RemovingtheBlades

Replacethebladesiftheyhitasolidobject,ifabladeisoutof

balance,orifabladeisbent.Toensureoptimumperformance

andcontinuedsafetyconformanceofthemachine,use

genuineTororeplacementblades.Replacementbladesmade

byothermanufacturersmayresultinnonconformancewith

safetystandards.

1.Holdthebladeendusingaragorathicklypadded

glove.

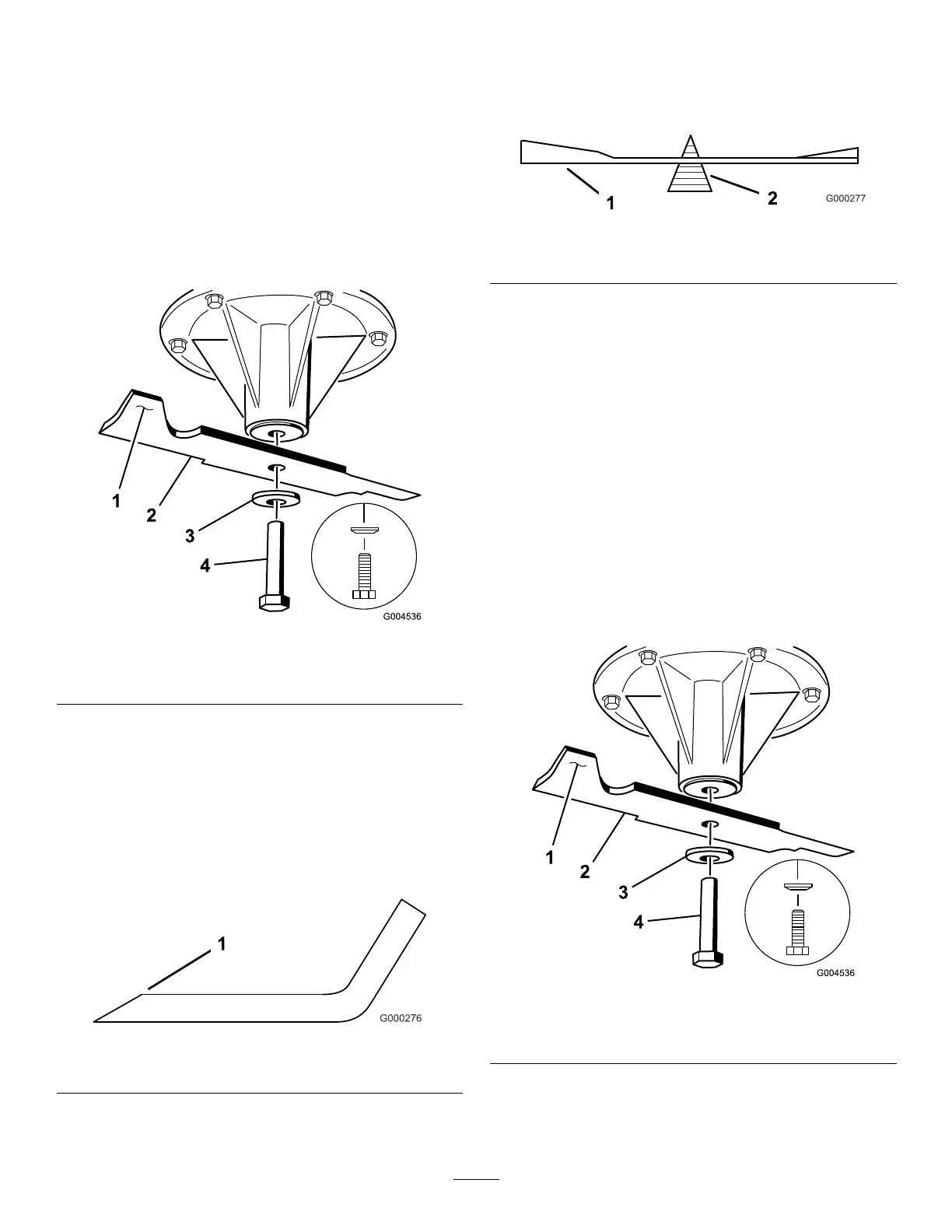

2.Removethebladebolt,thecurvedwasher,andthe

bladefromthespindleshaft(Figure78).

Figure78

1.Sailareaoftheblade3.Curvedwasher

2.Blade4.Bladebolt

SharpeningtheBlades

1.Usealetosharpenthecuttingedgeatbothendsof

theblade(Figure79).

Note:Maintaintheoriginalangle.

Note:Thebladeretainsbalanceifthesameamount

ofmaterialisremovedfrombothcuttingedges.

