Rockwell Automation Publication DRIVES-AT005D-EN-P - May 2022 41

Chapter 4 Non-regenerative Bus Supply Configuration

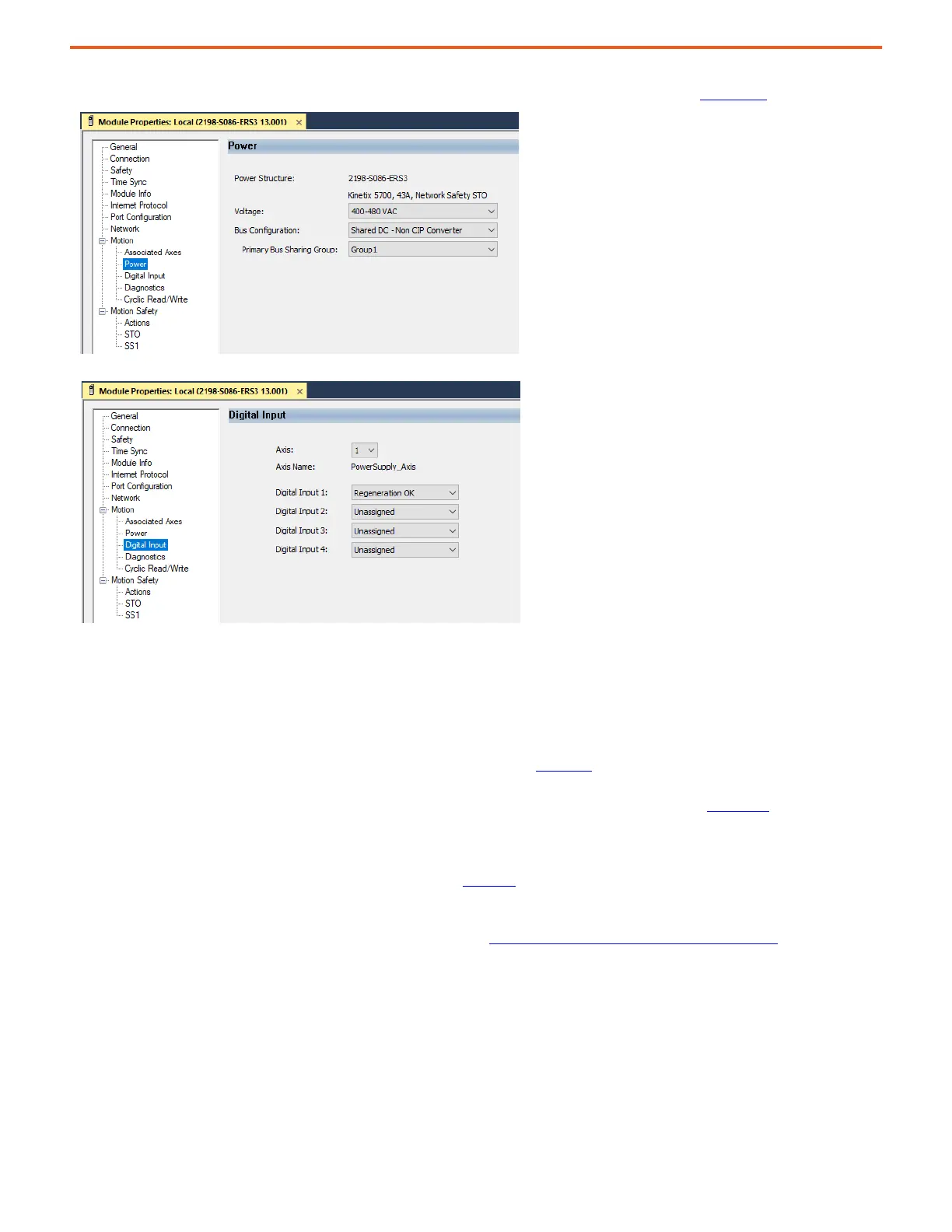

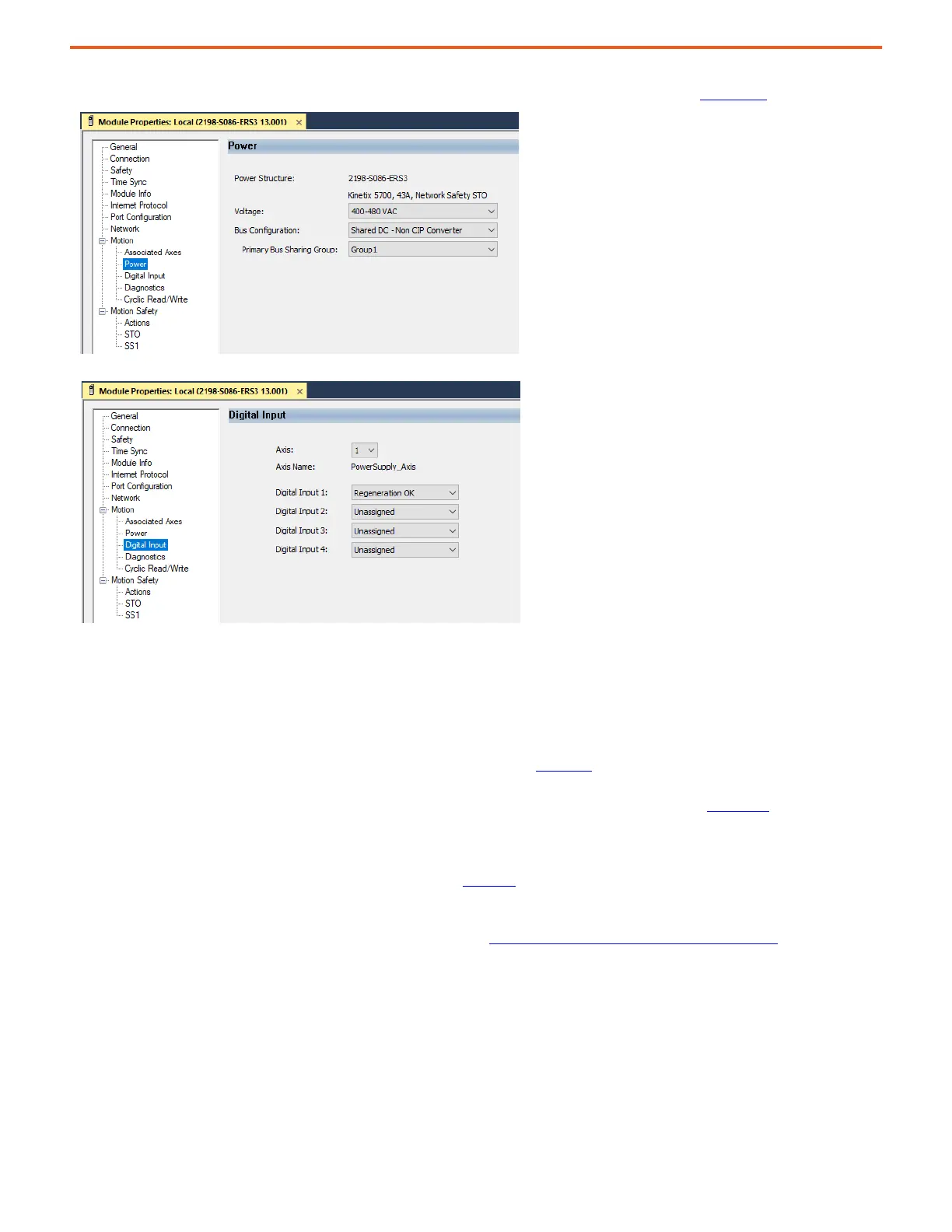

The following screen captures show the settings required for 'Shared DC - non-CIP Converter' bus configuration and 'Regeneration OK' digital input

within the Logix Designer application. For more details, see the Kinetix 5700 Servo Drives User Manual, publication 2198-UM002.

Paralleling PowerFlex 755TM Non-regenerative Modules

• The PowerFlex 755TM non-regenerative supply is available in two rating sizes: single density (1X) and dual density (2X). By paralleling

additional single- and/or dual-density modules, it’s possible to increase the rating of the overall non-regenerative bus supply.

• Parallel configurations are built-up from separate enclosures and 20-750-MN… single-density (1X) and dual-density (2X) roll-in modules. See

the PowerFlex 755TM IP00 Open Type Kits technical data manual, publication 750-TD101

, for more information.

• There are many possible combinations of paralleling single- and dual-density roll-in modules into a complete non-regenerative bus supply

converter. The ratings and specifications for single modules and various parallel configurations are shown in Appendix A

. Use these tables to

see the derated overall ratings. Use these tables to obtain the derated overall ratings for parallel combinations.

