EM-16

ENGINE MECHANICAL - Engine Tune-up

. . (

' l .

Z'\~

ENGINE TUNE-UP ·

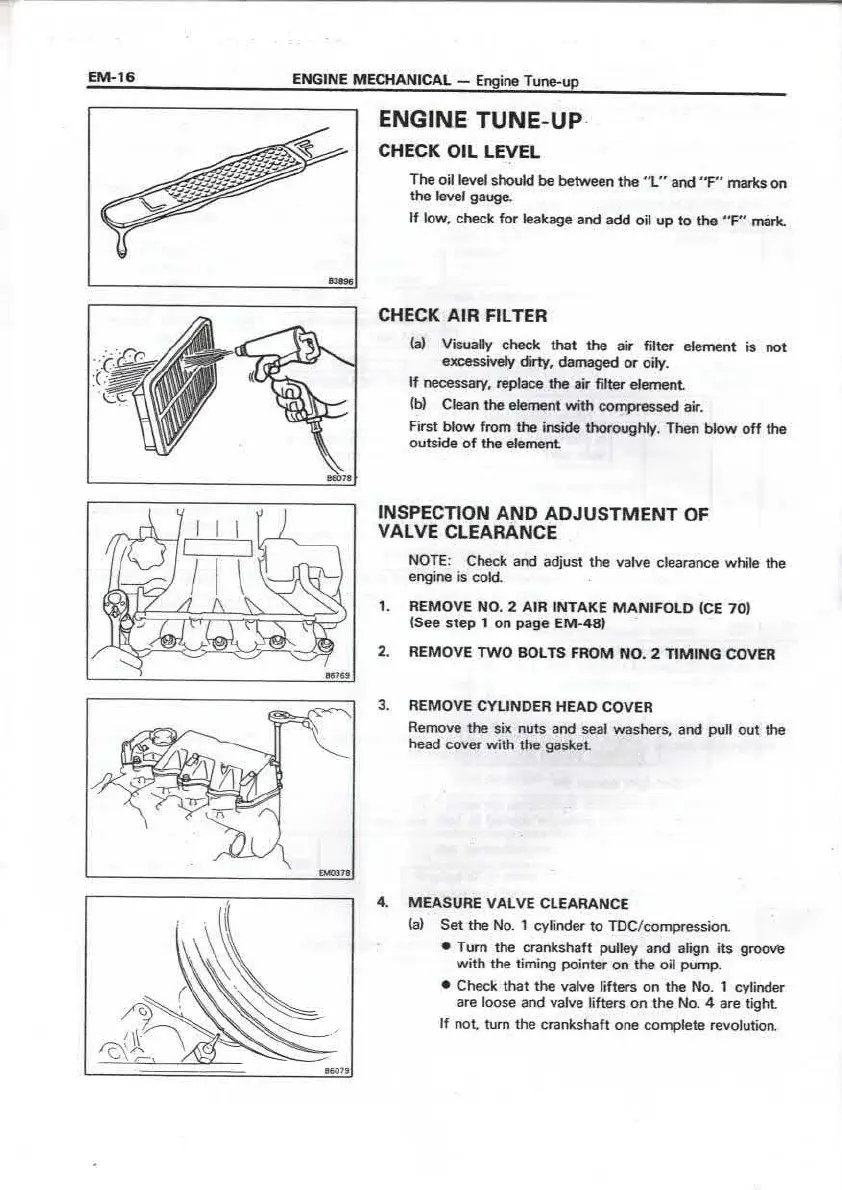

CHECK OIL LEVEL

The oil level should be between the " L" and " F" marks on

the level gauge.

If low, check for leakage and add oil up to the "F" mark.

