Rockwell Automation Publication 750-PM101B-EN-P - April 2022 55

Chapter 3 PowerFlex 755T Control Block Diagrams

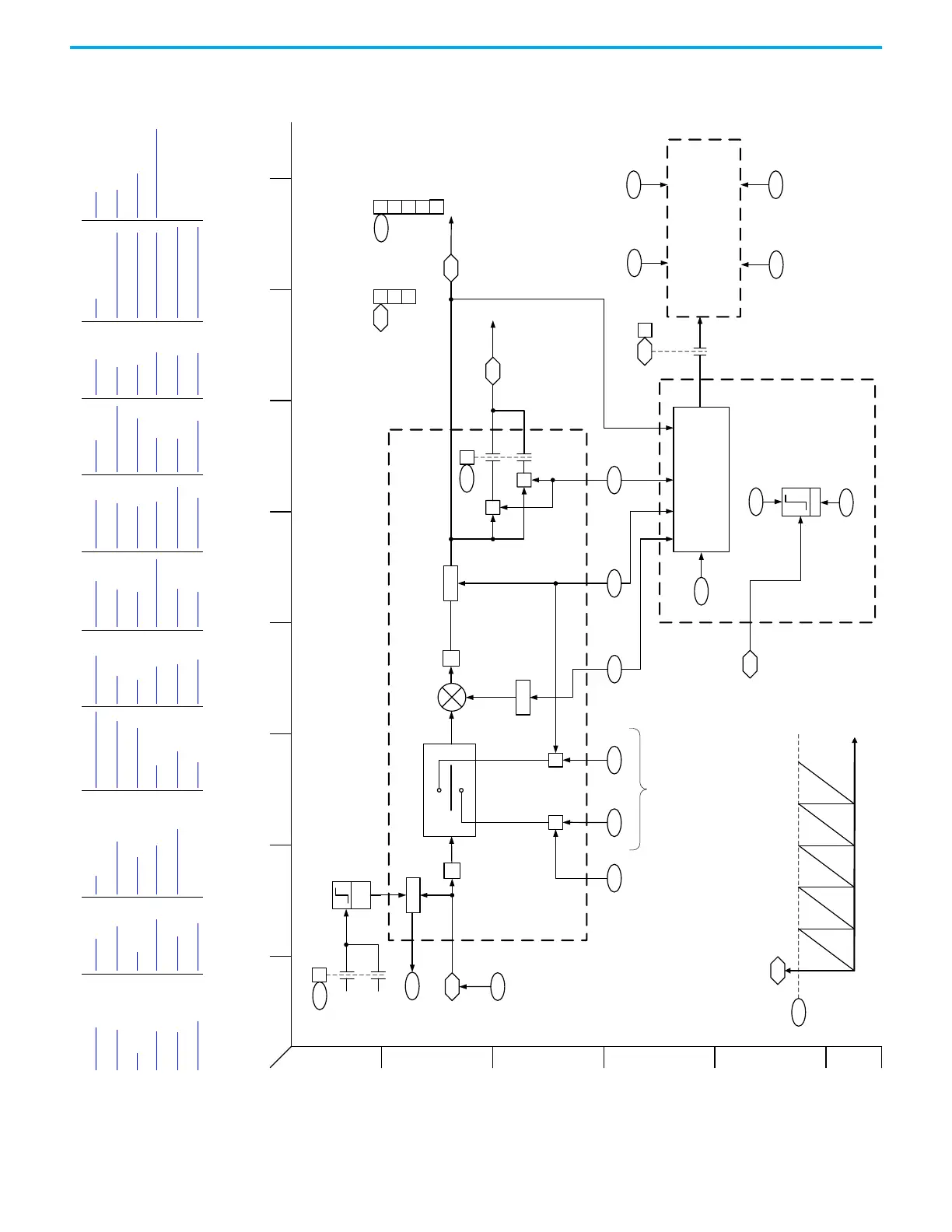

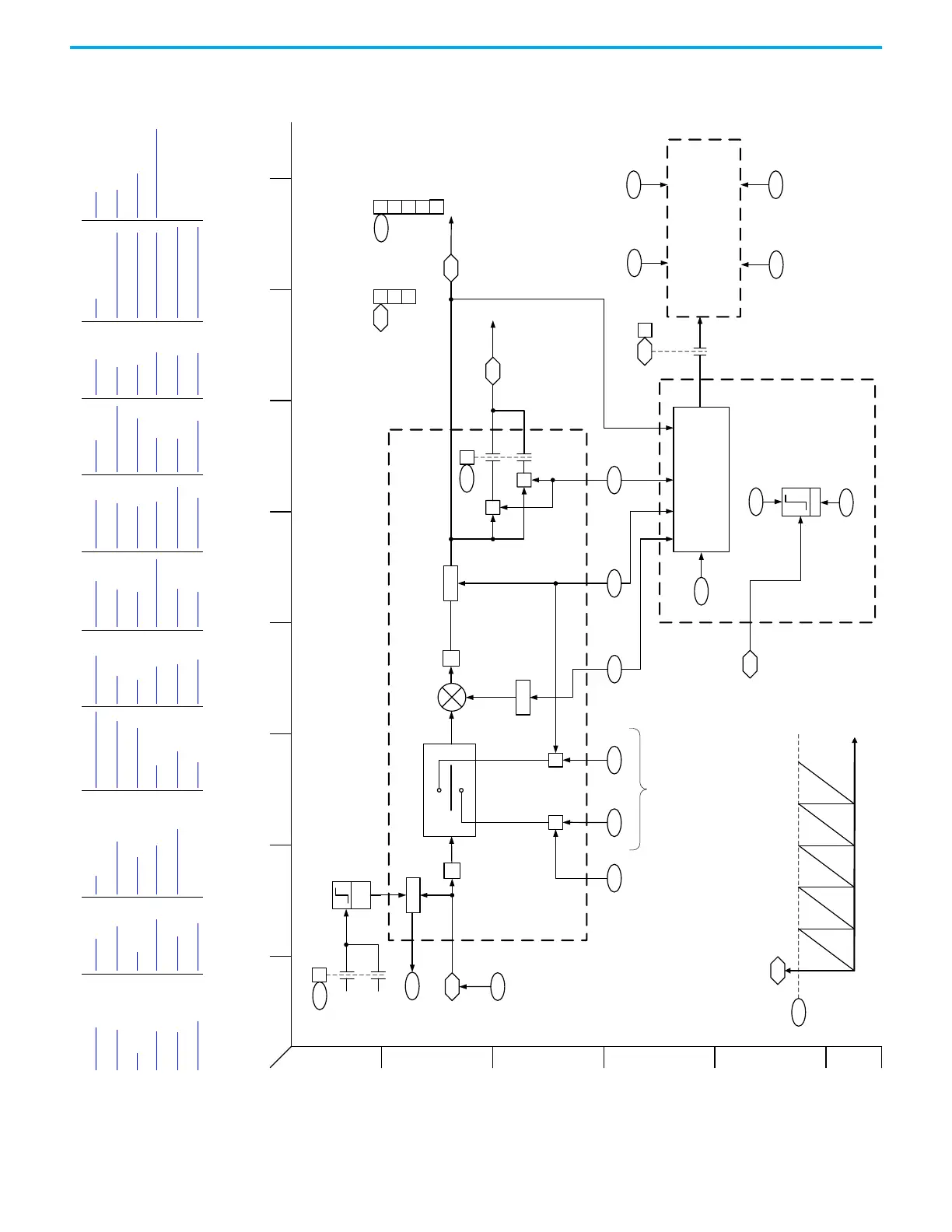

Figure 34 - Position Control – Spindle Orient

[ ]

[ ]

EGR

1

2

3

4

5

6

BA

D

C

FHEG

I

X X

Preg Fb Sel

1013

1063

ReCap

6

Mod

0

1

At SO Speed

Mode

1061

+

-

1069

1070

1063

SO Oset

SO Oset

Modulo Divider

SO Position Out

SO Unit Out

1064

SO EPR Input

1065

SO Rvls Input

1066

SO Rvls Output

1067

SO Cnts per Rvls

SO Status

1068

SO Unit Scale

1069

SO Position Out

1067

SO Cnts per Rvls

Position Fb

Gear Ratio

1746

0

X

*1 *1

*1: Product need to be within 32-bits integer range

Position Feedback Input

Position Control – Spindle Orient

(Spindle)

2

Orient Cplt

0

1

Home DI

Home DI Inv

SO Cong

2

Recap Hm Psn

1060

3

ShortestPath

4

Scale Invert

Spindle Position Indicator

Vref Ramped

1923

Spindle Position Command

