OIL

RELEASE VALVE AND INDICATOR

!

This unit is very reliable and should require no m;intenar.ce other than cleaning.

1

Vv'hen'the oil

is

changed

it

is

advantageous to dismantle this unit and thoroughly

wash

it

in petrcl to ensure that the piston works freely in the release valve body.

Under no circumstances should the release valve springs be t2mpered with as the

spring poundage

is

set to give the correct oil pressure. Should

it

be necessary to

/I

.'

replace these springs at any time, gencine Triumph spares should be obtained.

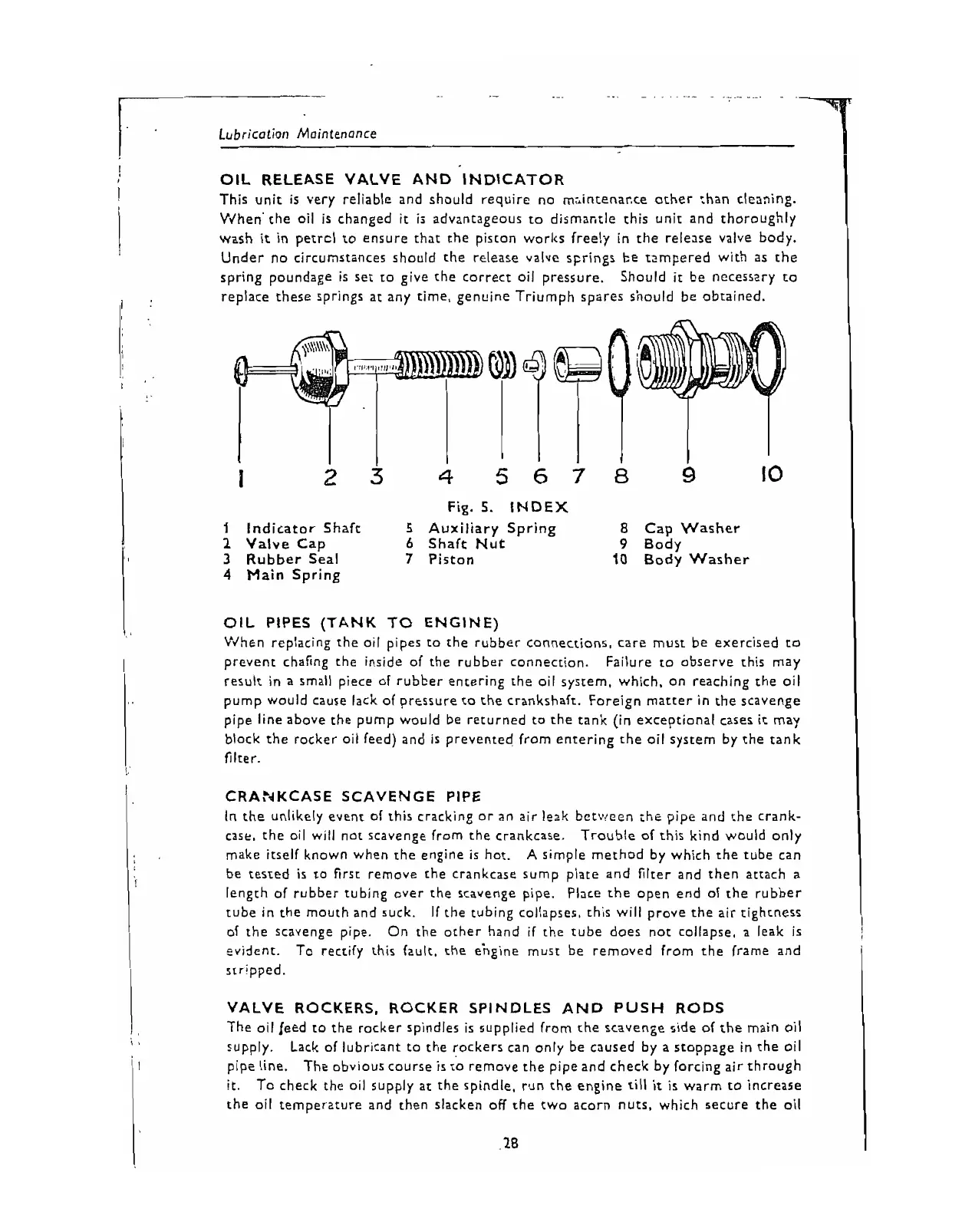

Fig.

5.

INDEX

1

Indicator Shafc

5

Auxiliary Spring

8

Cap Washer

2

Valve Cap

6

Shaft Nut

9

Body

3

Rubber Seal

7

Piston

10

Body Washer

4

Main Spring

I,

,

OIL

PIPES (TANK TO ENGINE)

When replacing the oil pipes to the rubber connections, care must be exercised to

prevent chafing the inside of the rubber connection. Failure to observe this may

result in a small piece of rubber entering the oil system, which, on reaching the oil

pump would cause lack of pressure to the crankshaft. Foreign matter in the scavenge

pipe line above the

pump would be returned to the tank (in exceptional cases

it

may

block the rocker oil feed) and

is

prevented from entering the oil system by the tank

filter.

!,'

CRANKCASE SCAVENGE PIPE

In the unlikely event ol this cracking or an

air

leak bctwcen the pipe and the crank-

case, the oil will not scavenge from the crankcase. Trouble of this kind would only

make itself known when the engine

is

hot.

A

simple method by which the tube can

be tested

is

to

first

remove the crankcase sump plate and filter and then attach a

length of rubber tubing over the scavenge pipe. Place the open end of the rubber

tube in the mouth and suck. If the tubing collapses, this will prove the air tightness

of the scavenge pipe. On the other hand if the tube does not collapse, a leak

is

evident. To rectify this fault, the e'ngine must be removed from the frame and

stripped.

VALVE ROCKERS, ROCKER SPINDLES AND PUSH RODS

The oil feed to the rocker spindles

is

supplied from the scavenge side of the main oil

i

supply.

Lack of lubricant to the rockers can only be caused by a stoppage in the oil

!

pipe line.

The obvious course

is

to

remove the pipe and check by forcing air through

it.

To check the oil supply

at

the spindle, run the engine

rill

ir

is

warm to increase

the oil temperature and then slacken off the two acorn nuts, which secure the oil

28

Loading...

Loading...