EM-6

ENGINE MECHANICAL - Diesel Engine Diagnosis

4. IMPROPER INJECTION

TIMING

5. IMPROPER OPERATION OF

NOZZLE OR DELIVERY VALVE

Refer to item 7 of ENGINE CRANKS NORMALLY

BUT Will NOT START, above.

With engine idling, loosen the injection pipe to .

each cylinder in order. and check if the idle speed

changes .

If no change, a faulty cylind er is indicated.

Check according to following procedure .

• Faulty Nozzle or Nozzle Holder

Check nozzle with nozzle tester . (See page FU- 6)

Opening presure: 135 - 155 kg/cm' -

11,92 0 - 2 ,2 05 psi)

(13,239 - 15,200 kPal

If pressure is not within specification . l'\OZZle

is faulty and -injection -pressure shou ld be

readjusted . (See page FU-8)

• Faulty Delivery Valve

If injection pressure is within specification , delivery

valve is defectiv e and should be replaced.

ENGINE SUDDENLY STOPS

(Poaible Cause)

1. ENGINE WILL NOT RE-START

2. ROUGH IDLE

3. MALFUNCTION OF FUEL-CUT

SOLENOID

4 . NO FUEL INTO INJECTION

PUMP

(Check Procedure and Correction M ethod)

Check to see if engine re-starts according to

prescribed procedure.

If not refer to ENGINE CRANKS NORMALLY BUT

WIL L NOT START. above, and repair as necessary.

If idle is not stable, refer to ROUGH IDLE WITH

WARM ENGINE and repair accordingly .

Refer to ENGINE CRANKS NORMALLY BUT Will

NOT START. above. and chec k accord ingly.

NOTE : No operation noise from the fuel cut

solenoid may be due to loose electrical

connect ions, so check connectors before

Pf'OCHdlng with further repair s.

Ref!lf . to item 3 of ENGINE CRANKS NORMALLY

BUT WILL NOT START, above.

