch (not less than 1/2-inch) of insulation.

• Through Unheated Space: Insulate all exposed warm air ducts passing through an unheated space with 1-inch

(not less than 1/2-inch) of insulation.

• Duct Supports: Suspend all ducts securely from adjacent buildings members. Do not support ducts from unit

duct connections.

• Duct Sizing: Proper sizing of the supply air ductwork is necessary to ensure a satisfactory heating installation. The

recognized authority for duct size is the Air Conditioning Contractor’s Association, 2800 Shirlington Road, Suite 300,

Arlington, VA 22206 (www.acca.org). A manual covering duct sizing in detail may be purchased directly from them.

⚠ CAUTION ⚠

To prevent possible motor overloading, ensure that the external duct system static pressure is

within the limits shown on the rating plate and that the motor pulley and belt are properly adjusted.

• Horizontal Discharge Duct Length: To reduce losses at the furnace outlet, a minimum horizontal duct run of 24

inches (610 mm) is recommended before turns or branches are made in the duct system.

⚠ CAUTION ⚠

The joint where the supply air duct attaches to the furnace must be sealed securely to prevent

air leakage into draft hood or burner rack area. Leakage can cause poor combustion and pilot

problems, can shorten heat exchanger life, and can cause poor performance.

Loading...

Loading...