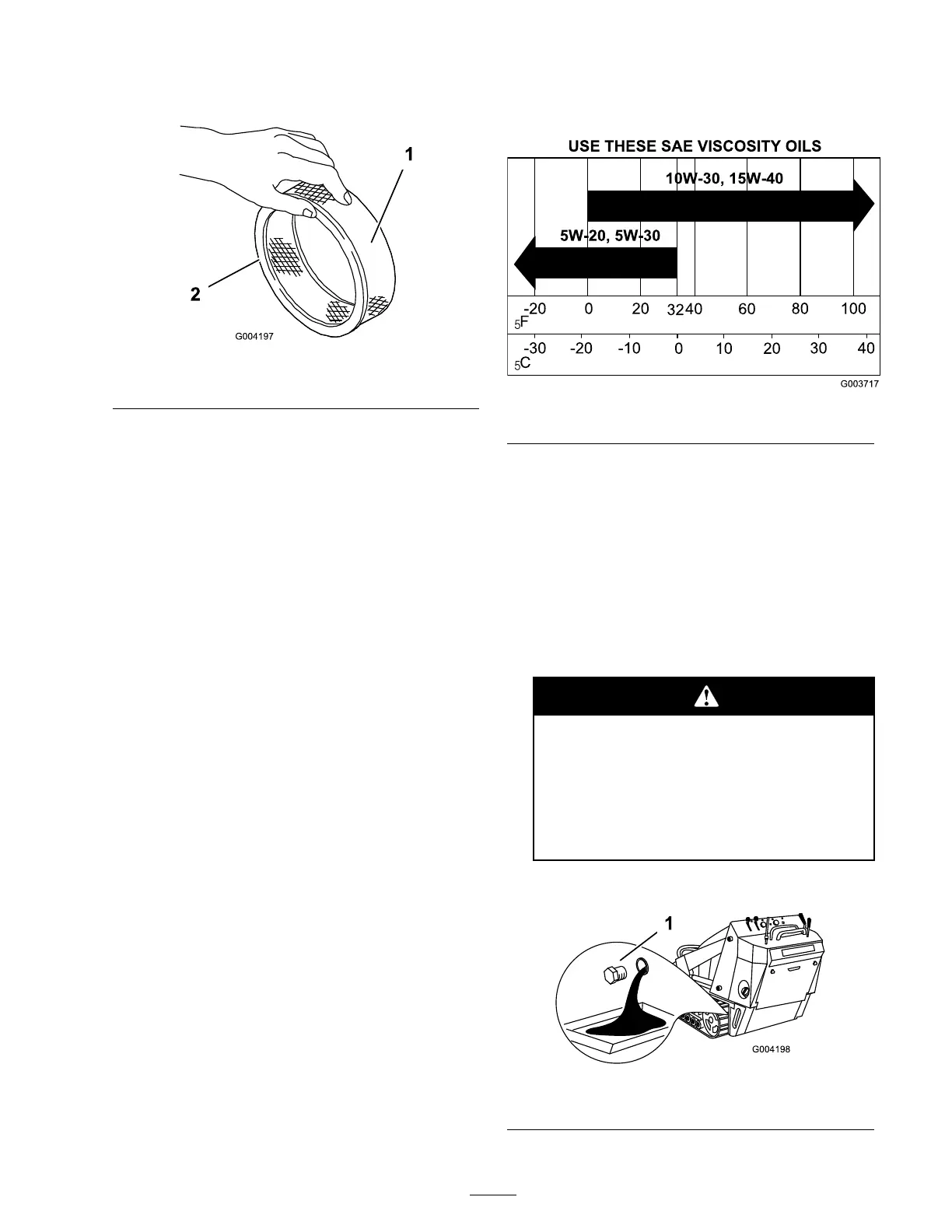

5. Lightly tap the paper filter on a flat surface to

remo v e dust and dir t ( Figure 27 ).

Figure 27

1. Paper element 2. Rubber seal

6. Inspect the paper filter for tears , an oily film,

and damag e to the r ubber seal.

Important: Nev er clean the paper

element with pr essuriz ed air or liquids,

such as solv ent, gas, or k er osene. R eplace

the paper element if it is dama ged, or

cannot be cleaned thor oughl y (i.e., after

appr o ximatel y 100 operating hour s).

Installing the Filters

Important: T o pr ev ent engine dama ge,

al w ays operate the engine with the complete

f oam and paper air cleaner assembl y installed.

1. Carefully slide the foam pre-filter onto the

paper filter ( Figure 27 ).

2. Place the air cleaner assembly onto the air

cleaner base ( Figure 25 ).

3. Install the co v er , spacer and secure it with the

co v er n ut ( Figure 25 ). T or que the n ut to 95

inc h-lb (11 N ⋅ m).

4. Install the air cleaner co v er and secure with the

knob ( Figure 25 ).