ENGINE MECHANICAL - Diesel Engine Diagnosis

EM-7

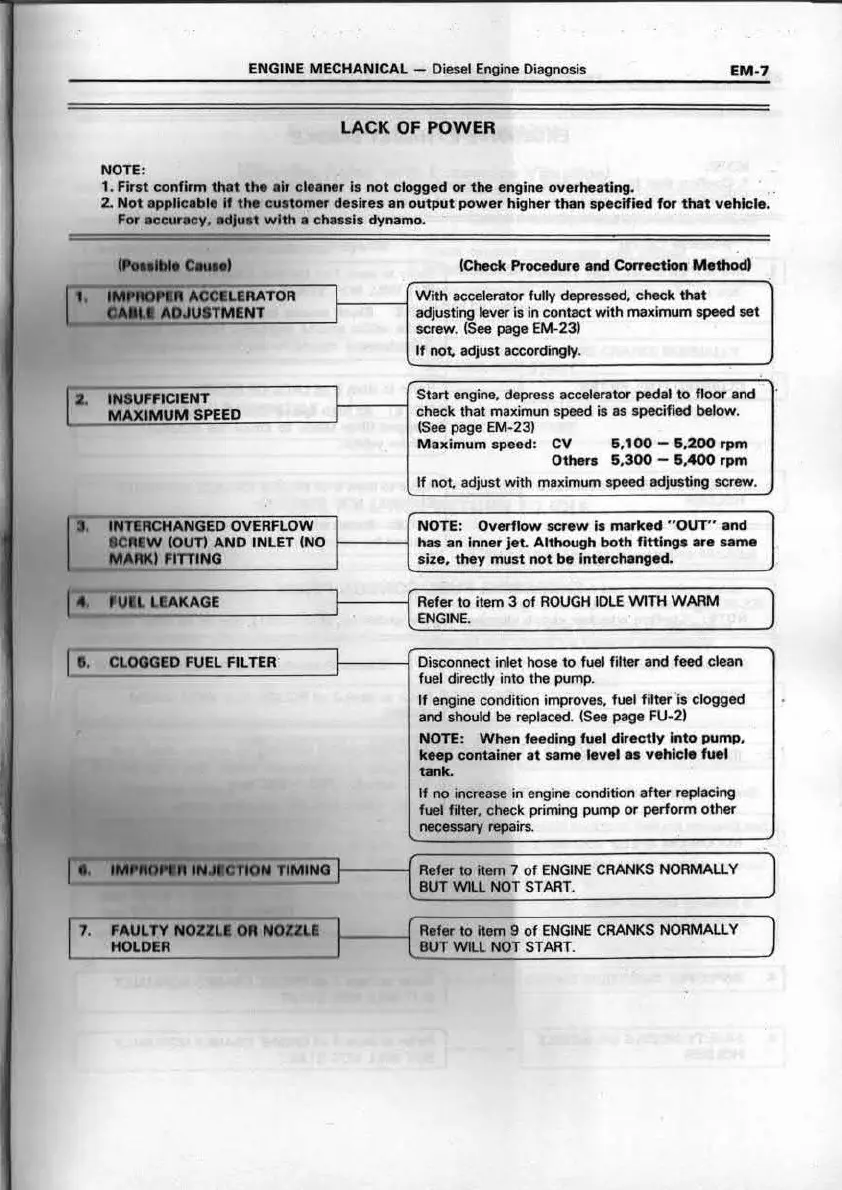

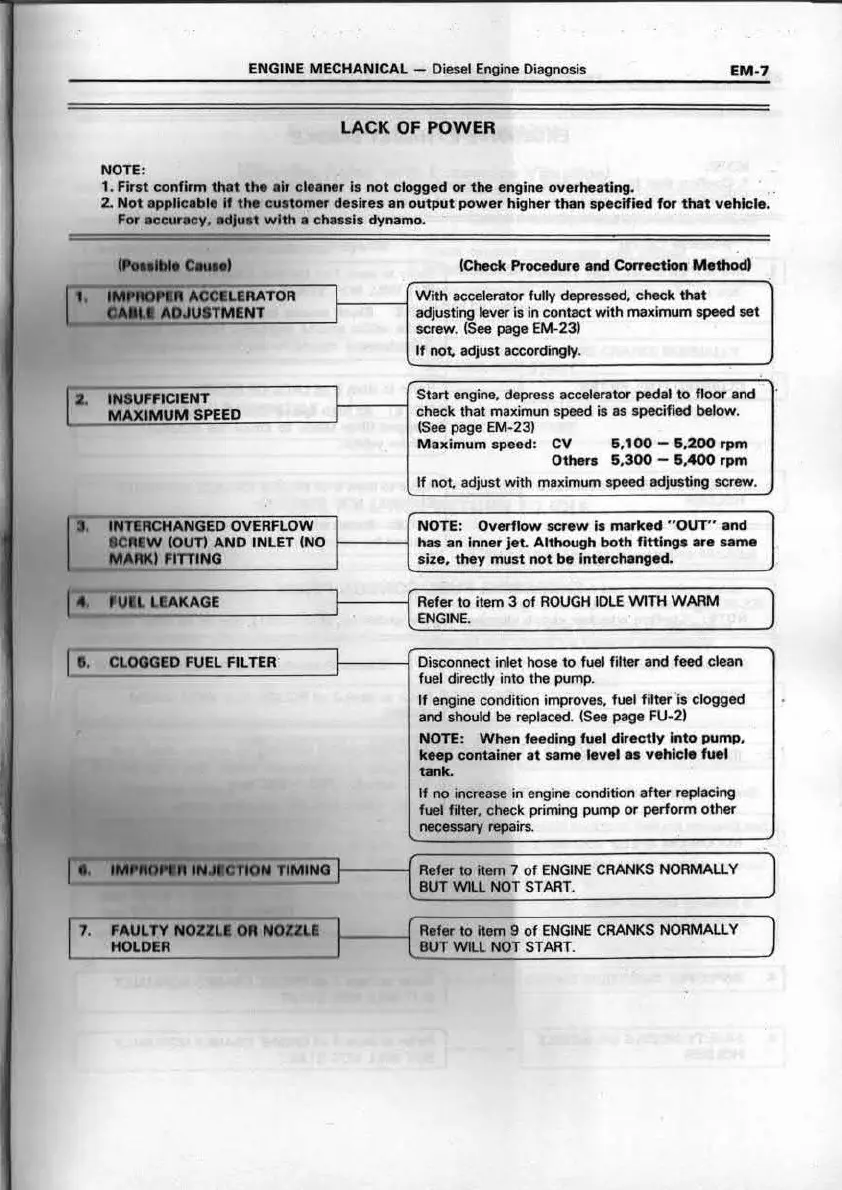

LACK OF POWER

NOTE:

1. First confirm that the air c leaner Is no t clogge d or t he engine ove rheating . . .

2. Not eppllceble If the cuetomer desires an output p0wer higher than specifi ed for tha t vehicle .

For eocureoy, edJuet with • chassis dynamo.

........c.u.,

IMPIIOPIII ACCILERATOR

GAIi.i ADJUITMENT

(Check Procedure end Correction Method)

11--- --i With accelerator fully depressed, check that

I adjusting lever Is in contact with maximum speed set

screw . (See page EM-23)

If not adjust accordingly .

I

:a. INSUFFICIENT I Start engine. depre ss accelerator pedal to floor end

MAXIMUM SPEED ,1-- -----i check that maximun speed is as specifi ed below .

'---""""'"""';;.;.;.;.=.c.:_.c..---- - --~ (See page EM- 23)

, INTIRCHANGED OVERFLOW

ICM W (OUT) AND INLET (NO

MAIIKI FITTING

M aximum speed : CV 5,100 - 5,200 rpm

Others 5 ,300 - 5,400 rpm

If not. adjust with maximum speed adjusting screw .

NOTE : Overflow screw Is marked " OUT" end

t----l has an Inner jet. Although both fitting s ere same

size. they must not be Interchanged.

1-- -- --l Refer to item 3 of ROUGH IDLE WITH WARM

PUIL LIAKAGE

'-------- --- -__J ENGINE.

I I , CLOGGED FUEL FILTER '

1

1-----< Disconnect inlet hose to fuel filter and feed clean

'----------- -- ---'

1

fuel directly into the pump .

If engine cond ition improves , fuel filter 'is clogged

and should be replaced. (See page FU-2)

NOTE : When fee ding fuel direct ly Into pump,

keep container at same leve l ea vehicle fuel

tank.

If no increase in engine conditi on after replacing

fuel fitter, check priming pump or perform other

necessary repairs.

I. INJICfflON TIMING 1---- -i Refer to item 7 of ENGINE CRANKS NORMALLY

7. PAUL TY NOZZLI OIi NOzal

HOLDER

BUT Will NOT ST ART.

1------l Refer to item 9 of ENGINE CRANKS NORMALLY

BUT WILL NOT START.

Loading...

Loading...