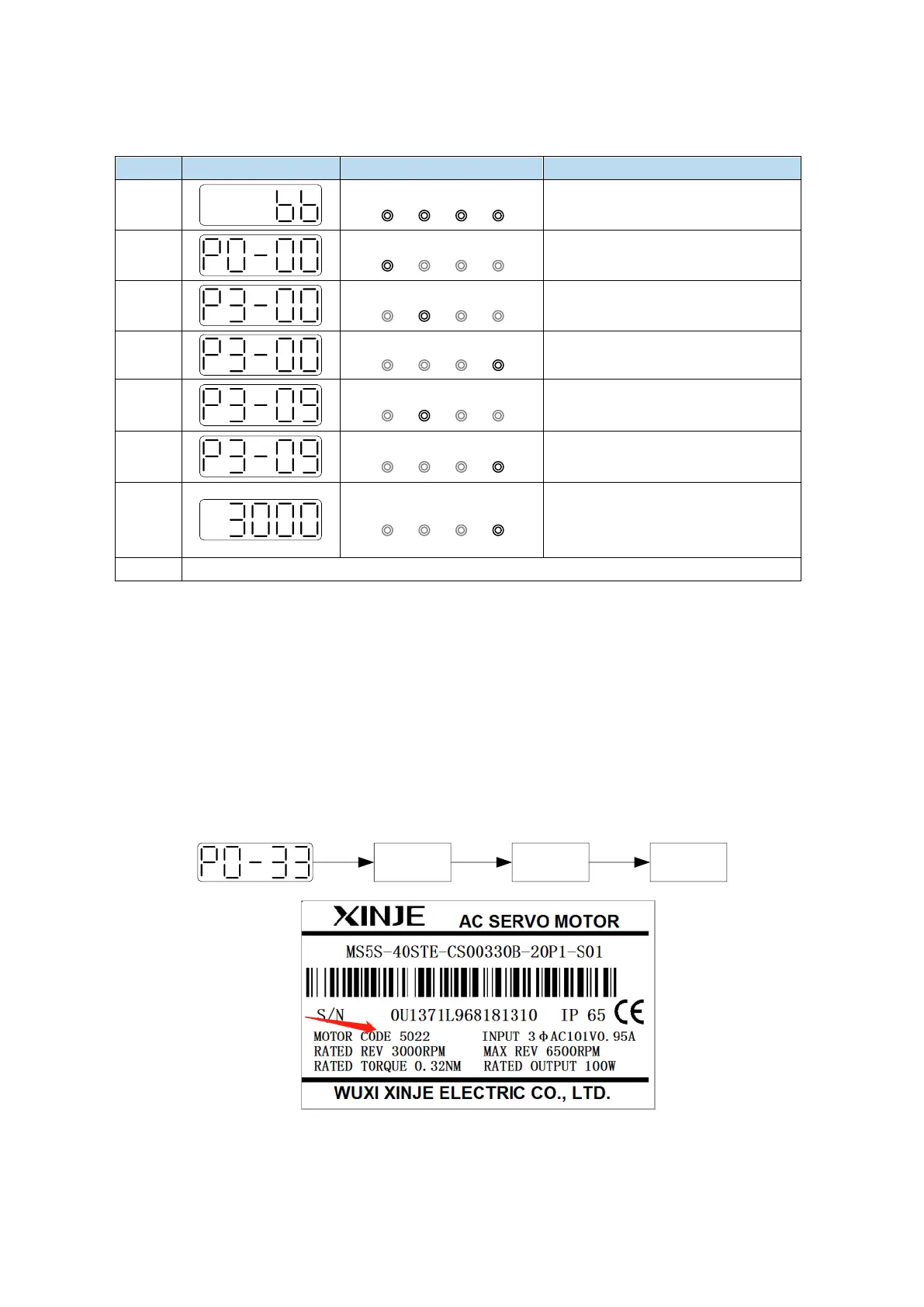

4.6 Parameter setting example

An example is given to illustrate the operation steps when the content of parameter P3-09 is changed

from 2000 to 3000.

Press INC for three times to show

P3-00

Press ENTER, the last 0 will flash

Long press ENTER to show the

value of P3-09

Press INC, DEC, ENTER to

increase decrease or shift, after

changing, long press ENTER to

confirm

Note: When the setting parameter exceeds the range that can be set, the driver will not accept the

setting value, and the driver will report E-021 (parameter setting exceeds the limit). The parameter

setting overrange usually occurs when the upper computer writes parameters to the driver through

communication.

