24

• All safety requirements must be met.

• A professional instructor is required in the whole hoisting process.

• All the used slings must have the load-bearing capacity of at least 10t.

• The crane should have sufficient arm length and radius of gyration.

• All the connection point must be firmly connected.

• The length of the slings can be adjusted appropriately according to on-site

conditions.

• Transport the inverter in a level, smooth, and steady way.

• Transport the inverter by connecting the four top corner fittings.

• Some accessories may be required to ensure the safety during hoisting.

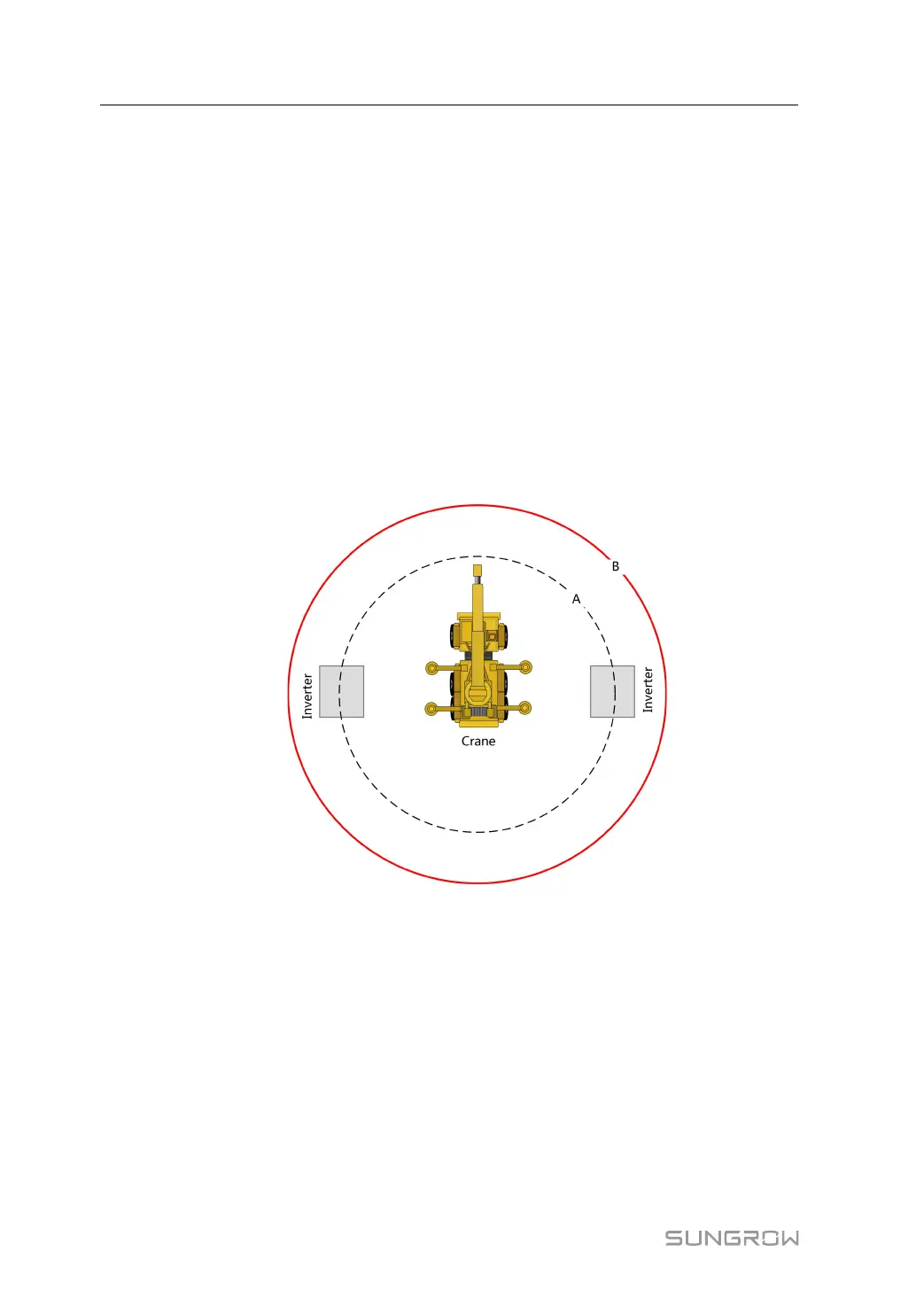

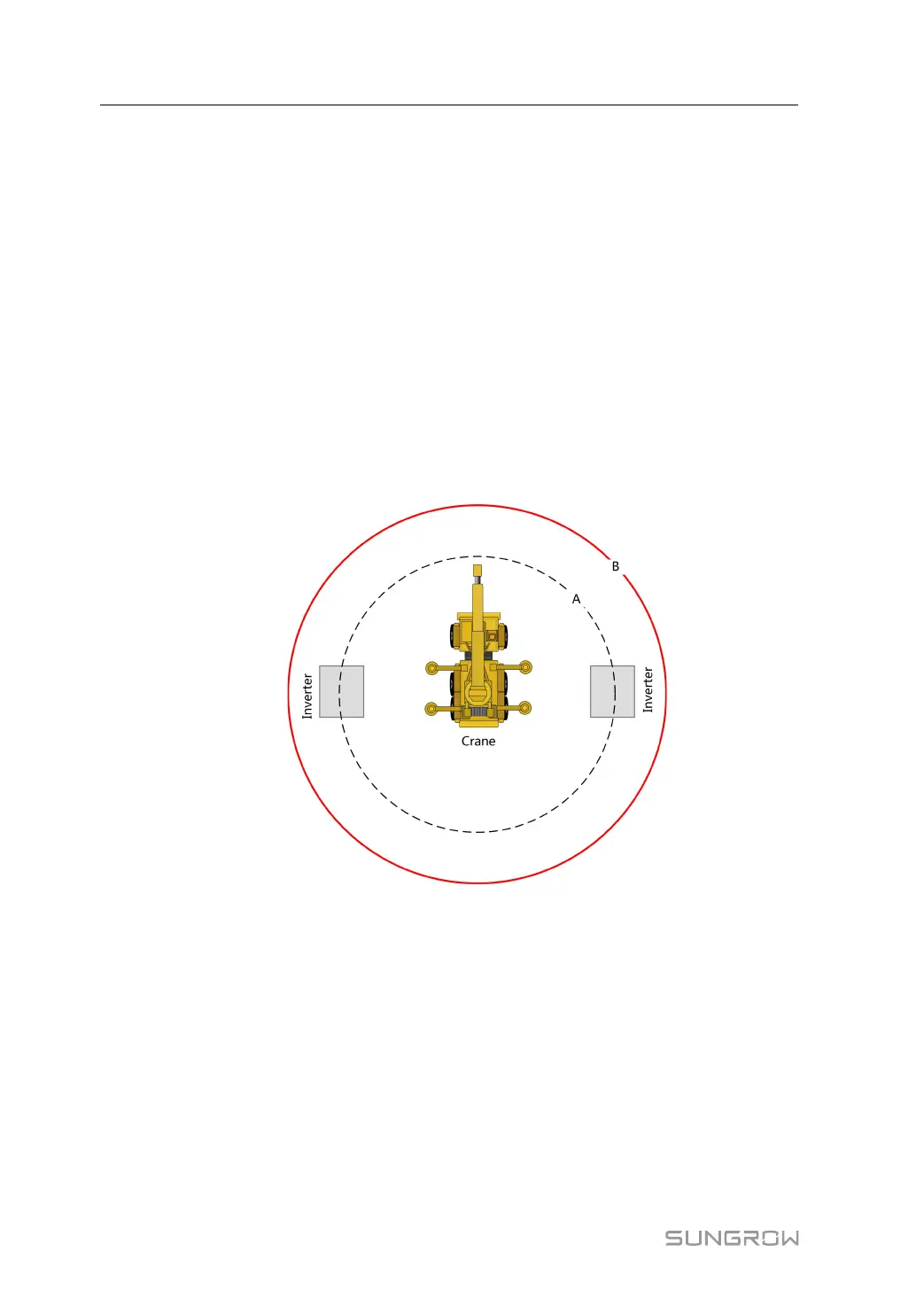

The following figure illustrates the hoisting operations. Circle A indicates the work areas

of the crane. Anybody standing inside the circle B is prohibited for safety considerations.

5.2.2 Hoisting

During the whole hoisting process, observe the following rules:

• Hoist the inverter in a vertical manner. Do not drag or drop the inverter on any

surface.

• When the inverter has been hoisted for about 300mm away from the ground, stop to

check if all the connections are still firm. After confirmation, continue hoisting the

inverter.

• When transported to the final location, the inverter should be put down slowly and

steadily.

• The final location should be firm, level, and well-drained. The inverter is supported by

four bottom fittings on the ground.

5 Mechanical Installation System Manual

Loading...

Loading...