6.1

6.6.

73FPD-2010

6 Troubleshooting

6.1Troubleshooting

This chapter covers causes of and countermeasures against errors frequently encountered when

using the FPD.

Errors which are attributable to the gas chromatograph main unit are covered in “Troubleshooting” in the

instruction manual of the gas chromatograph.

If a trouble cannot be cleared by the counter measure given here after, or if troubles other than outlined in

this chapter occurs, contact Shimadzu office or agent which is nearest to you.

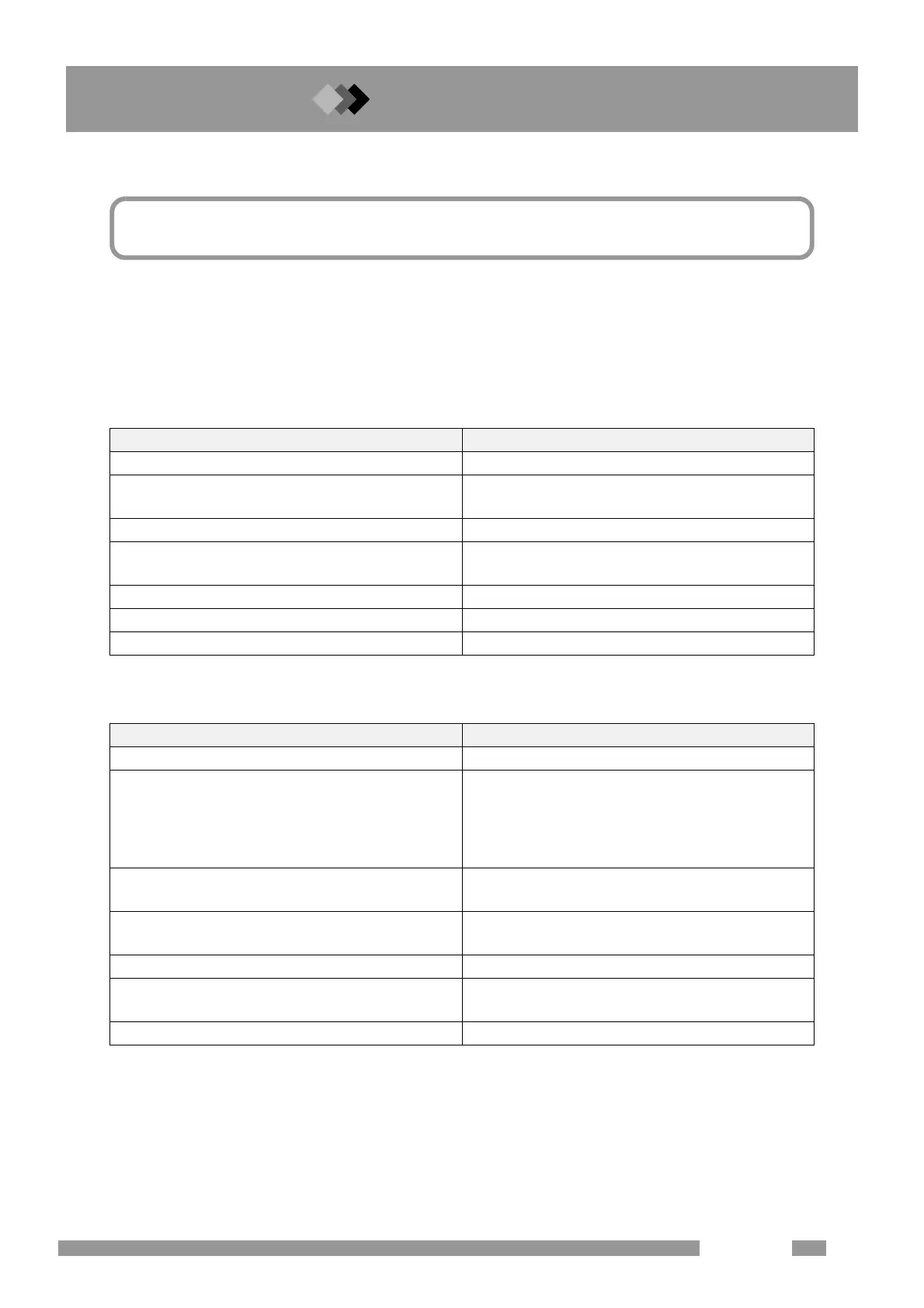

1.

The

Cause Countermeasures

The column is not connected. Connect the column.

Hydrogen gas is not supplied, or the flow rate is inappro-

priate.

Supply hydrogen gas or correct the flow rate.

Air is not supplied, or the flow rate is inappropriate. Supply air or correct the flow

The igniter filament has blown off. Replace the igniter filament.

(Contact your local Shimadzu techincal office.)

The detector temperature is too low. Increase the detector temperature.

Shield ring position is inadequate. Set the shield ring to adequate height.

