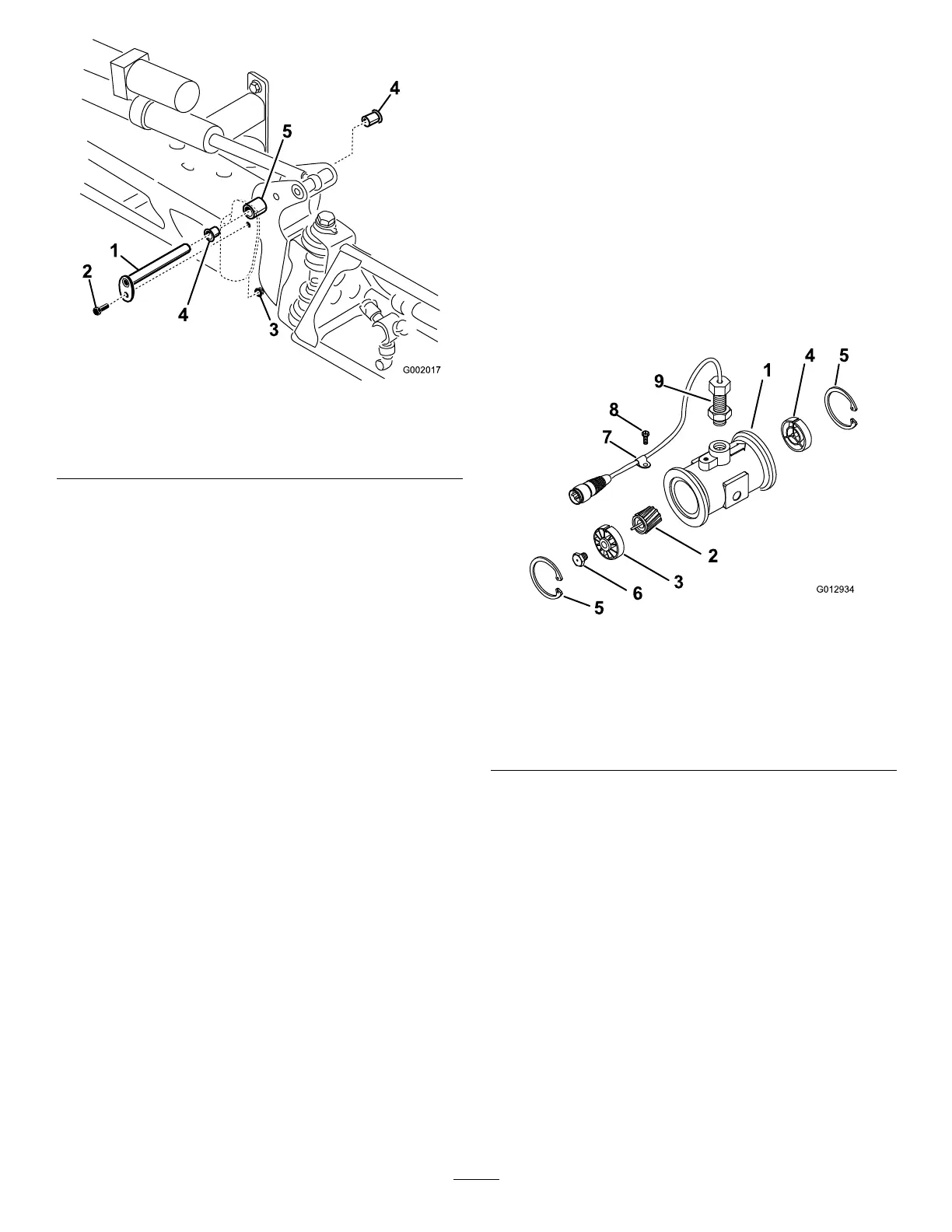

Figure72

1.Pivotpin4.Nylonbushing

2.Bolt5.Pivotbracket

3.Nut

4.Removetheboomandpivotbracketassemblyfrom

thecenterframetoaccessthenylonbushings.

5.Removeandinspectthenylonbushingsfromthe

frontandbacksidesofthepivotbracket(

Figure72).

Replaceanydamagedbushings.

6.Placeasmallamountofoilonthenylonbushings

andinstallthemintopivotbracket.

7.Installtheboomandpivotbracketassemblyintothe

centerframe,aligningtheopenings(

Figure72).

8.Installthepivotpinandsecureitwiththeboltand

nutremovedpreviously.

Repeattheprocedureforeachboom.

Cleaning

CleaningtheFlowmeter

ServiceInterval:Every200hours/Yearly(whichever

comesrst)(Moreoftenwhenusing

wettablepowders)

1.Thoroughlyrinseanddraintheentirespraying

system.

2.Removetheowmeterfromthesprayerandush

itwithcleanwater.

