necessary.(seeanAuthorizedToro

ServiceDistributor)

Every400hours/Yearly(whichever

comesrst)—Inspectthepump

checkvalvesandreplaceifnecessary.

(seeanAuthorizedToroService

Distributor)

Note:Thefollowingmachinecomponentsare

consideredpartssubjecttoconsumptionthroughuse

unlessfounddefectiveandarenotcoveredbythe

Warrantyassociatedwiththismachine.

HaveanAuthorizedToroServiceDistributorcheck

followinginternalpumpcomponentsfordamage:

•Pumpdiaphragm

•Pressuredampenerbladder

•Pumpcheckvalvesassemblies

Replaceanycomponentsifnecessary.

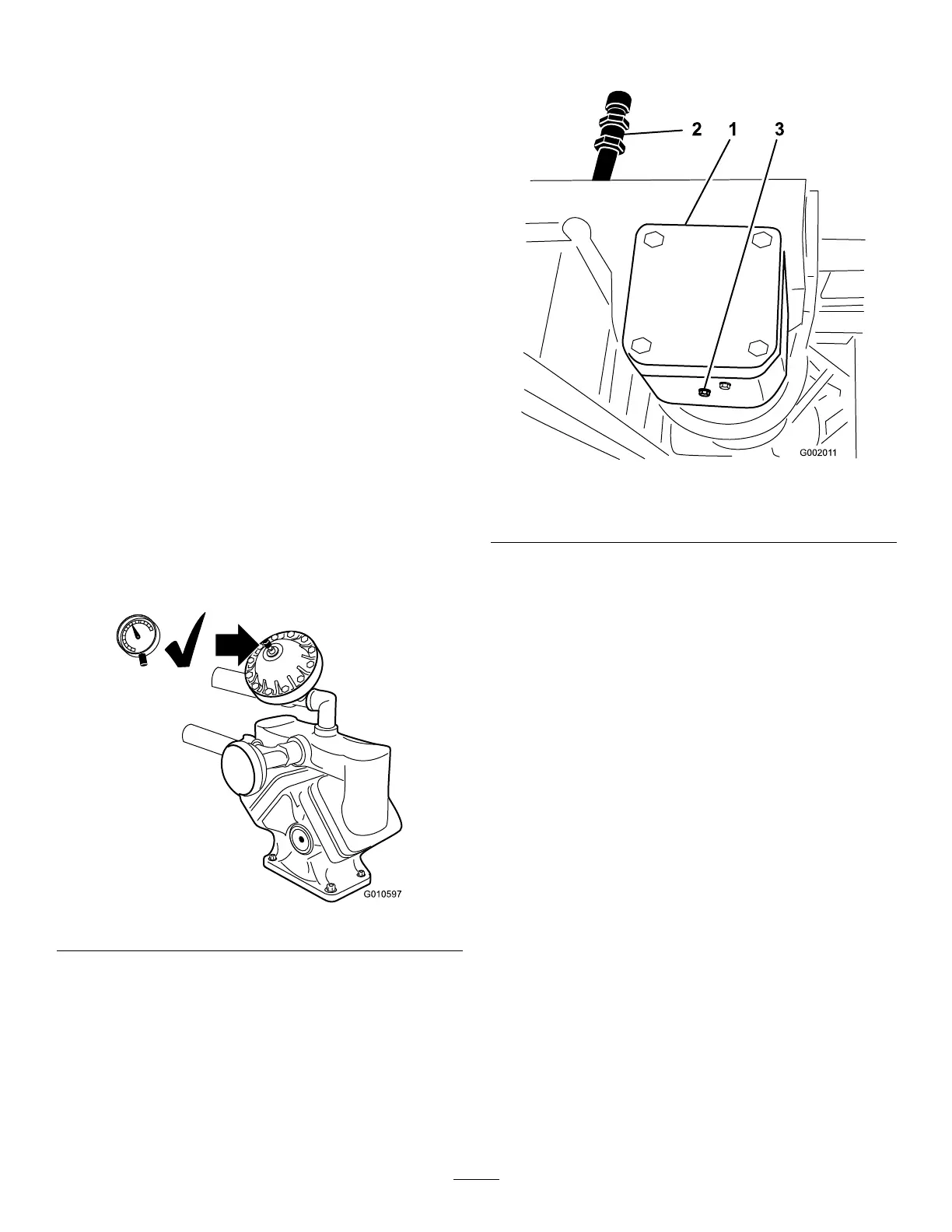

AdjustingtheAirPressureinDampener

Theairpressureinthedampeneronthepumpissetat

15psi(1bar)bythemanufacturer.Therecommended

pressureinthedampeneris1/3ofthesprayingpressure.

Ifusingaspraypressuregreaterthan45psi(3.1bar)

adjustthedampeneraccordingly.

