LubricatingtheCaster-Wheel

Hubs

ServiceInterval:Yearly

1.Shutofftheengine,waitforallmovingpartstostop,

engagetheparkingbrake,andremovethekey.

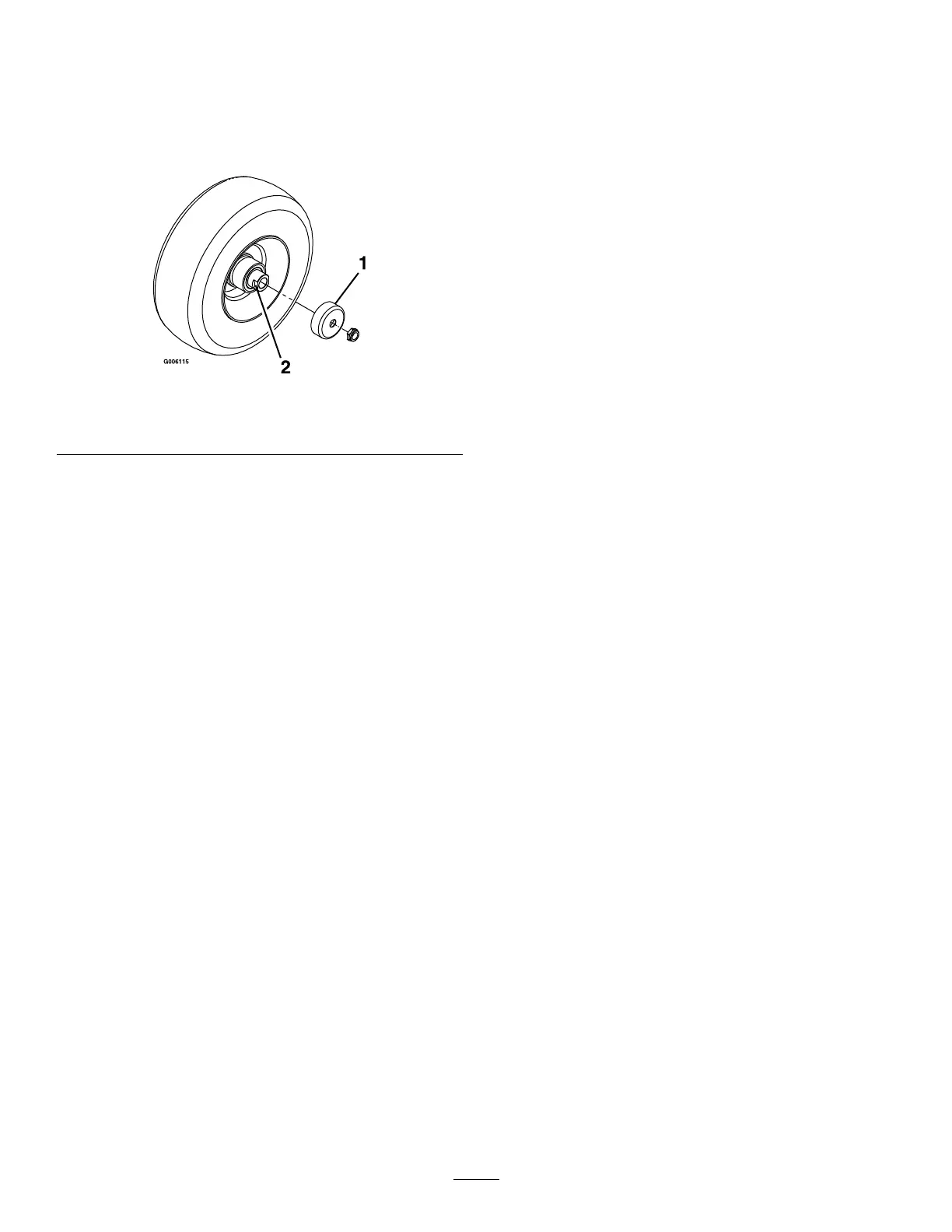

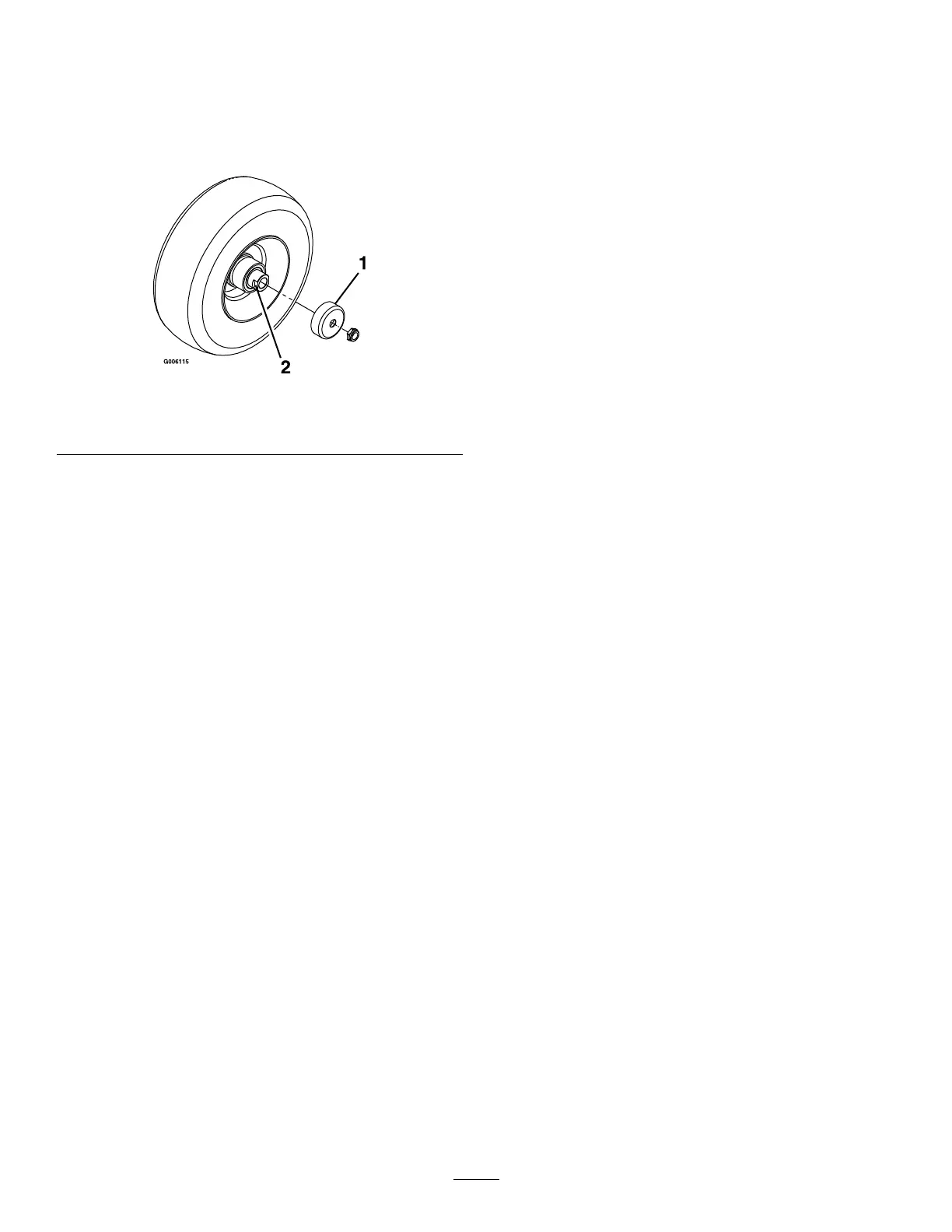

Figure40

1.Sealguard2.Spacernutwithwrench

ats

2.Removethecasterwheelfromthecasterforks.

3.Removethesealguardsfromthewheelhub.

4.Removeaspacernutfromtheaxleassemblyinthe

casterwheel.

Note:Thread-lockingadhesivehasbeenappliedto

lockthespacernutstotheaxle.Removetheaxle(with

theotherspacernutstillassembledtoit)fromthe

wheelassembly.

5.Pryoutthesealsandinspectbearingsforwearor

damage,andreplaceifnecessary.

6.Packthebearingswithageneral-purposegrease.

7.Insert1bearingand1sealintothewheel.

Note:Replacetheseals.

8.Iftheaxleassemblyhashadbothspacernutsremoved

(orbrokenloose),applyathread-lockingadhesiveto1

spacernutandthreaditontotheaxlewiththewrench

atsfacingoutward.

Note:Donotthreadthespacernutallthewayonto

theendoftheaxle.Leaveapproximately3mm(1/8

inch)fromtheoutersurfaceofthespacernuttothe

endoftheaxleinsidethenut.

9.Inserttheassemblednutandaxleintothewheelonthe

sideofthewheelwiththenewsealandbearing.

10.Withtheopenendofthewheelfacingup,llthearea

insidethewheelaroundtheaxlefullofgeneral-purpose

grease.

11.Insertthesecondbearingandthenewsealintothe

wheel.

12.Applyathread-lockingadhesivetothesecondspacer

nutandthreaditontotheaxlewiththewrenchats

facingoutward.

13.Torquethenutto8to9N∙m(71to80in-lb),loosenit,

thentorqueitto2to3N∙m(20to25in-lb).

Note:Makesurethattheaxledoesnotextendbeyond

eithernut.

14.Installthesealguardsoverthewheelhubandinsertthe

wheelintothecasterfork.

15.Installthecasterboltandtightenthenutfully.

Important:Topreventsealandbearingdamage,check

thebearingadjustmentoftenbyspinningthecaster

tire.Thetireshouldnotspinfreely(morethan1or2

revolutions)orhaveanysideplay.Ifthewheelspins

freely,adjustthetorqueonthespacernutuntilthereisa

slightamountofdragandapplythread-lockingadhesive.

33

Loading...

Loading...