28

I-SCE (09-18) PN207697R9

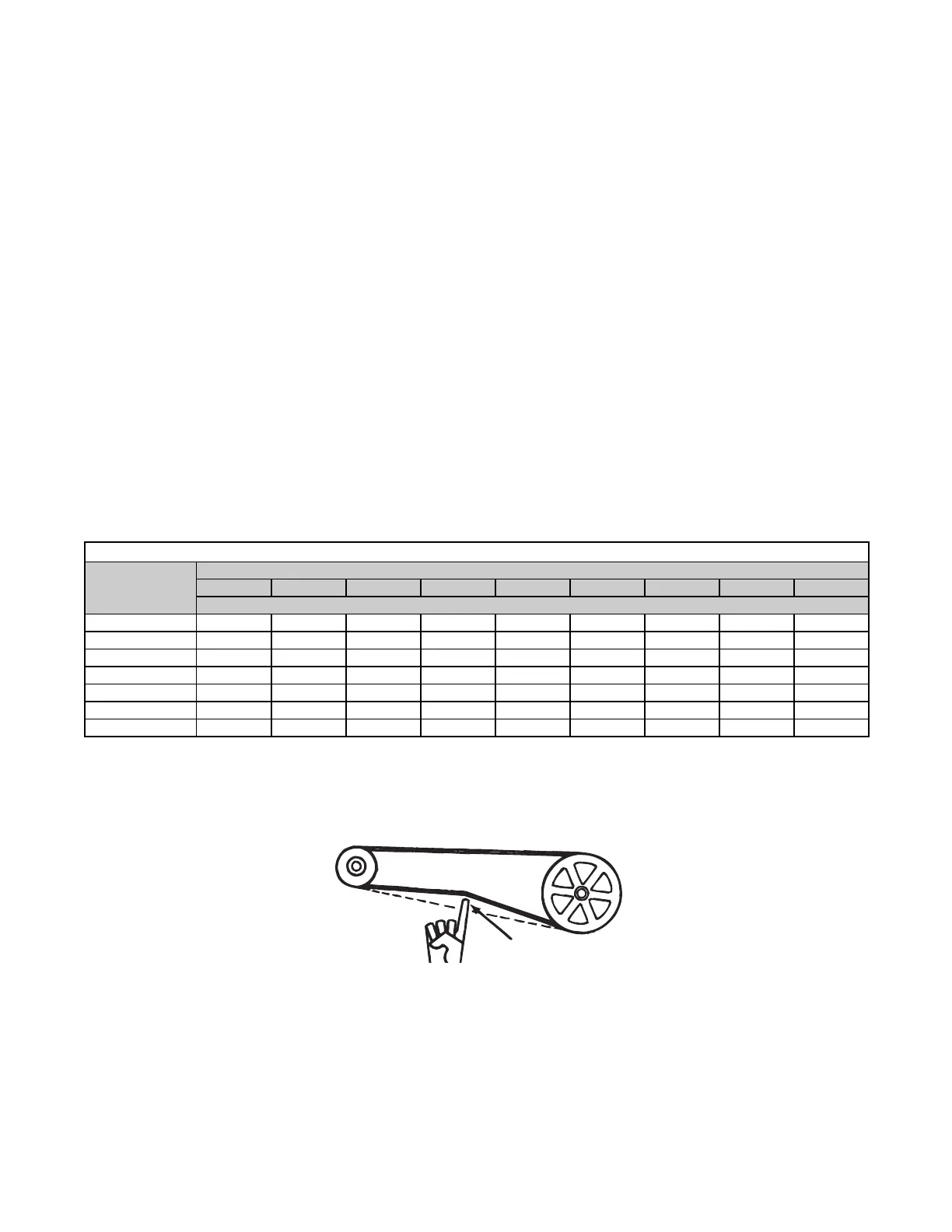

Table 16. FLA of Blower Motors (Open, Single-Speed, Average Values)

