Product description

30 © SICK AG · Germany · All rights reserved · Subject to change without notice 8013796/ZM63/2017-05-09

Operating Instructions

LMS5xx Laser Measurement Sensors

Chapter 3

3.7.3 Minimum object size

To reliably detect an object, a laser beam must be fully incident on it once. If the beam is

partially incident, less energy could be reflected by the object (see Fig. 11 on page 27).

An object is only reliably fully seen if it is at least as large as the measured point spacing

plus the beam diameter.

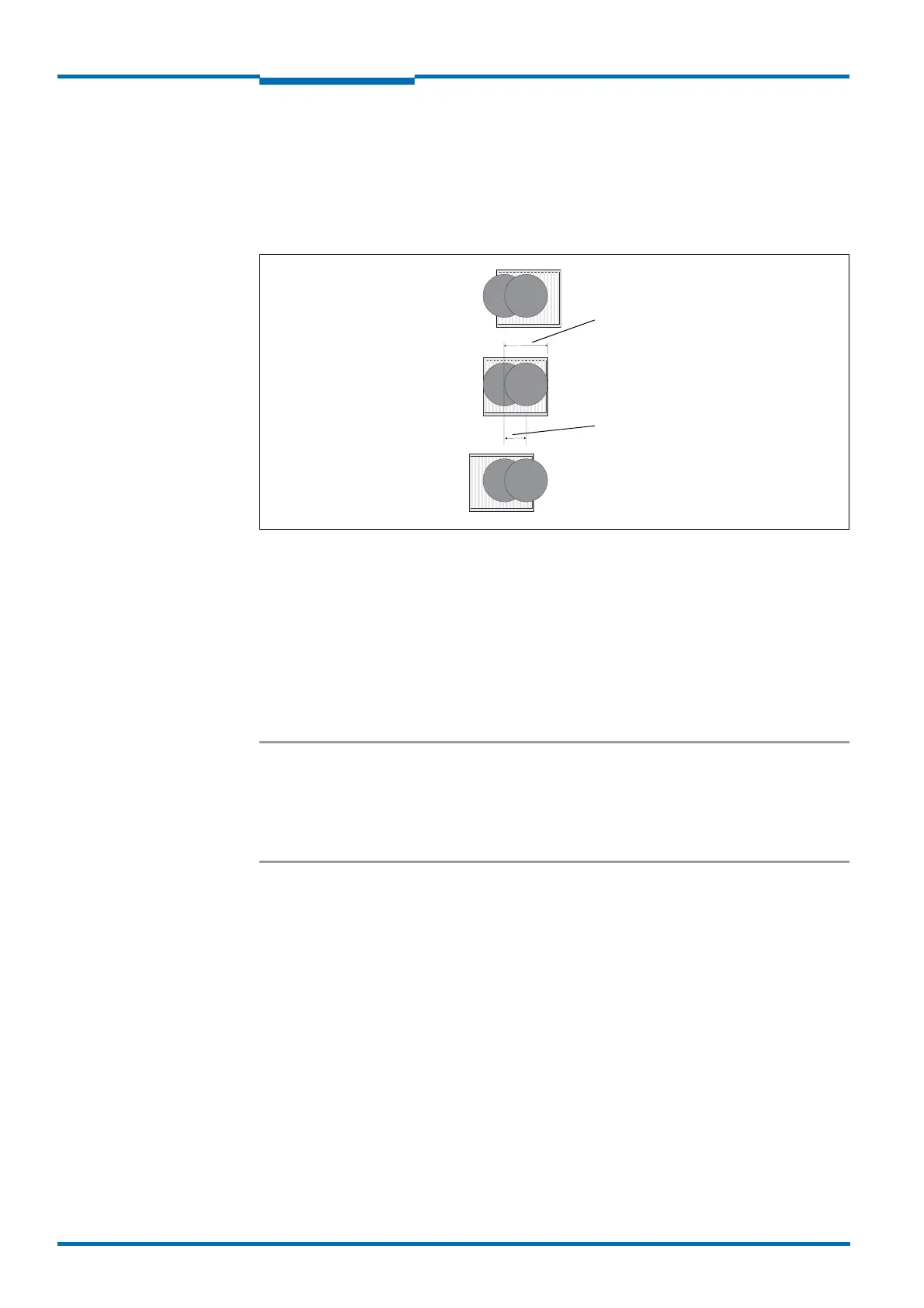

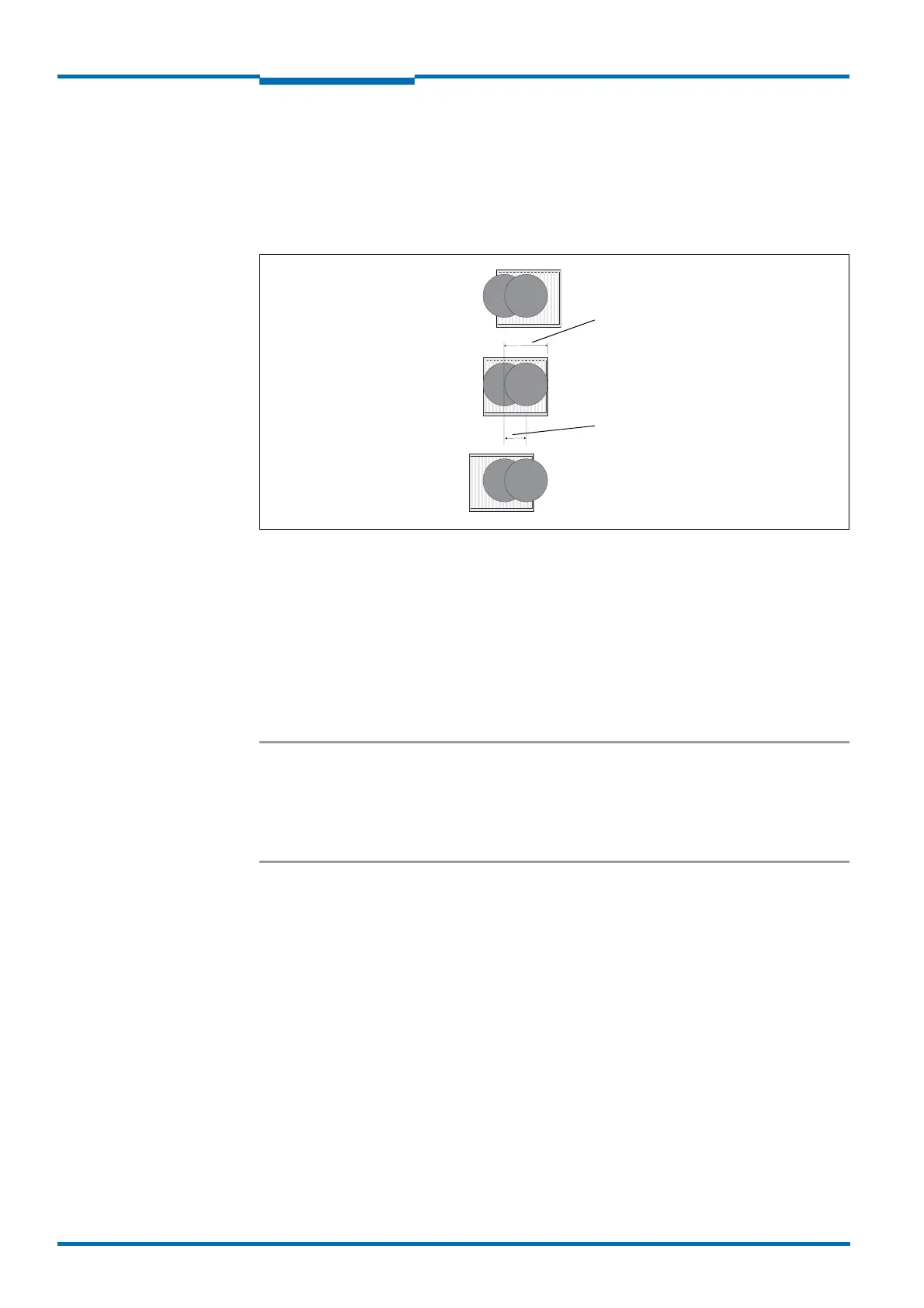

Fig. 16: Minimum object size for detection

In the example in Fig. 16, the beam is fully incident on the object at least once during each

scan. It will therefore be reliably detected if it has the necessary remission.

How to calculate the minimum object size:

Beam diameter + distance between the measured points = minimum object size

For beam diameter and measured point spacing as a function of the distance from the

LMS5xx see the diagram in Fig. 15 on page 29.

Important In particular on the usage of the LMS5xx for measured value output, it is necessary for a

reliable measurement that the beam is incident on the object several times. The example

shows the minimum size of an object. For a reliable measurement it is important that the

beam is incident on the object several times. Therefore an object should be either larger

than the minimum object size or the LMS5xx as well as the object should not move.

3.7.4 Contamination measurement

The LMS5xx has a front screen for protection. This front screen can become contaminated.

The laser beam radiation emitted and received is reduced by the contamination. As a result

scanned objects are perceived with a lower remission than they actually have, or no longer

measured at all from a certain level of contamination. The LMS5xx is equipped with 6 dedi-

cated contamination sensors. Depending on the contamination strategy chosen, a selected

number of these sensors will be taken into account. The 6 contamination sensors are

divided in 2 groups (3 + 3).

For this reason the contamination is monitored continuously by a dedicated system while

the device is in operation. For different levels of contamination, first a contamination

warning is output; if the screen is not cleaned and the contamination becomes worse, a

contamination error is output and the LMS5xx stops taking measurements.

Depending on the application in which the LMS5xx is used, you can choose between various

strategies for the contamination measurement.

Scan 1

Scan 2

Scan 3

Beam diameter

Distance between measured points

Loading...

Loading...