2.

Check the delivery valve and holder.

(1) Check the valve seat surface and piston for

scratches, dents and wear.

(2) Check the delivery valve and holder for scratches on

the contact surfaces with the injection pipe.

(3) Check the suck-back action.

(a)

Thoroughly wash the parts in light oil and do

not wipe off the oil film. Close the lower part of

the valve seat with a finger and lift the valve.

(b)

The parts are in good condition if the valve

stops at the relief valve when released.

(c)

Replace the valve if it falls to the seat.

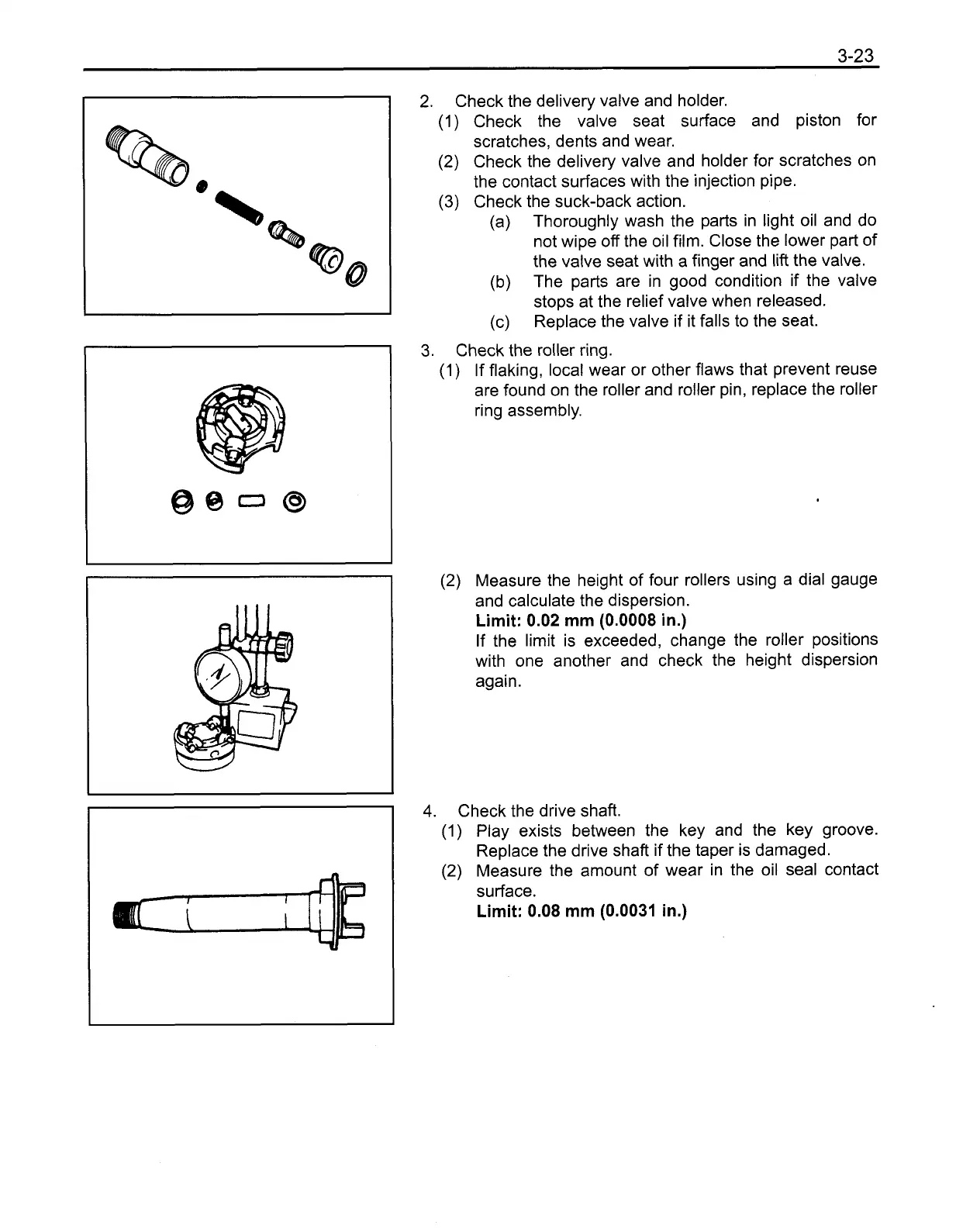

3. Check the roller ring.

(1) If flaking, local wear or other flaws that prevent reuse

are found on the roller and roller pin, replace the roller

ring assembly.

(2) Measure the height of four rollers using a dial gauge

and calculate the dispersion.

Limit: 0.02 mm (0.0008 in.)

If the limit is exceeded, change the roller positions

with one another and check the height dispersion

again.

4.

Check the drive shaft.

(1) Play exists between the key and the key groove.

Replace the drive shaft if the taper is damaged.

(2) Measure the amount of wear in the oil seal contact

surface.

Limit: 0.08 mm (0.0031 in.)

Loading...

Loading...