Technical Appendix

6.2 PLC user interface signals

6-116

SINUMERIK 802C

6FC5 597–3AA20–0BP2 (01.02)

390x1001

(axis)

390x1002 Lubrica-

(axis)

tion pulse

390x1003

(axis)

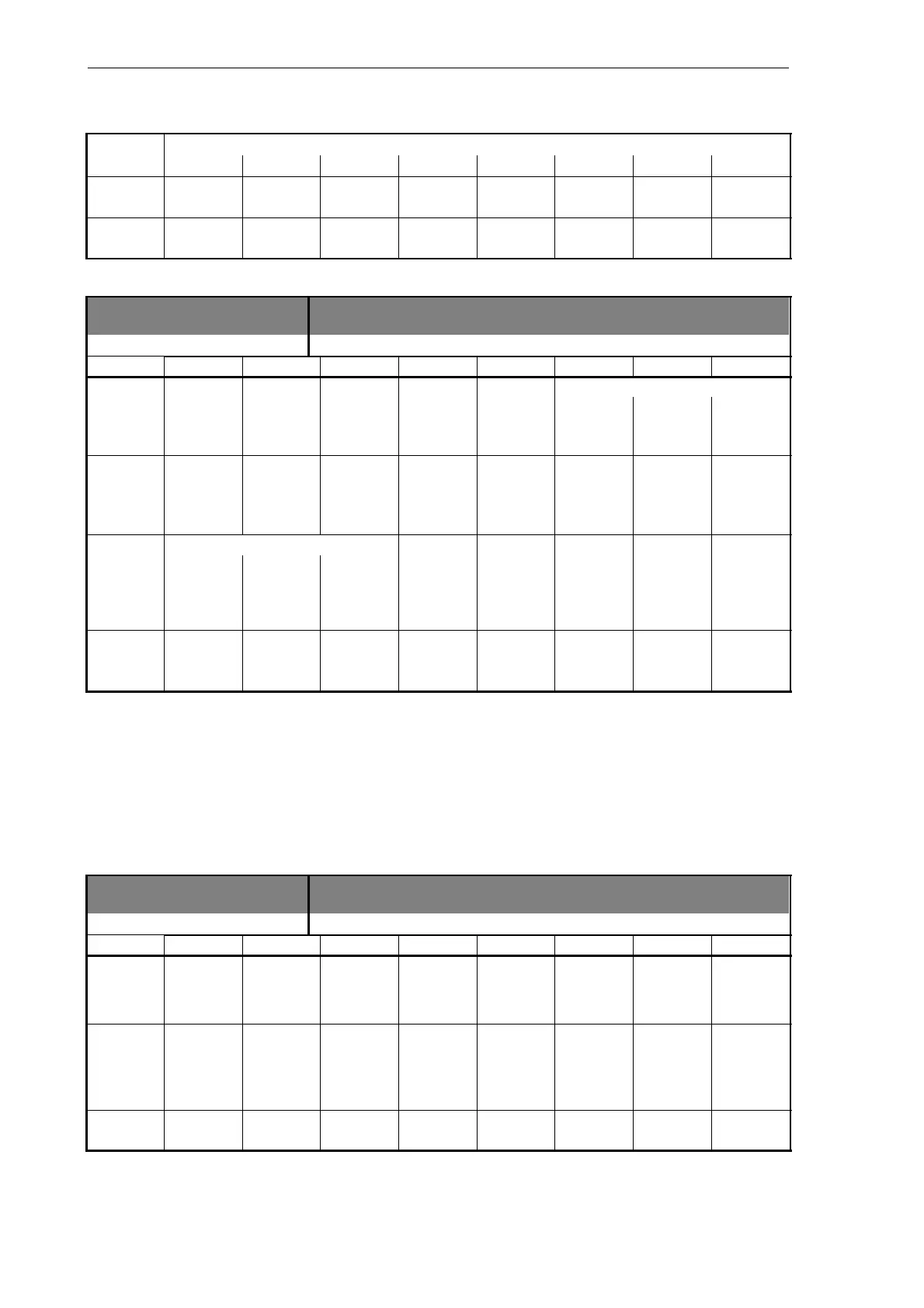

Signals from spindle

3903 Signals from spindle [r]

Data block

Interface NCK –––––> PLC

Byte Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Set gear stage

39032000 Change

gear

(spindle)

C B A

Actual di-

rection

Spindle Set Set Speed

39032001 of rotation within set speed speed limit

(spindle)

