Because it can only rotate in one direction, after a certain period of time, the number of revolving

cycles will always exceed the upper limit of absolute value encoder.

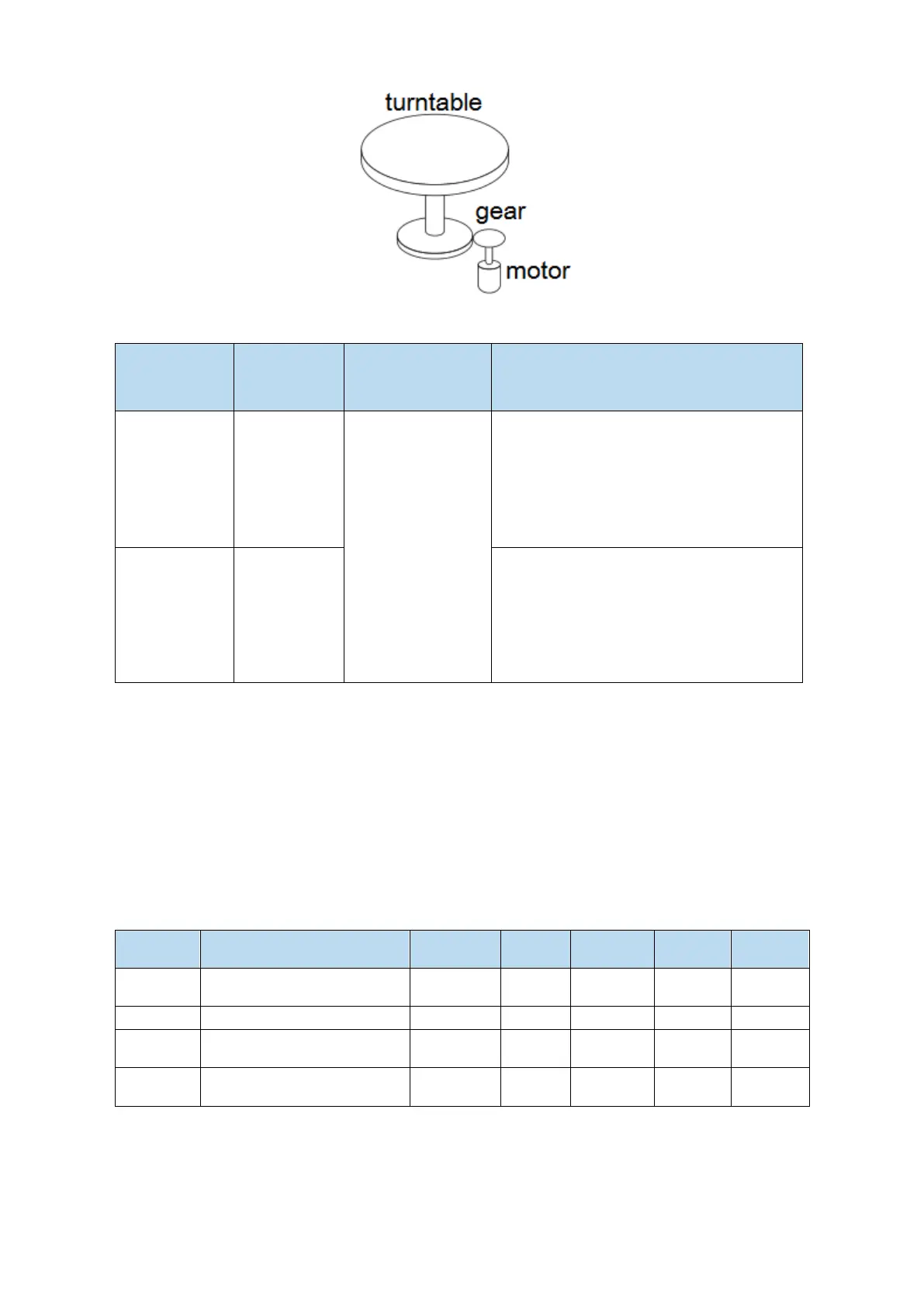

Resolution

(single-circle

data)

Rotating Circle

Serial Data

When it is higher than the upper limit value

in the forward direction (+32767*2^ 17):

Rotation serial data = 32767*2^17

When it is below the lower limit of reversal

direction (-32768*2^ 17):

Rotation Serial Data=-32767*2^17

When it is higher than the upper limit value

in the forward direction (+32767*2^23):

Rotation serial data = 32767*2^23

When it is below the lower limit of reversal

direction (-32768*2^ 23):

Rotation Serial Data=-32767*2^23

5.7 Auxiliary functions

5.7.1 Anti-blocking protection

Anti-blocking alarm: When the motor speed is lower than P0-75 (unit 1 rpm) and the duration reaches

the set value of P0-74 (unit ms), the current output torque U0-02 is greater than the internal positive

torque limit of P3-38 and the internal reverse torque limit of P3-39, it will show the alarm E-165

blocking overtime.

Related parameters

Anti-blocking alarm internal

forward torque limit

Anti-blocking alarm internal

reverse torque limit

Note:

(1) When P0-74 or P0-75 is set to 0, this alarm will not be detected;

(2) If this alarm occurs during normal operation of servo, please confirm:

(a) Monitor U0-02 motor torque and check if P3-38 and P3-39 torque limits are set properly;

(b) Check the external mechanical structure and installation;

(3) P0-74 the default value of locked rotor alarm time is as follows:

Loading...

Loading...