Chapter 6 Verifying operation and communication

90 CNT-SVX05B-EN

Building automation system

Some building automation systems can reset controller diagnostics. For

more complete information, refer to the product literature for the building

automation system.

Rover service tool

You can reset controller diagnostics with the Rover service tool (see the

Rover Operation and Programming guide, EMTX-SVX01E-EN).

Diagnostic reset input

Any device that can communicate the network variable nviRequest (enu-

meration “clear_alarm”) can reset controller diagnostics.

Zone sensor fan mode switch

When the zone sensor fan mode switch is changed from Off to Auto, the

controller attempts to reset all diagnostics. If the zone sensor fan mode

switch has been disabled by configuration, then the switch is ignored and

cannot be used to reset diagnostics.

Operator display

You can view and reset active diagnostics from the operator display.

Active diagnostics are indicated by a flashing status light on the display.

Interpreting multiple diagnostics

Two or more diagnostics can be present at the same time. Diagnostics are

reported in the order in which they occur, but each diagnostic has a differ-

ent priority. For example, if a freezestat condition occurs, the controller

communicates a Low Temp Detect diagnostic message at priority one,

shuts down the air-handler, and opens all valves. If a stop input condition

then occurs, the controller communicates a Unit Shutdown diagnostic

message at priority two. However, because the Low Temp Detect diagnos-

tic has a higher priority, the controller does not close the valves.

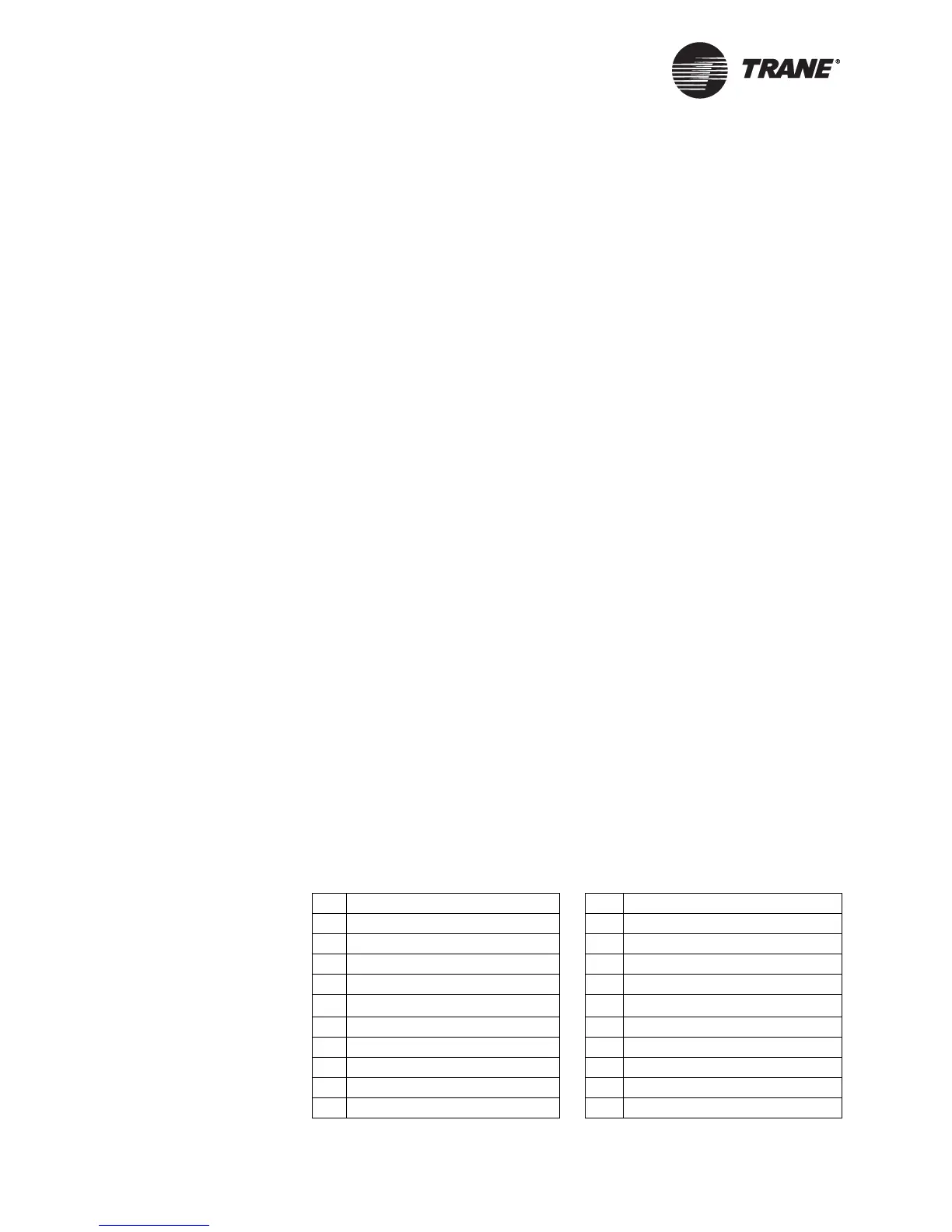

Table 62 lists the Tracer AH540/541 diagnostics in order of priority, with

1 being the highest and 22 being the lowest.

Table 62. Diagnostics in order of priority

1 Emergency Override 12 Local Fan Switch Failure

2 Manual Output Test 13 Outdoor Air Temp Failure

3 Low Temp Detect 14 Mixed Air Temp Failure

4 Unit Shutdown 15 Humidity Input Failure

5 Low Supply Fan Air Flow 16 Entering Water Temp Failure

6 Low Exhaust Fan Air Flow 17 CO

2

Sensor Failure

7 Space Temperature Failure 18 Evap Refrigerant Temp Failure

8 Duct Static Press Failure 19 Generic Temperature Failure

9 Duct Static Press High Limit 20 Dirty Filter

10 Discharge Air Temp Failure 21 Maintenance Required

11 Local Space Setpoint Failure 22 Invalid Unit Configuration

Loading...

Loading...