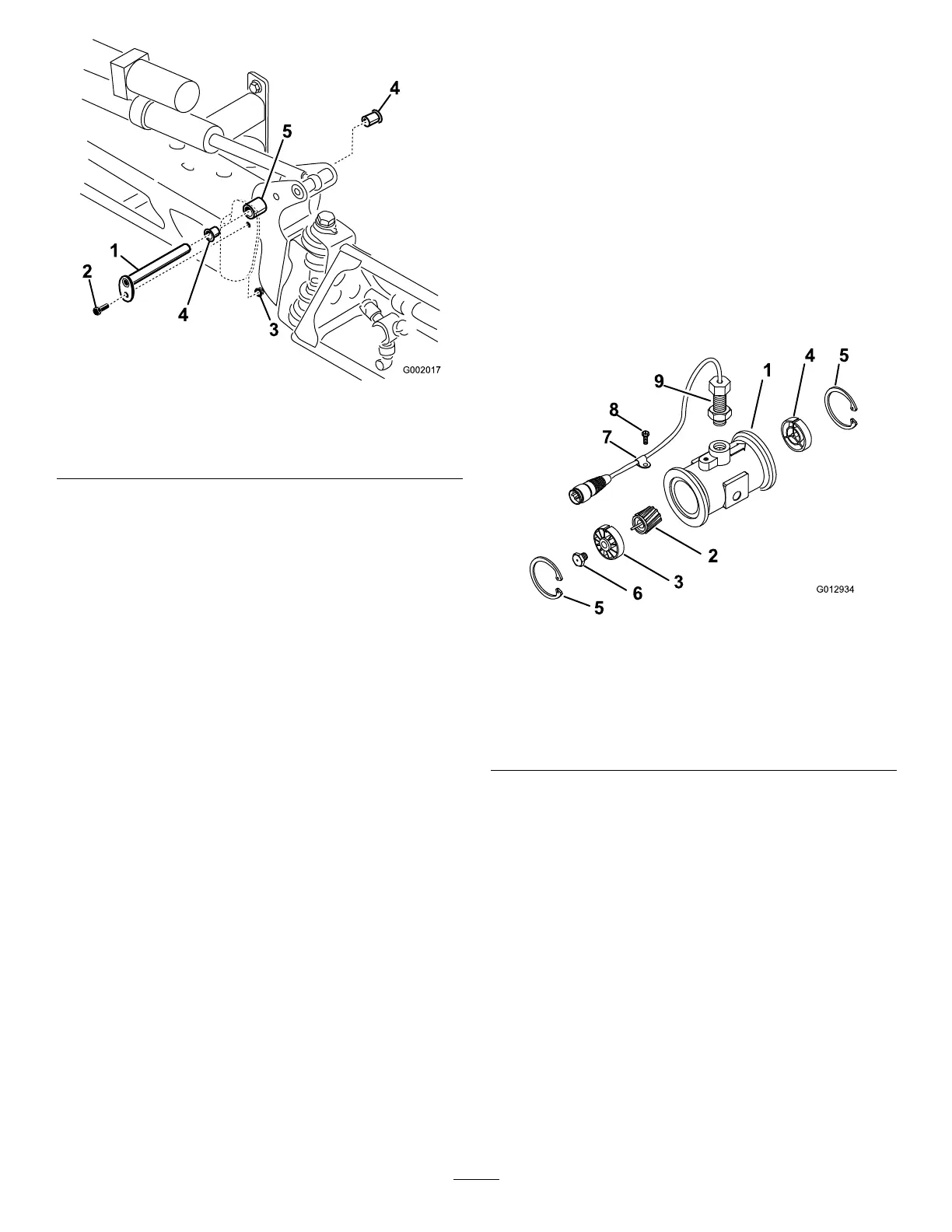

3.Removetheretainerringontheupstreamside

(

Figure73).

Figure73

1.Modiedangedbody

6.Turbinestudassembly

2.Rotor/magnetassembly7.Cableclamp

3.Hub/bearingassembly

8.Threadscrew

4.Hubassembly(with

keywayup)

9.Sensorassembly

5.Retainingring10.Flow-reducingsleeve

4.Cleantheturbineandtheturbinehubtoremove

metallingsandanywettablepowders.

5.Inspecttheturbinebladesforwear.

Note:Holdtheturbineinyourhandandspinit.

Itshouldspinfreelywithverylittledrag.Ifitdoes

not,replaceit.

6.Assembletheowmeter.

7.Usealowpressure(5psior50kPa)airjettoensure

thattheturbinespinsfreely.Ifitdoesnot,loosen

thehexstudonthebottomoftheturbinehubby

1/16ofaturnuntiltheturbinespinsfreely.

CleaningtheSuctionStrainer

ServiceInterval:Beforeeachuseordaily(moreoften

whenusingwetablepowders)

58

Loading...

Loading...