Voltage/Phase

HP

1/4 1/3 1/2 3/4 1 1-1/2 2 3 5

FLA

115V/1PH 4.60 5.60 8.80 11.00 13.00 18.20 20.40 24.80 —

208V/1PH 2.50 3.10 5.10 6.10 7.20 10.10 11.30 13.70 28.00

230V/1PH 2.30 2.80 4.40 5.50 6.50 9.10 10.20 12.40 26.00

208V/3PH 1.70 1.80 2.20 2.90 3.60 5.80 7.30 9.30 14.60

230V/3PH 1.50 1.60 2.00 2.60 3.20 5.20 6.60 8.40 13.20

460V/3PH 0.75 0.80 1.00 1.30 1.60 2.60 3.30 4.20 6.60

575V/3PH — — — — 1.30 2.10 2.60 3.40 5.30

BELTS, BLOWERS, AND DRIVES

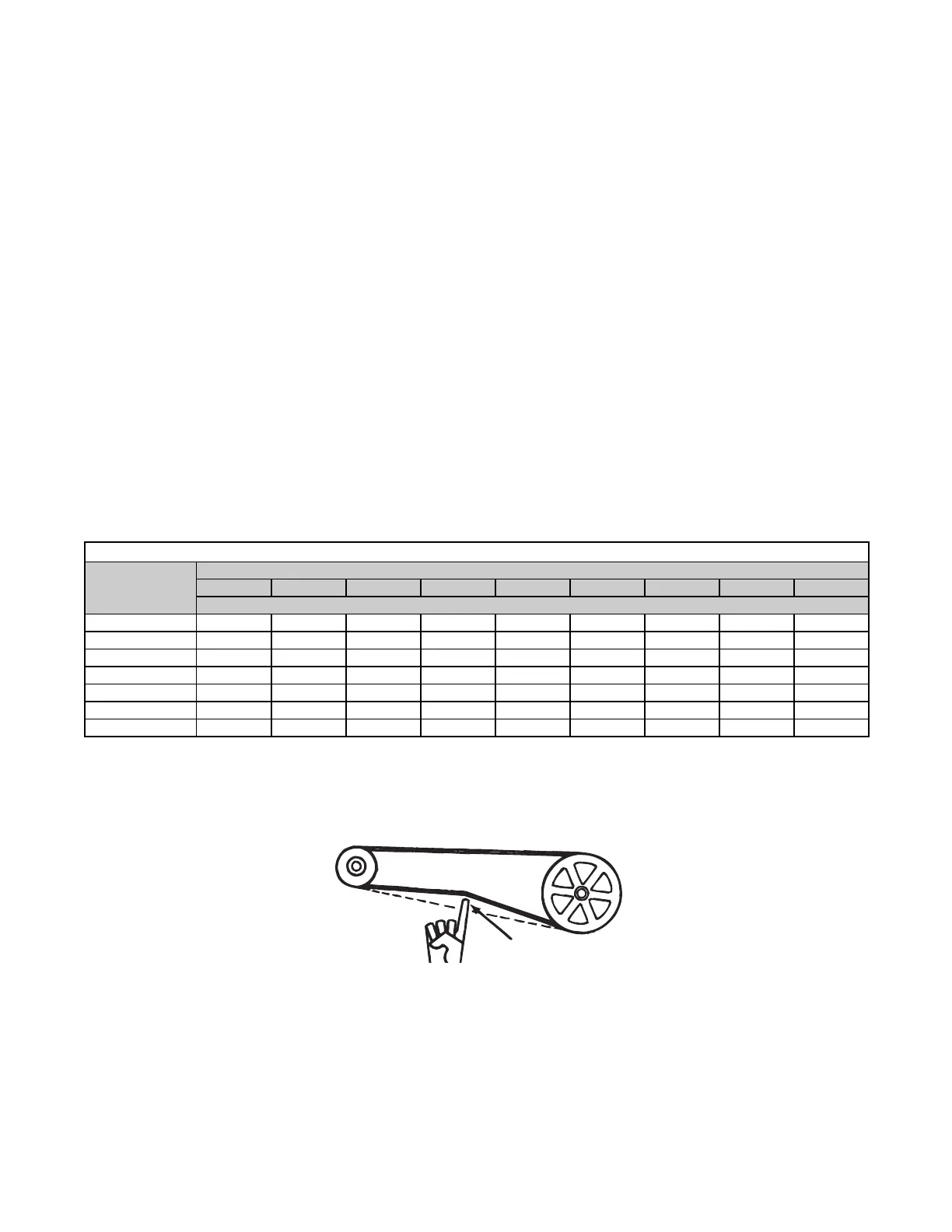

Checking and Adjusting Belt Tension

Proper belt tension is important to the long life of the belt and motor. A loose belt will cause wear and slippage. Too

much tension will cause excessive motor and blower bearing wear. Check belt tension as shown in Figure 23.

3/4" (19 mm)

BLOWER FAN CONTROL—CONTINUED

The blower fan is controlled as follows:

• After the gas valve opens, there is a time delay of blower fan operation to prevent the discharge of cold air.

• Blower fan operation continues after the thermostat is satisfied, as determined by the fan time delay.

• To ensure that the blower fan can continue to operate, the power supply to the furnace MUST NOT be interrupted

except for when servicing the unit.

• If the customer wants the furnace off at night, the gas valve circuit SHOULD BE OPENED by a single-pole switch

wired in series with the thermostat. Some thermostats are provided with this feature. Multiple units controlled from

a single thermostat are shut off in the same manner. For proper operation, ensure that the blower fan control is

wired correctly.

LIMIT CONTROL

All models are equipped with an automatic, nonadjustable, reset limit control that acts to interrupt the electric supply

to the redundant main operating valve in case of motor failure or lack of airflow due to restrictions at the inlet or outlet.

MOTOR LOAD AND AMPS

• Amps may be adjusted downward by reducing blower rpm or by increasing duct system static pressure. Use an

ammeter to check blower motor amps.

• See the motor rating plate for exact motor specifications. Do not exceed the amp rating on the motor nameplate.

• Venter motor amps are 1.5 amps for a 115- or 575-volt unit or 0.8 amps for a 208-, 230-, or 460-volt unit.

• Table 16, which lists the Full Load Amps (FLA) of blower motors (open) based on Horsepower (HP) and Voltage

(V), can be used for sizing line wiring but should not be interpreted as the exact motor amps.

Figure 23. Checking Belt Tension

If the belt cannot be depressed 3/4 inches (19 mm), as shown in Figure 23, adjust the belt tension as follows:

1. Ensure that belt is aligned in pulley grooves properly and is not angled from pulley to pulley.

2. Loosen adjusting screw locknut on motor base and turn adjusting screw until belt can be depressed 3/4 inches

(19 mm).

3. When correct belt tension is achieved, retighten adjusting screw locknut.

Loading...

Loading...