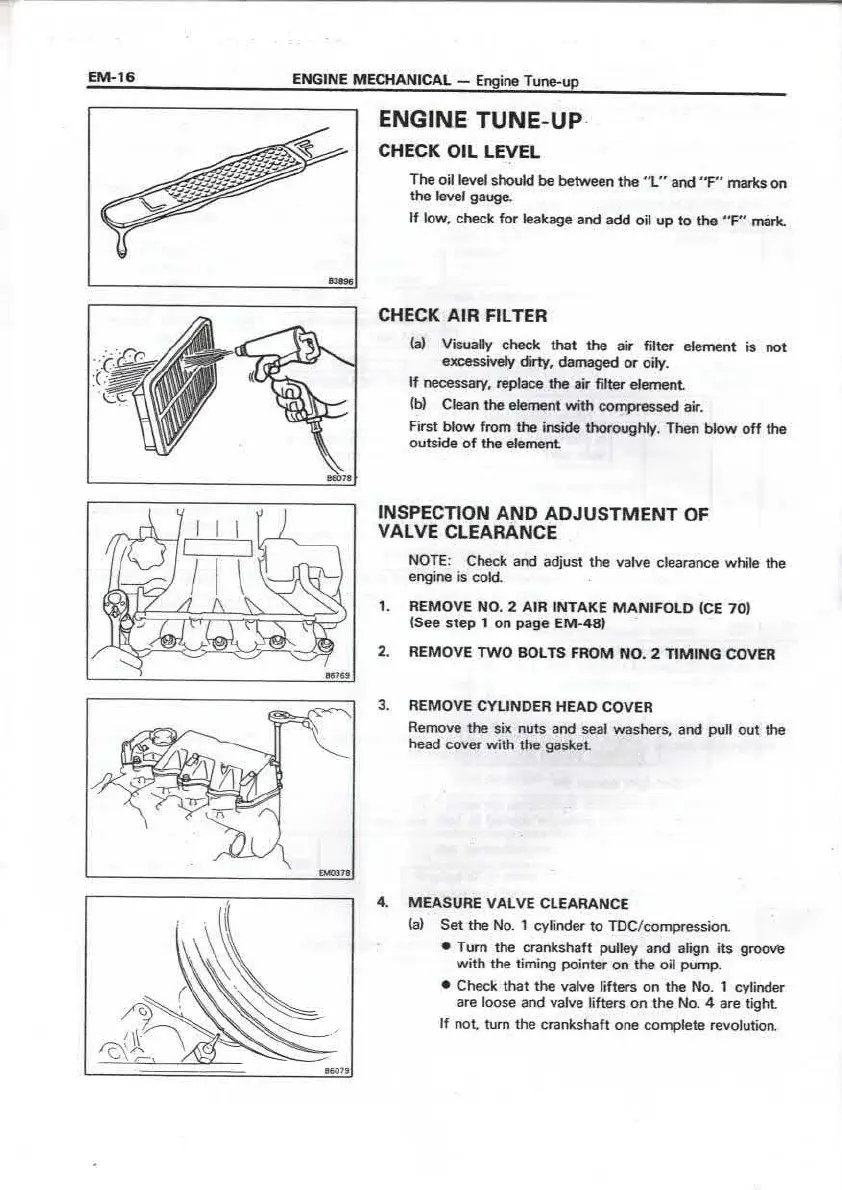

CHECK AIR FILTER

!al Visually check that the air fit ter element is not

excessively dirty, damaged or oily.

tf necessary, replace the air fil ter element

(bl Clean the element with compressed air.

First blow from the inside thoroughly . Then blow off the

outside of the element

INSPECTION AND ADJUSTMENT OF

VALVE CLEARANCE

NOTE: Check and adjust the valve clearance white the

engine is cold.

1. REMOVE NO. 2 A IR INTAKE MANIF OLD ICE 70)

(See step 1 on page EM- 48 )

2. REM OVE TWO BOLTS FROM NO. 2 TIMING COVER

3. REMOV E CYLIND ER HEAD COV ER

Remove the six nuts and seal washers. and pull out the

head cover with the gasket

4. MEAS URE VALVE CLEARANCE

(al Set the No. 1 cylinder to TDC/ compression

• Tum the crankshaft pulley and align its groove

wit h the t iming pointer on the oil pump .

• Check that the valve lifters on the No. 1 cylinder

are loose and valve Utters on the No. 4 are tight

If not tum the crankshaft one complete revolut ion.

ENGINE MECHANICAL - Engine Tune-up

EM-'17

,.. Front

EX

IN IN

,.. Front

EX

o,am

11m

IN IN

Intake side:

New shim t hick.ness

= T + [A - 0.25 mm

(0.00 98 in.I]

Ex haust sid e:

New shim t hick ness

= T + [A - 0.30 mm

(0.01 18 in.)]

Oid 1H

(b) Measure the clearance of half of the valves.

• Measure only th ose valves indicated in th e f igure.

• Record the measurements w hich are out of

specification . They wiU be used later to determine

the required replacement shims,

Valv e clearanc e (Cold ):

Inta ke 0 .20 - 0.30 mm (0.008 - 0.012 in .I

Ex haust 0 .25 - 0.35 mm (0 .010 - 0.014 in.I

(cl Tum the crankshaft pulley one revolution and

measure the other valves.

• Tum the crankshaft pulley one revolution and align

its groove and timing poi nter on the oil pump.

• Measure only the valves indicated by the arrows in

the figure.

5 , ADJ UST VALVE CLEARANCE

NOTE: Vnlve clearance is adjusted one cylinder at a time.

(o) Turn the cronkshaft pulley to position the intake

com1holt lobe 11f the cylinder upward.

(hi Po11tlon lhe notch of lhe lifter so that ii is accessible

w11h • , moll aerewdrtver.

(cl Pince the SST between the two cams and tum the

hondle 10 press down the valve Utters .

SST 09248 -64010

NOTE: Make sure the SST is installed so that it presses

evenly on both lifters.

(d) Using a small screwdriver and magnet remove the

shims.

(el Determine the replacement shim size by using the

follow ing Formula and Charts .

• Using a micrometer. measure the thickness of the

shim that was removed.

• Calculate the thickness of a new shim so that the

valve clearance comes within the specified value.

T . . . . .. Thickness of shim used

A . , ... . Valve clearance measured

• Select a shim with a thickness as close as possible

to the calculat ed value.

NOTE: Shims are available in 25 sizes. in increments of

0.050 mm (0.0020 in.I. from 2.200 mm (0.0866 in.I to

3.400 mm (0.1339 in.l. Thickness is stamped o n the new

shims.

Loading...

Loading...