APC is failed. Contact your local Shimadzu techincal office

flame is not ignited. The flame goes off.

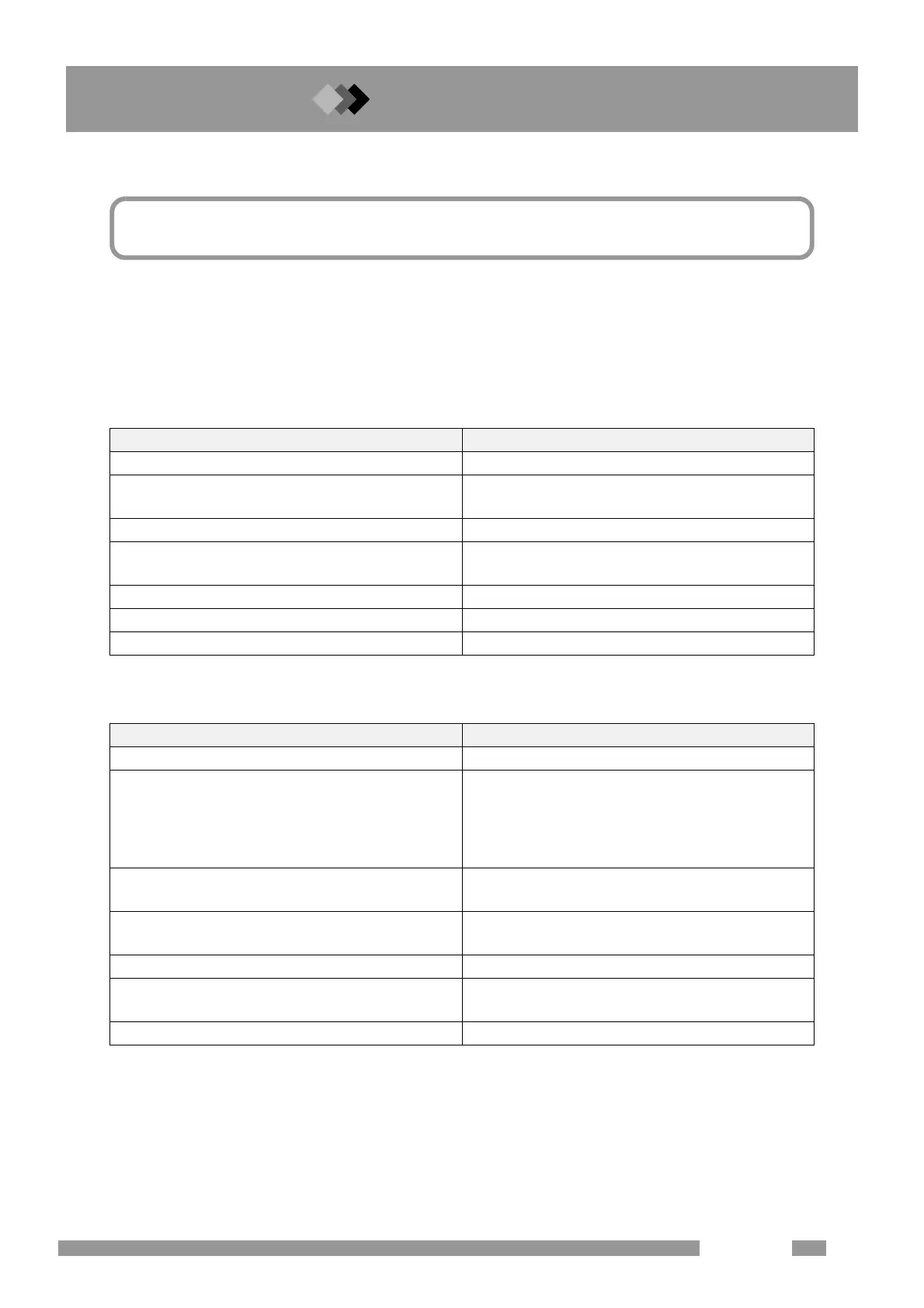

2.

Abnormal baseline

■ Significant noise occurs in the baseline.

Cause Countermeasures

The electrical connector is not securely connected. Check the connector and connect securely.

There is a large quantity of impurities in the carrier and

detector gases.

the Filter (Molecular Sieve Fillter, Gas Fil•Replace -

ter of Oxygen Trap).

the tubes and joints.•Replace

the gas container, changing to a gas of

higher purity.

•Replace

Gas leakage Check for gas leakage and correct any piping joints

from which gas is leaking.

Stray light Determine from where the light is leaking by using a

dark film and stop the stray.

Shield ring position is inadequate. Set the shield ring to appropriate height.

Water drops are produced around the exhaust ventila-

tion.

Purge the exhaust ventilation sufficiently to eliminate

the adhered water drops.

APC is failed. Contact your local Shimadzu techincal office

Loading...

Loading...