5. Close the hood.

Servicing the Engine Oil

Chang e oil after the first 50 operating hours and

then ev er y 100 operating hours thereafter .

Note: Chang e oil more frequently when

operating conditions are extremely dusty or sandy .

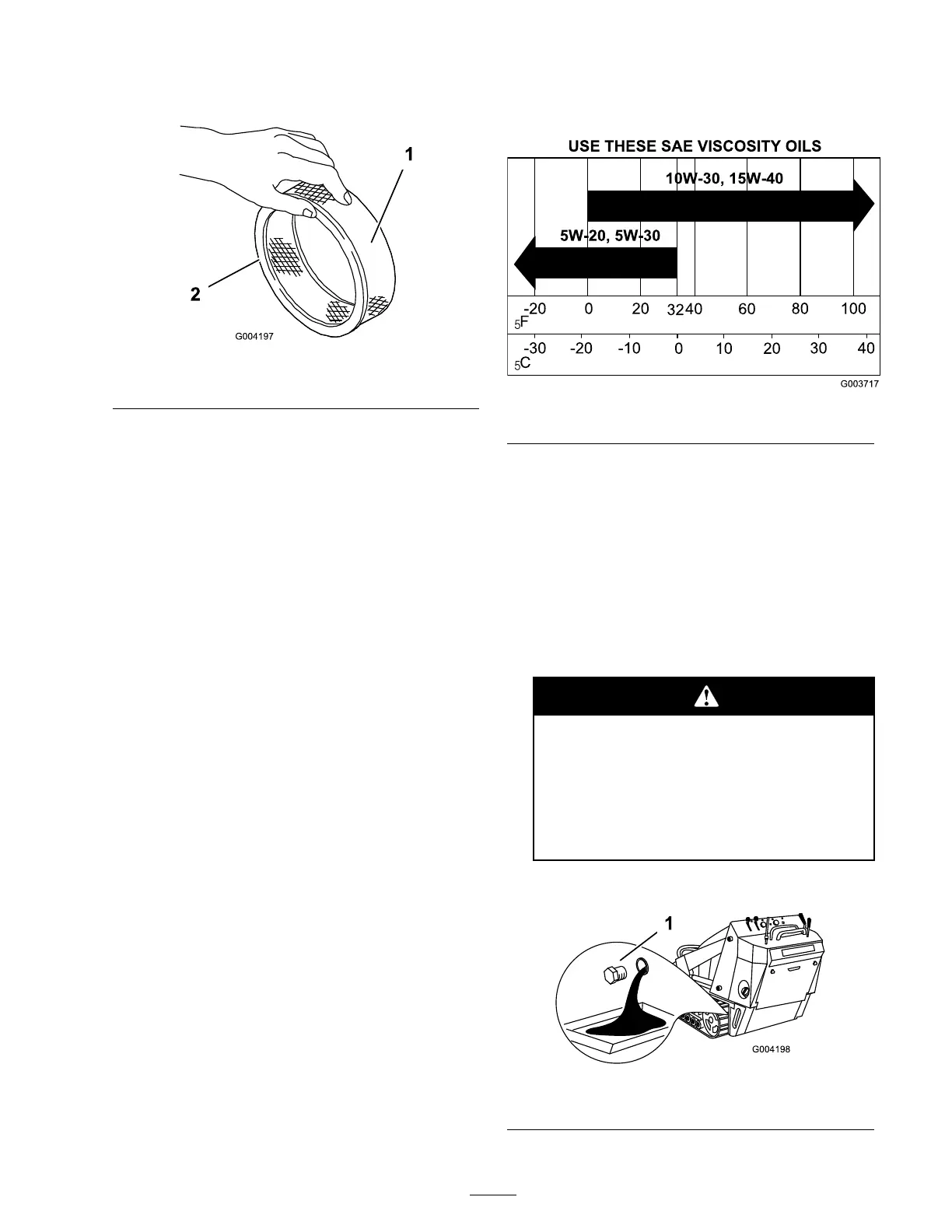

Oil T ype: Deterg ent oil (API ser vice SG , SH, SJ ,

or higher)

Crankcase Capacity: w/filter , 2.1 qt. (2 l)

Viscosity: See table belo w

Figure 28

Changing the Oil

1. Star t the engine and let it r un for fiv e min utes .

T his w ar ms the oil so it drains better .

2. P ark the traction unit so that the drain side is

slightly lo w er than the opposite side to ensure

that the oil drains completely .

3. Lo w er the loader ar ms , set the parking brak e ,

stop the engine , and remo v e the k ey .

Components will be hot if the traction

unit has been r unning . If y ou touch hot

components y ou may be bur ned.

Allo w the traction unit to cool bef or e

perf or ming maintenance or touching

components under the hood.

4. R emo v e the drain plug ( Figure 29 ).

Figure 29

1. Oil drain valve

29

Loading...

Loading...