Figure79

1.Sharpenattheoriginalangle

2.Checkthebalanceofthebladebyputtingitonablade

balancer(Figure80).

Note:Ifthebladestaysinahorizontalposition,the

bladeisbalanced.

Figure80

1.Blade2.Balancer

3.Ifthebladeisnotbalanced,lesomemetalofftheend

ofthesailareaonly(Figure78).

4.Repeatthisprocedureuntilthebladeisbalanced.

InstallingtheBlades

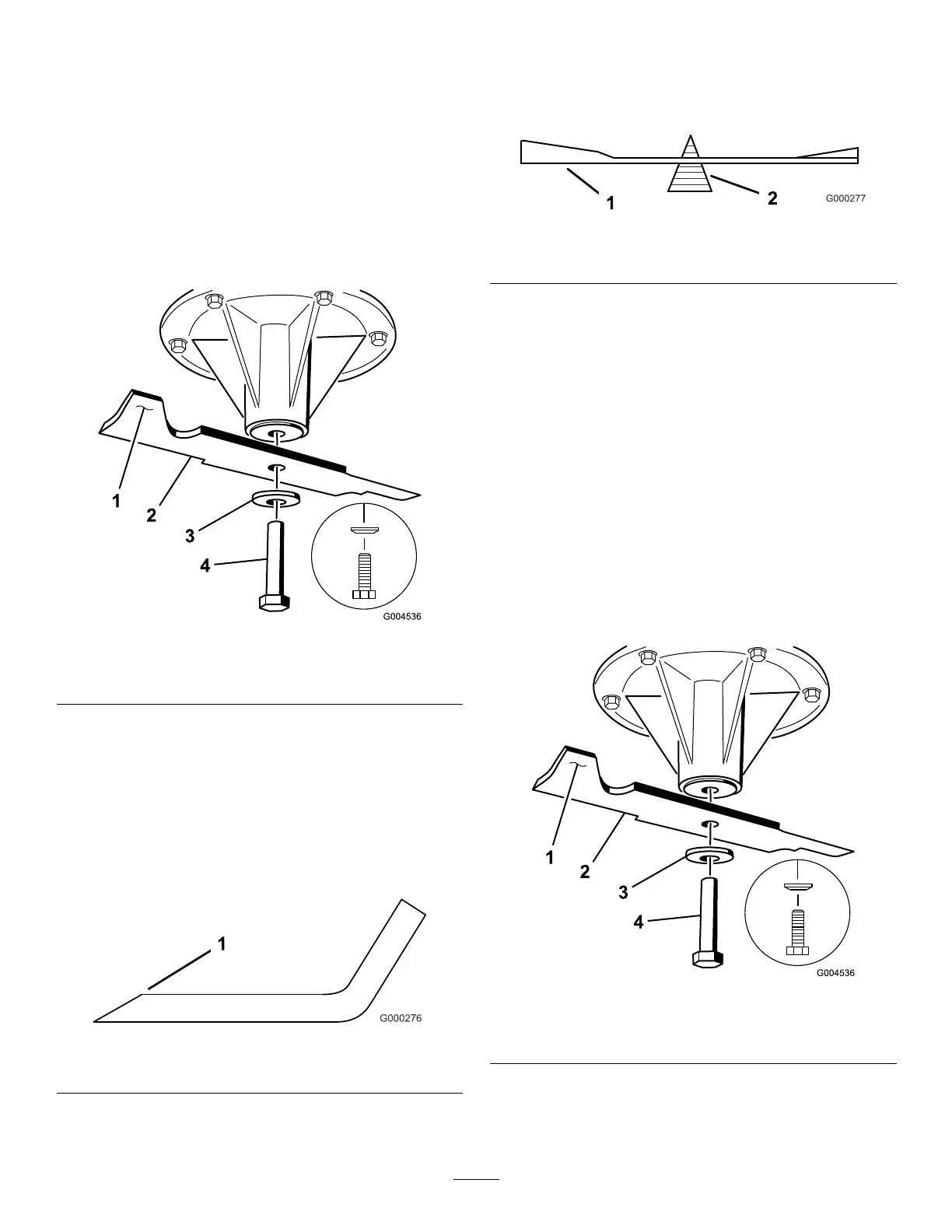

1.Installthebladeontothespindleshaft(Figure81).

Important:Thecurvedpartoftheblademustbe

pointingupwardtowardtheinsideofthemowerto

ensurepropercutting.

2.Installthespringdiskandbladebolt(Figure81).

Note:Thespring-diskconemustbeinstalledtoward

thebolthead(Figure81).

3.Torquethebladeboltto115to150N∙m(85to

110ft-lb).

Figure81

1.Sailareaoftheblade3.Springdisk

2.Blade4.Bladebolt

55

Loading...

Loading...