TM 11-6625-2735-14-1

Troubleshooting the L.V. Power Supplies. Incorrect

operation of all circuits often indicates trouble in the

power supply. Check first for correct voltage of the

individual supplies. A defective component elsewhere in

the instrument can appear as a power-supply trouble and

may also affect the operation of other circuits. Table 4-2

lists the tolerances of the power supplies in this instru-

ment. Check or repair the power supplies in the sequence

specified in Table 4-2. These voltages are measured

between the power-supply test points and ground. If a

power-supply voltage is within the listed tolerance, the

supply can be assumed to be working correctly. If outside

the tolerance, the +50-volt supply may be misadjusted or

other supplies may by operating incorrectly. Use the

procedure given in TB 11-6625-2735-35-1 to adjust the

+50-volt supply if adjustment is necessary.

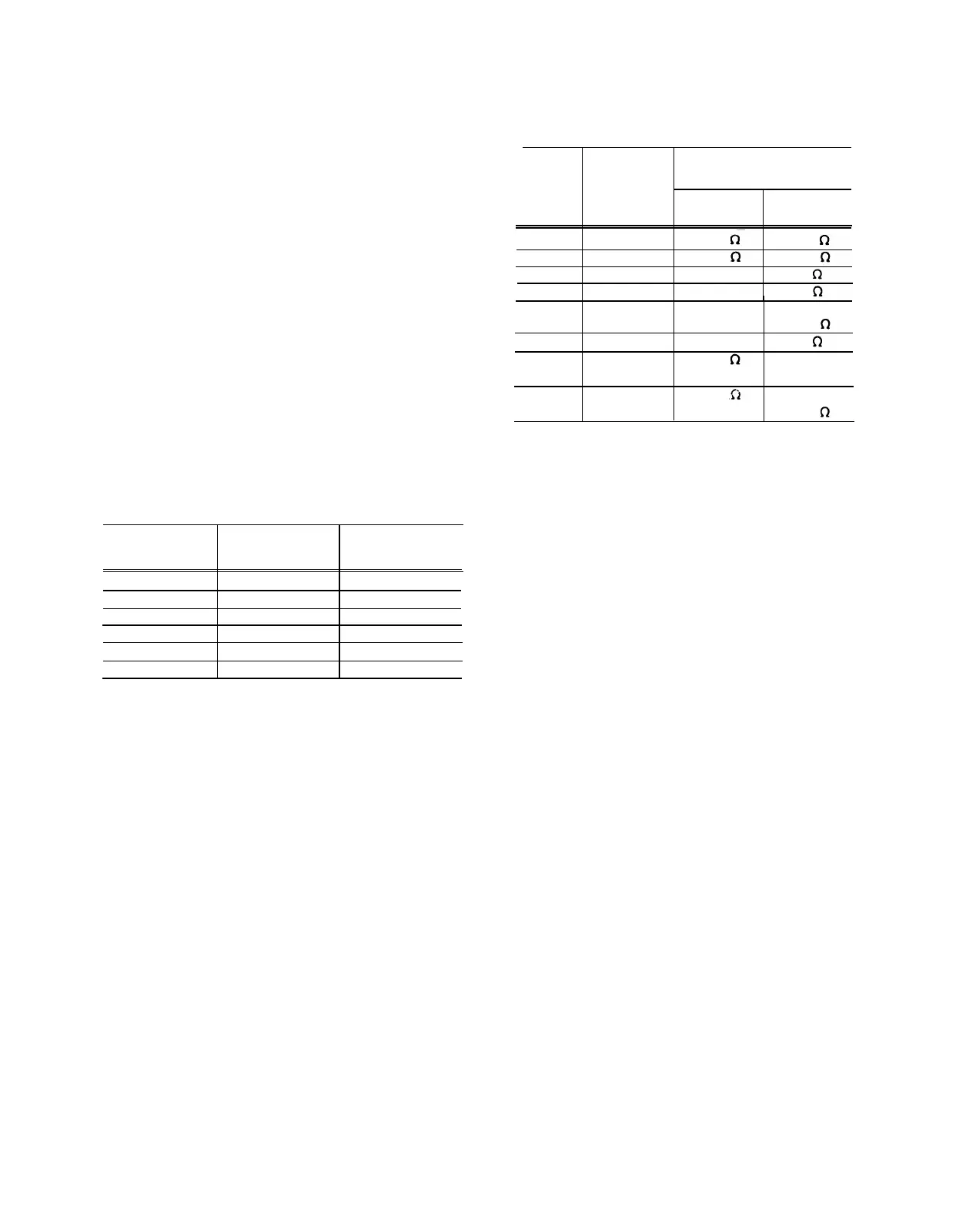

TABLE 4-3

Power Supply Resistance Check

1

Typical Resistance

To Ground’

Ohmmeter + Lead

– Lead

Supply

Scale

2

At Supply

At Supply

+110V

20 K

11 k

9.3 k

+50 V

20 K

2.7 k

2.7 k

+15V

2K

63

63

4-5

V

2K 46

46

—15 V

2K

480

- - - - -

20 K

- - - - -

10 k

-8 V

2 K

32 32

UNREG

20 K

14 k

- - - - -

+50 V

2K

- - - - -

500

+105/

20 K

12 k

- - - - -

160 V

2K

-----

1 k

TABLE 4-2

Power Supply Tolerance and Ripple

Typical Ripple

Power Supply

Tolerance

(peak-to-peak)

+50V

0.5% (250 mV)

2 mV

+110V

3% (3.3 V)

1 V

+15V

1.5% (225 mV)

2 mV

+5V

1 .5% (75 mV)

2 mV

-15V

1.5% (225 mV)

2 mV

-8V

1.5% (120 mV)

2 mV

If any of the supplies are shorted to ground, repair them

until normal resistance readings are obtained. Connect

the instrument to the correct power source and check the

supplies for proper voltages listed in Table 4-2. If two or

more of the individual supplies have incorrect voltages,

repair them in the order listed in Table 4-2.

The +50 volt supply is the reference for all other

supplies and must be repaired first. The +15 volt supply

and the +5 volt supply should be working properly before

repair on the –8 volt supply or the –15 volt supply is

attempted.

Connect the 475 to a variable autotransformer. Then,

check each power supply for correct ripple with a test

When repairing a power supply in the 475 the following

oscilloscope, while varying the autotransformer

throughout the regulating range of this instrument (see

Information may be helpful. The +50-volt supply is used as

an example to identify component functions.

rear panel regulating range selector cover for regulating

range). Table 4-2 lists the typical ripple of the power

supplies in this instrument. Measure the ripple between

the power supply test points and ground.

1. Check for proper voltage and ripple from the diode

bridge rectifier (CR1412 in the +50-volt supply; check at

collector of the series regulator for any supply).

A malfunction in the power supply can be caused by

one or more supplies being shorted to ground. Check the

resistance of the individual supplies to ground against the

1

Instrument power cord should be removed from power source.

typical resistances Iisted in Table 4-3. Be sure the instru-

ment is not connected to a power source when making

2

Readings taken with a digital ohmmeter (see item 3 under

Troubleshooting Equipment in this section).

these measurements to prevent error in resistance

readings and to prevent possible meter damage.

3

Readings are normal if within 50% of listed valve.

4-15

Loading...

Loading...