ST-14

STARTING SYSTEM - Starter

INSPECTION OF STARTER

Armature Coil

1. INSPECT THAT ARMATURE IS NOT GROUNDED

Using an ohmmeter, check that there is no continuity be-

tween the commutator and armature coil core.

If there is continuity, replace the armature.

2. INSPECT ARMATURE FOR OPEN CIRCUIT

Using an ohmmeter, check for continuity between the

segments of the commutator.

If there is no con tinuity between any segment replace the

armature.

Commutator

1. INSPECT COMMUTATOR FOR DIRTY ANO BURNT

SURFACES

If the surface is dirty or burnt correct with sandpaper !No.

400) or a lathe.

2 . INSPECT COMMUTATOR CIRCLE RUNOUT

Maximum circle runout: 0.05 mm (0.0020 in.)

If the circle runout is greater than the maximum , correct

with a lathe.

3. MEASURE DIAMETER OF COMMUTATOR

Using calipers, measure the diameter of the commutator.

Minimum diameter: 1.4 kW 29 mm (1.14 inJ

2.0 kW 34 mm (1.34 in.I

2.5 kW 35 mm (1.38 in.)

If the diameter of the commutator is less than the

minimum, replace the armature .

4 . INSPECT UNDERCUT DEPTH

Check that the undercut depth is clean and free of foreign

particles. Smooth out the edge.

Minimum undercut depth: 0 .2 mm (0.008 in.I

Standard undercut depth:

1.4 kW 0.5 - 0.8 mm (0.020 - 0.032 in.)

2.0 kW, 2.5 kW 0.7-0.9 mm (0.028 -0.035 in.)

If the undercut depth is less than the minimum, correct

with a hacksaw blade.

STARTING SYSTEM - Starter

ST-15

ST0019

sr..,.,

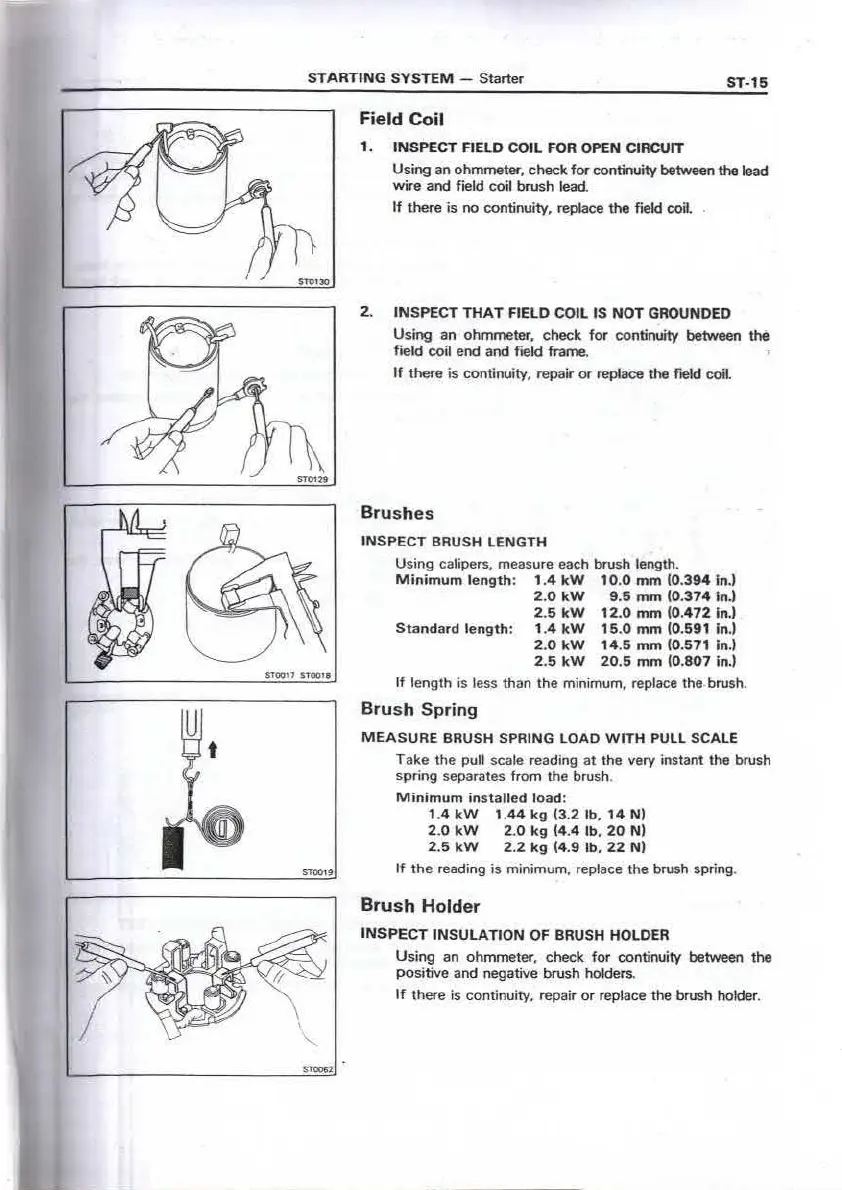

Field Coil

1. INSPECT FIELD COIL FOR OPEN CIRCUIT

Using an ohmmeter, check for continuity between the lead

wire and field coil brush lead.