CW range increased limited exceeded

Active spindle mode Tapping

39032002 Control Recipro-

cating

Position-

ing

without

compen-

sating

(spindle)

mode mode mode chuck

39032003

(spindle)

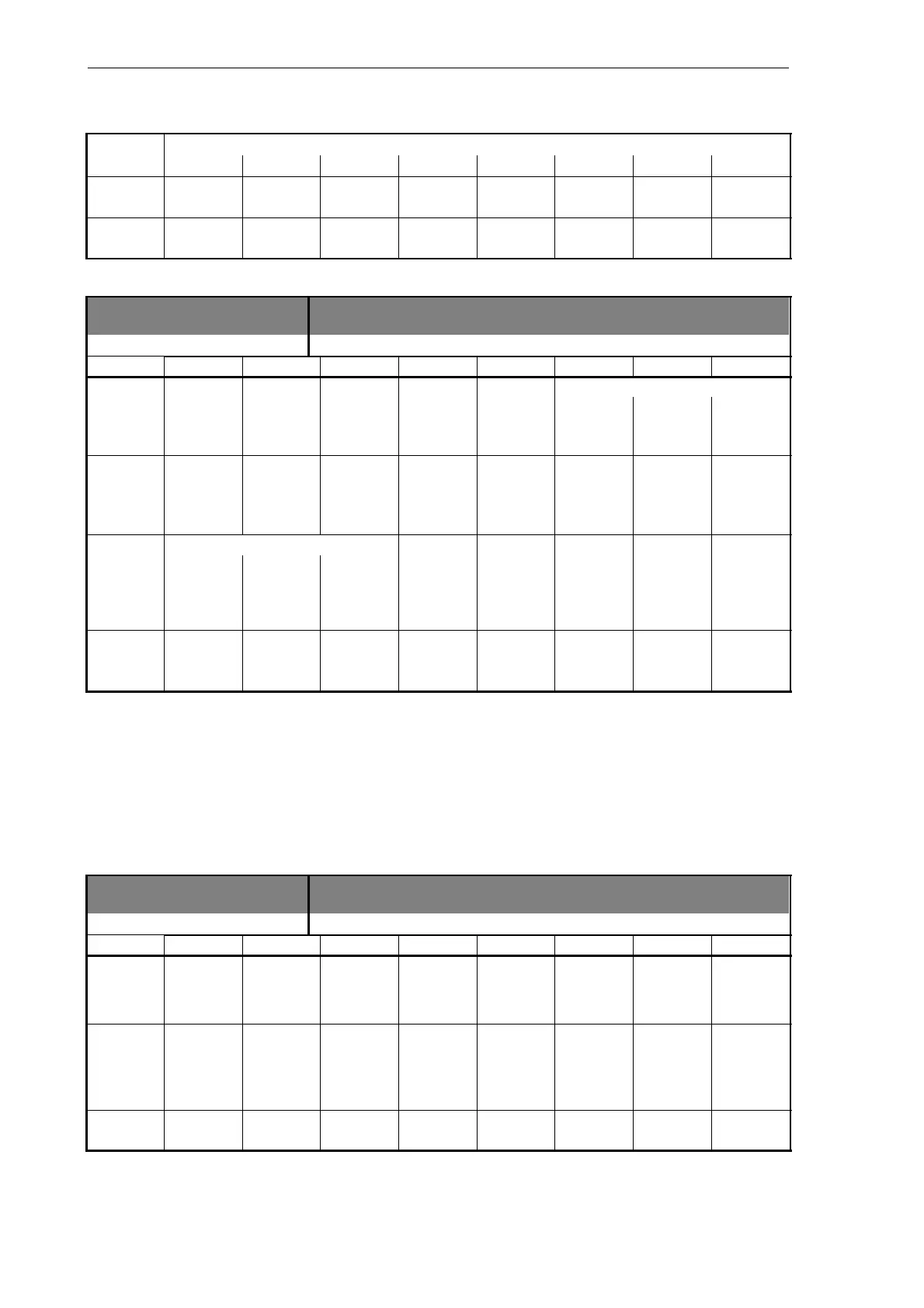

6.2.6 Signals from/to MMC

Program control signals from MMC (retentive area)

(see also signals to channel V32000000)

1700 MMC signals [r]

Data block

Interface MMC –––––> PLC

DBB Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Dry run

17000000 feed M01

(MMC –––>

PLC)

selected selected

Program Feed

17000001

test

selected

override

for rapid

(MMC ––>

PLC)

traverse

selected

Select

17000002 Skip

Loading...

Loading...