•

"S

ender and receiver alignment", page 41

•

"Alignment with the QuickFix bracket", page 43

5.3.1 Mounting the QuickFix bracket

Overview

2 Q

uickFix brackets are used to mount the sender and receiver.

The QuickFix bracket consists of 2 parts, which are pushed into each other. The two

individual parts are connected with an M5 screw and the housing (sender or receiver) is

clamped with form-fit clamping.

The two mounting surfaces for the brackets of the sender or receiver must be parallel

and lie in the same plane.

Important information

NOTE

T

he following should be considered when mounting the QuickFix bracket:

•

Select the appropriate length of the M5 screw to prevent any risk of injury from an

overrun.

•

When selecting the screw length, observe the wall thickness and the depth of the

countersunk screw of the QuickFix bracket, see figure 29, page 59

NOTE

T

he QuickFix bracket has cable routing. Depending on the installation, the cable routing

can make mounting easier.

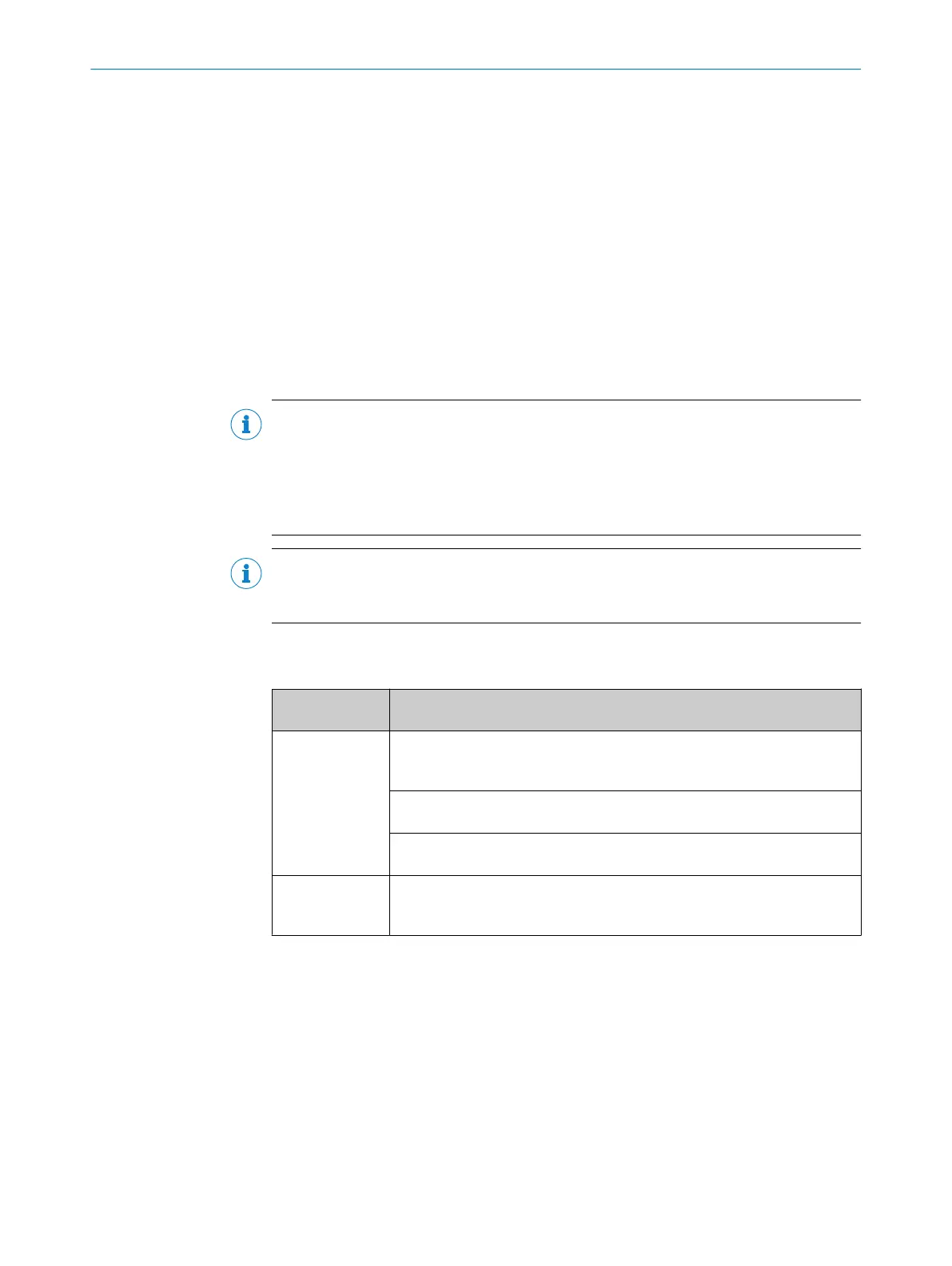

Mount QuickFix bracket on a machine or profile frame

T

able 4: Side and rear mounting with the QuickFix bracket

Mounting

me

thod

Description

On the side Fasten the M5 screw to the machine or profile frame through the QuickFix

br

acket. A screw nut or threaded hole is required on the machine or profile

frame (1).

Fasten the M5 screw to the QuickFix bracket through the machine or profile

fr

ame. A screw nut is required for each QuickFix bracket (2).

Fasten the M5 screw to the profile frame through the QuickFix bracket. A

slidin

g nut is required on the profile frame (3).

On the back Fasten the M5 screw to the machine or profile frame through the QuickFix

br

acket. A screw nut or threaded hole is required on the machine or profile

frame (4).

Tightening torque: 5Nm…6Nm

5 MOUNTING

36

O P E R A T I N G I N S T R U C T I O N S | deTec4 Core Vibes 8024467/1GWF/2022-11-11 | SICK

Subject to change without notice

Loading...

Loading...