If there is no continuity, replace the field coil .

2. INSPECT THAT FIEL.O COIL IS NOT GROUNDED

Using an ohmmeter, check for continuity between the

field coil end and field frame.

If there is continuity, repair or replace the field coil.

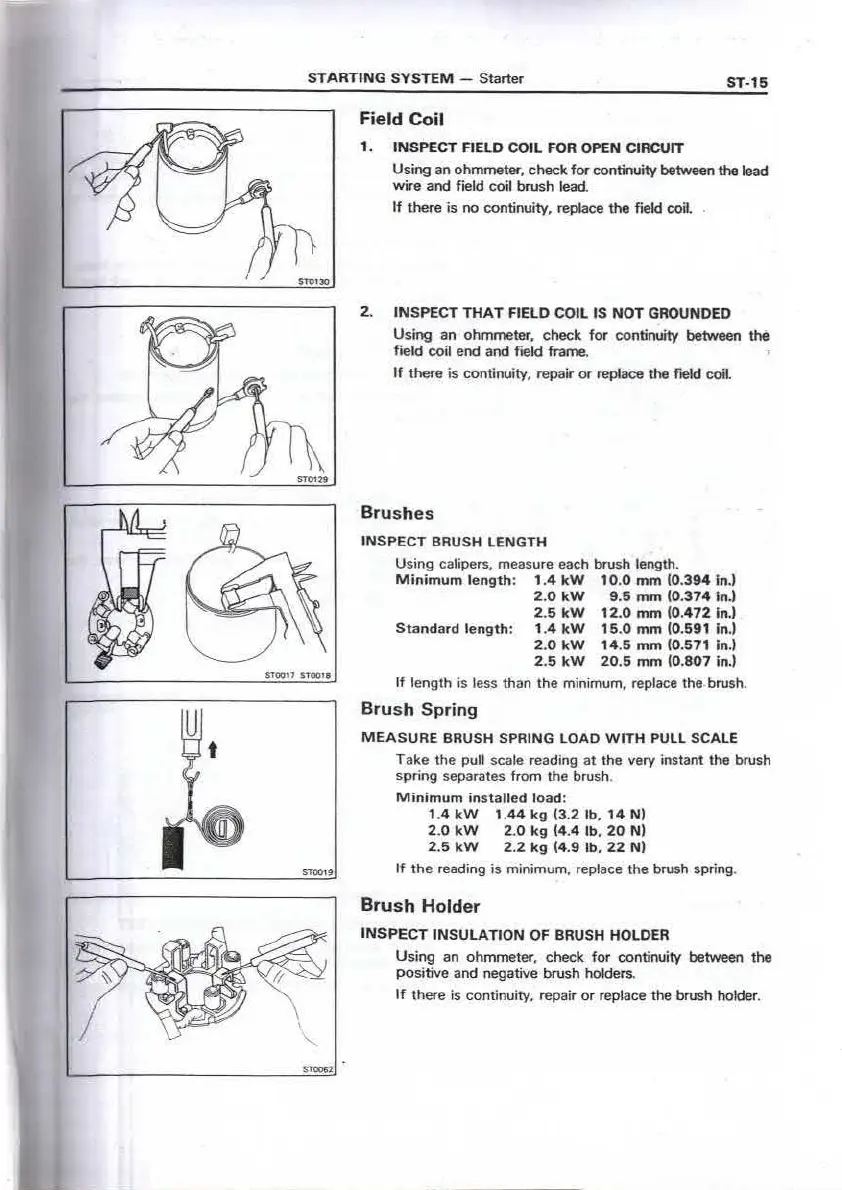

Brushes

INSPECT BRUSH LENGTH

Using calipers. measure each brush length.

Minimum length: 1.4 kW 10 .0 mm (0.39 4 in.I

2.0 kW 9.5 mm (0.374 in.)

2.5 kW 12.0 mm (0.472 in.)

Standard length : 1.4 kW 15.0 mm (0.591 in.I

2.0 kW 14 .5 mm (0.571 in.J

2.5 kW 20.5 mm (0.807 in.)

If length is less than the minimum, replace the-brush.

Brush Spring

MEASURE BRUSH SPRING LOAD WITH PULL SCALE

Take the pull scale reading at the very instant the brush

spring separates from the brush.

Minimum installed toad:

1.4 kW 1.44 kg (3.2 lb, 14 NJ

2 .0 kW 2.0 kg (4.4 lb, 20 NJ

2.5 kW 2.2 kg (4.9 lb, 22 N)

If the reading is minimum, replace the brush spring .

Brush Holder

INSPECT INSULATION OF BRUSH HOLDER

Using an ohmmeter, check for continuity between the

positive and negative brush holders.

If there is continuity, repair or replace the brush holder.

Loading...

Loading...