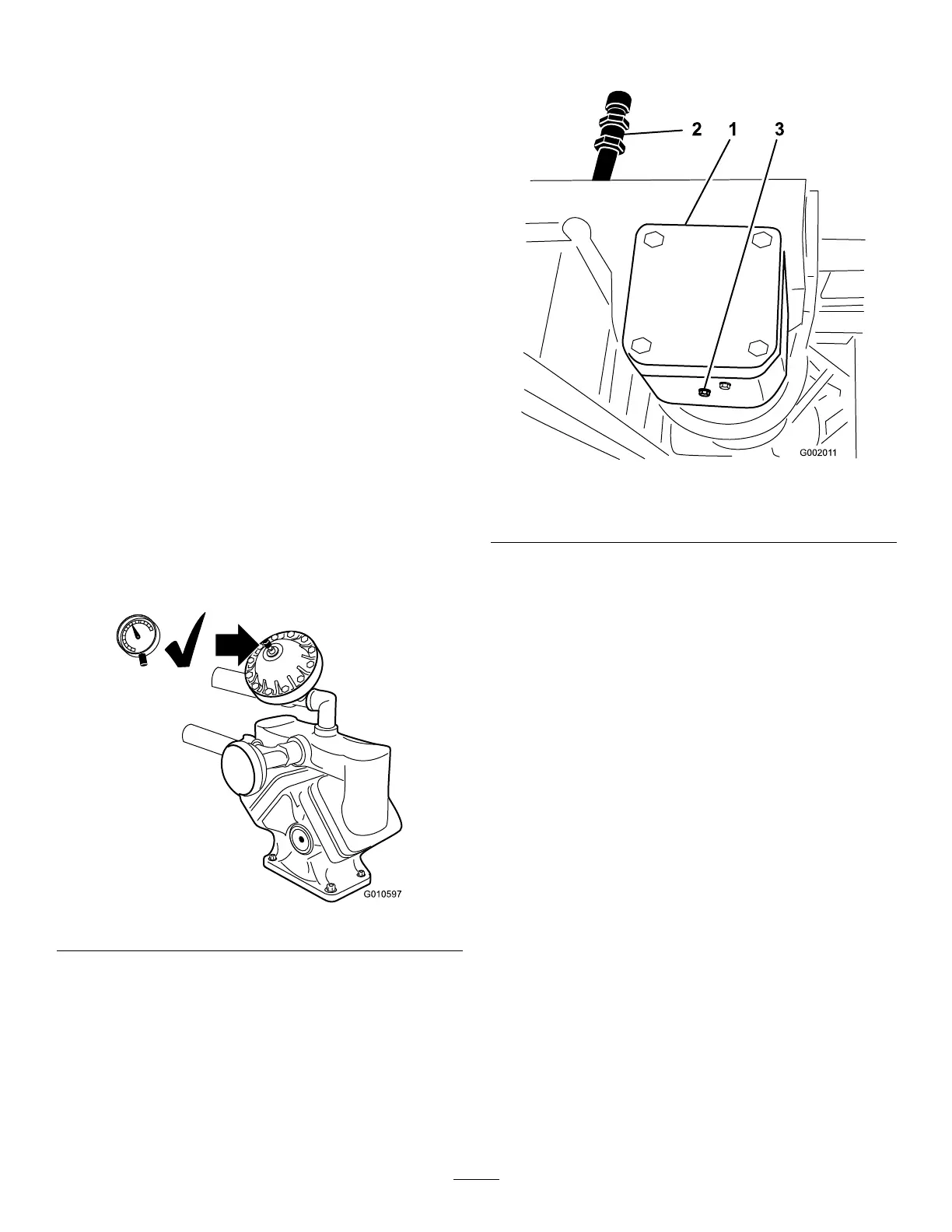

Figure69

ChangingthePumpDriveGearbox

Fluid

ServiceInterval:Every400hours/Yearly(whichever

comesrst)

1.Positionthesprayeronalevelsurface,settheparking

brake,stopthepump,stoptheengine,andremove

theignitionkey.

2.Placeapanunderthedrainplugonthepumpdrive

gearbox(Figure70).

Figure70

1.Pumpdrivegearbox3.Drainplug

2.Filltube

3.Removethellpluganddrainplug(Figure70),

allowingtheoiltodrainintothepan.

4.Installandtightenthedrainplugwhentheuid

stopsdraining.

5.Addapproximately1quart(1L)ofMobilSHC634

SyntheticLubricanttothelltube.

Important:UseonlyMobilSHC634Synthetic

Lubricantorequivalentsyntheticuidinthe

gearbox.Non-syntheticoilsmaybreakdown

causingdamagetothepumpgearbox.

6.Installthellplug.

AdjustingtheBoomActuator

ServiceInterval:Every400hours—Checkboom

actuatorhydraulicoilforairbubbles.

1.Positionthesprayeronalevelsurface,lowerthe

boomsintothesprayposition.

2.Settheparkingbrake,stopthepump,stopthe

engine,andremovetheignitionkey

3.Attempttolifttheboombyapplyingamoderate

amountofpressure(justenoughtolifttheboom

manually)whileobservingtheactuatorrod.Ifthe

actuatorrodexhibitsmovementrefertobelow .

4.Repeattheprocedurefortheopposingboom.

56

Loading...

Loading...