Spindle Position Planner

1062

SO Setpoint

1071

SO Accel Time

1072

SO Decel Time

1073

SO Vel Lim Fwd

SO Vel Lim Rev

1074

SO Status

1061

1

Limit

1073

SO Vel Lim Fwd

SO Vel Lim Rev

1074

Mode

1060 4

Scale Invert

SO Cong

0

1

÷

ReCap

Marker Pulse

Home DI

Rising

Edge

0

Home DI

SO Cong

1060

1

0

'

Overview VarCtrl PFC Vector Overview PRef Move Prof Ind 2 VelRefCAM Ld Obs Cur IPM MOP Logic

Metering DroopCtrl CurPwrLmt Freq Overview PRef2 Roll Psn VRef Vect Friction Comp Proc 1 22Series IO Digital Invert

PLL DBC CurrCtrl CBI Metering PReg Spindle Ref Move Trq RefCAM Proc 2 22Series IO Digital Motor I2T

PwrLoss VoltRefGen LscCtrlCfg Fdbk Psn PLL VRef Overview VReg Vect Trq Ref AntiSway 11-Series IO Digital High Speed Wizard

LscData VoltCtrl DriveDerating Homing Psn CAM VRef Sel Trq Overview Trq Filt Oil Well 1 22-Series IO Analog

CurRefGen DCBusObs PRef1 Prof Ind 1 VRef All Trq Ref Sel Cur IM SPM Oil Well 2 22-Series IO Analog Spindle

Loading...

Loading...