Operating manual Manual Powder System SPRINT XE

9 Troubleshooting and rectification

Order number 2354920 | Edition 01/2023 49

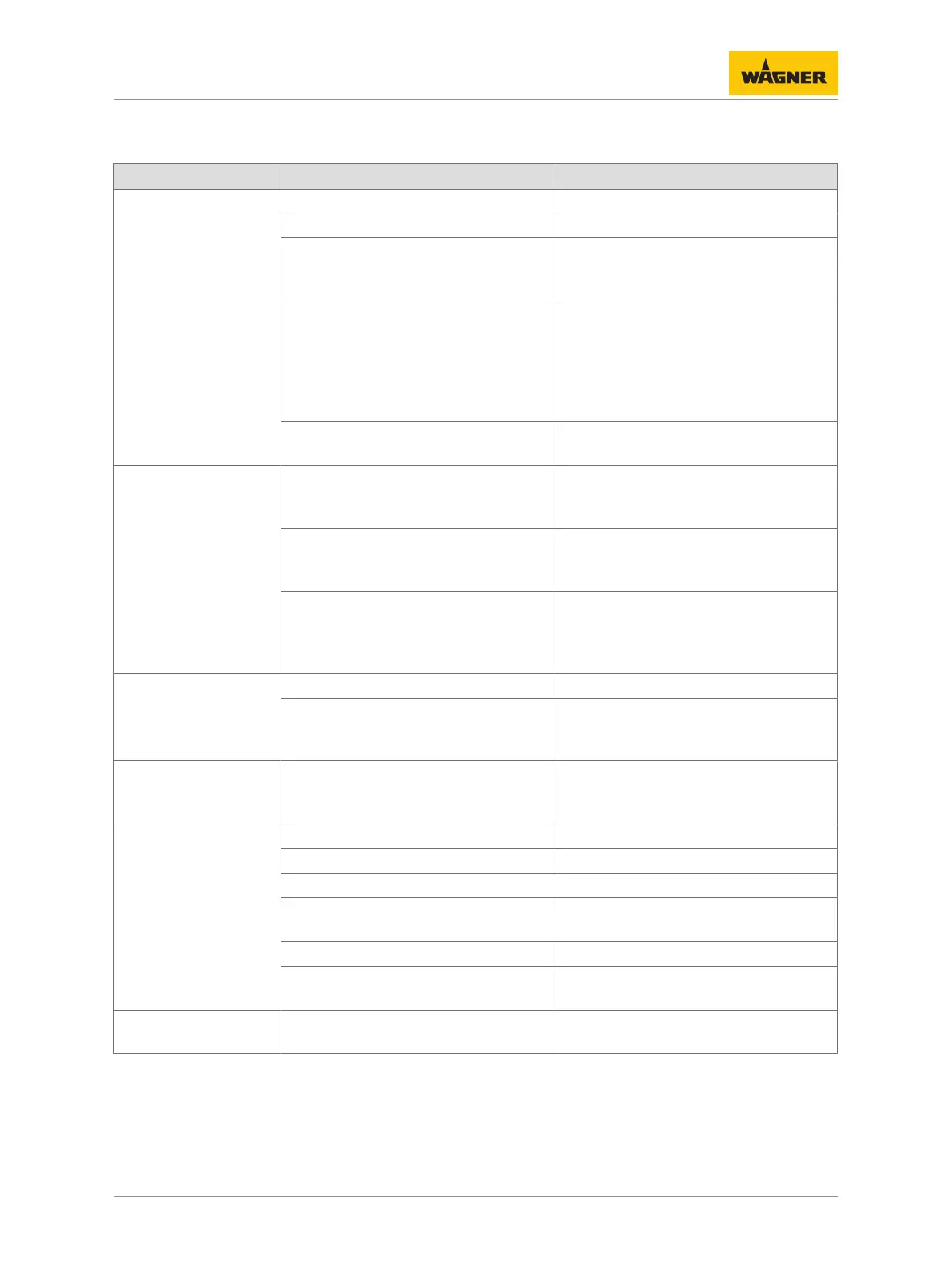

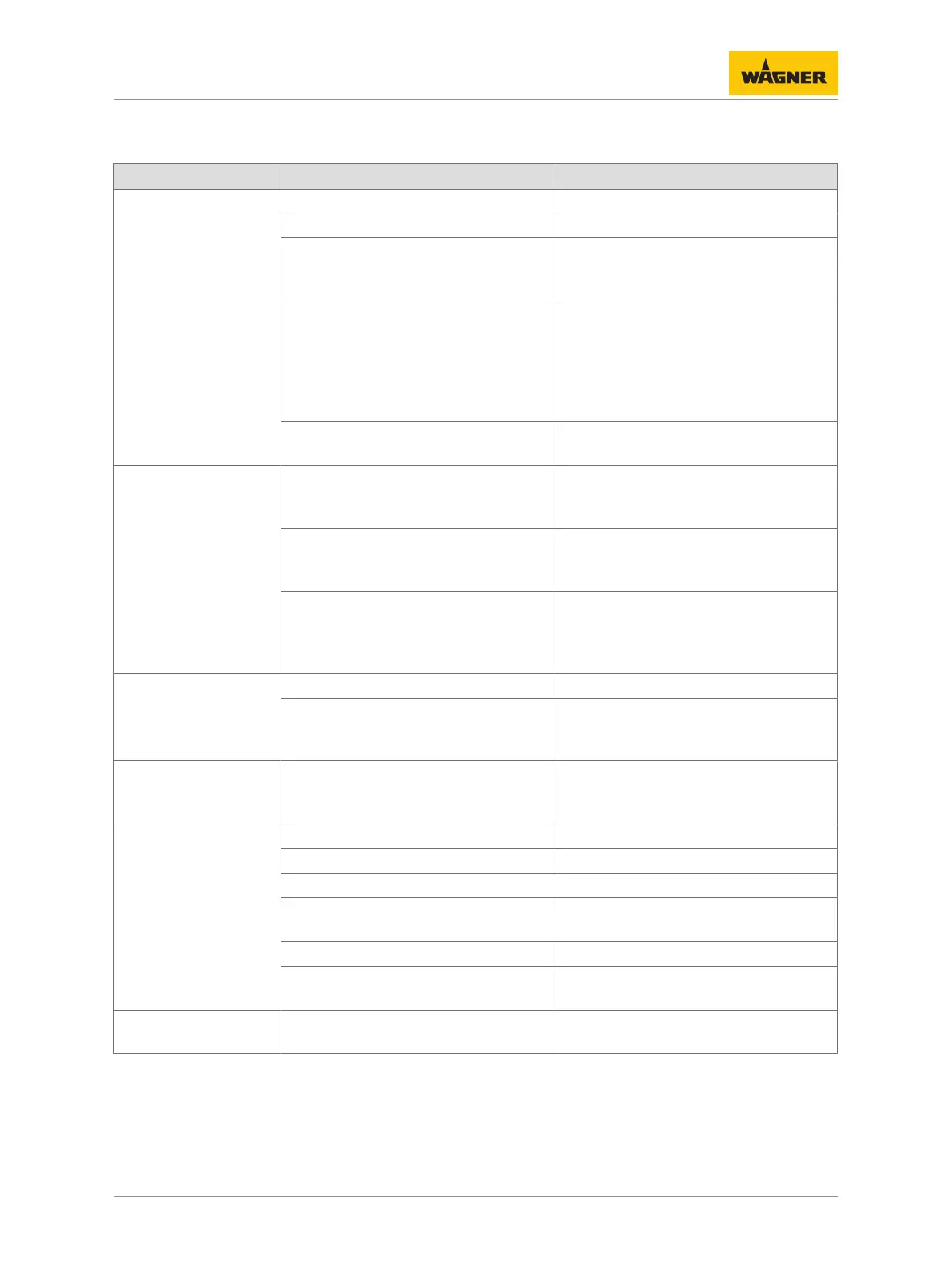

9 TROUBLESHOOTING AND RECTIFICATION

Malfunction Cause Rectification

Power indicator does

not light up

No Corona power sup-

ply

Mains supply not switched on Turn on mains.

2 AT fuses defective Replace fuses

The connection cable to the powder

spray gun is interrupted

To replace the connection cable, notify

the WAGNER service department or

qualified personnel

The powder spray gun is too close to

the work piece

Switch off the high voltage, increase the

distance between the spray gun and the

work piece and then switch the high

voltage on again Should an error mes-

sage be displayed again, inform the

WAGNER service department

The grounding between control unit

and powder spray gun is interrupted

Contact WAGNER service department

Intermittent powder

discharge

The speed in the powder feed hose is

too low

Increase the total feed and dosing air

and readjust the ratio of the airs to each

other

The cross section of the powder feed

hose is reduced by movements

Use a powder hose that prevents the

cross section from narrowing (select a

hose with a thicker wall)

Fluctuations in the compressed air

caused by short-term increase of the

compressed air consumption in the

supply system

Install compressed air storage directly in

front of high consumption system com-

ponents

Dust buildup above the

tank/powder tank

Too much fluid air. Reduce the fluid air at the throttle

The throttle is not connected to the

fluid air connection of the control unit

Connect the throttle to the fluid air con-

nection of the control unit and readjust

the fluid air volume

Bad wrap around, back-

spray

Insufficient grounding Make sure that all components are well

grounded, see chapter Grounding

[831]

No powder discharge Tank/powder tank empty Refill the powder

The spray gun is clogged Blow through the spray gun

The powder feed hose is clogged Blow through the powder feed hose

The powder suction system in the pow-

der tank is clogged

Blow through the powder suction sys-

tem

The feed air hose is kinked Straighten or replace the feed air hose

The powder feed hose is kinked Straighten or replace the powder feed

hose

The feed unit does not

sink into the powder

The guide of the feed unit holder is

jammed

Enable the guide to move smoothly

Loading...

Loading...