• Up to six single- and/or dual-density modules can be paralleled to configure a fully coordinated bus supply system for power ratings up to

4000 kW and 6000 Hp. Coordinated module operation requires that each parallel module is interconnected with the signal interconnection

harness. See PowerFlex 755TM IP00 Open Type Kits, publication 750-IN101

, for more information on parallel configurations.

• There are practical limitations to the current carrying capacity of the system bus bars and other components. Perform calculations for the

total bus supply rated DC current and make sure that the system requirements do not exceed the PowerFlex 755TM common DC bus system

bus bar rating (standard = 3000 A DC, option -P46 = 4700 A DC). See PowerFlex 755TM System DC Bus Ratings on page 99

for more

information about PowerFlex 755TM DC bus bar ratings. If the calculated total DC rated amps exceed these ratings, special design

considerations are required to make sure that the AC and DC bus bar systems are sized to handle the expected AC and DC currents. Back-to-

back or center-fed enclosure lineups may be used to satisfy these requirements. See the associated PowerFlex 755T technical data and

installation manuals for more information. Third-party enclosures with suitably rated AC and DC bus bars may also be employed to meet the

AC and DC current requirements of this example system.

• If you have an application that requires paralleling of more than six PowerFlex 755TM non-regenerative bus supply modules, contact

Rockwell Automation.

Loading...

Loading...