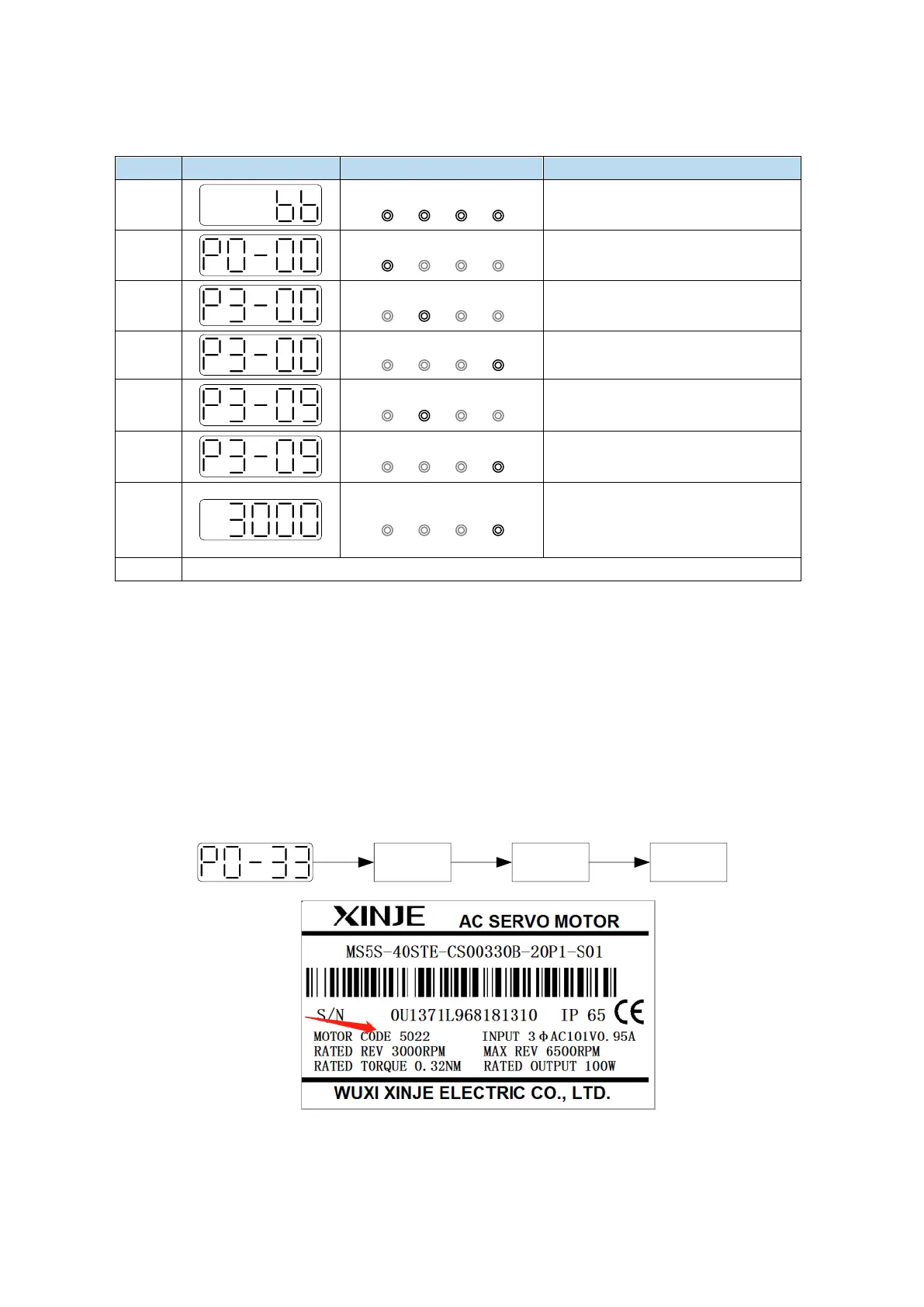

4.7 Change motor code

A servo driver can be equipped with a variety of motors with similar power levels. Different types of

motors are distinguished by the motor code on the motor nameplate. Before debugging the servo

system, make sure that the motor code U3-00 matches the motor nameplate label.

Input motor

code

Long press ENTER

Complete the

setting

confirm

Short press ENTER

Re-power on

Loading...

Loading...