<3. INSTALLATION>

3-1

IM 01E30D01-01EN

3. INSTALLATION

3.1 Piping Design Precautions

WARNING

Installationofthemagneticowmetermust

be performed by expert engineer or skilled

personnel. No operator shall be permitted to

perform procedures relating to installation.

IMPORTANT

Design piping correctly, read the following to

preventdamagetoowtubesandtoassure

accurate measuring.

(1) Location

IMPORTANT

Installtheowmeterinalocationwhereitis

not exposed to direct sunlight. The minimum

ambient temperature is limited by the minimum

uidtemperatureoftheowtube.Formore

information,readChapter12.Theowmeter

may be used in an ambient humidity where

the relative humidity ranges from 0 to 100%.

However, avoid long-term continuous operation

at relative humidity above 95%.

(2) Noise Avoidance

IMPORTANT

Theowmetershouldbeinstalledawayfrom

electrical motors, transformers, inverters

and other power sources in order to avoid

interference with measurement.

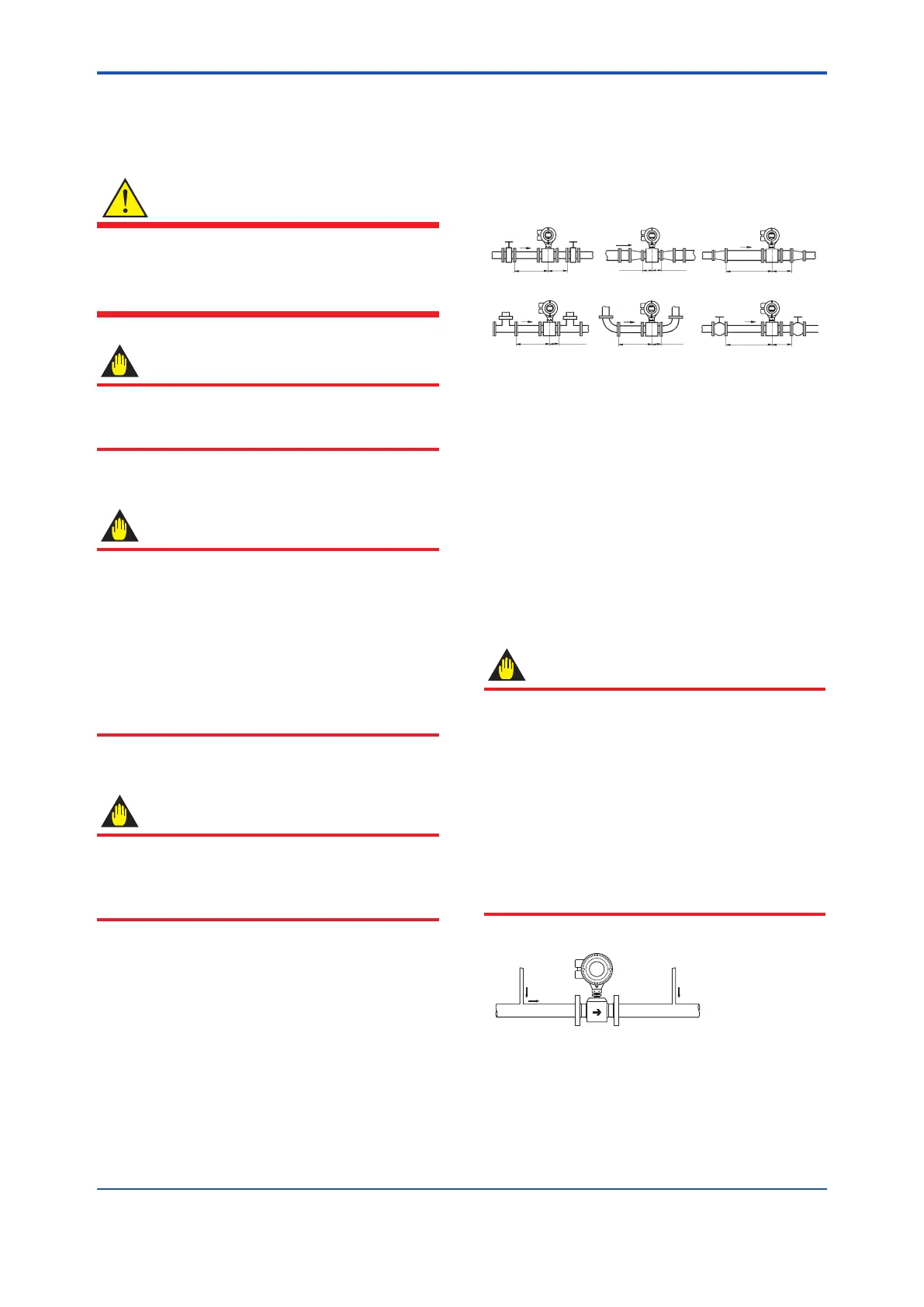

(3) Required Lengths of Straight Runs

To maintain accurate measurement, read JIS B

7554 which explains the requirements for upstream

pipingconditionsofmagneticowmeter.

The piping conditions we recommend as shown in

Figure 3.1.1 are based on JIS B7554 and on our

piping condition test data.

This is not always enough when the piping line

incorporates multiple conditions at the same time.

Wheninstallingtwoormoremagneticowmeteron

a single pipe, provide a run of at least 5D between

them.

Gate valve

fully open

Reducer

pipe

5 D or more

2 D or more

2 D or more

2 D or more

10 D or more

10 D or more

5 D or more

5 D or more

0 is allowable

0 is allowable

0 is allowable

0 is allowable

F0301.ai

Tee

90-degree bent

Various valves

Expander

pipe

Figure 3.1.1 Required Lengths of Straight Runs

*1: Do not install anything in the vicinity that may interfere

withthemagneticeld,inducedsignalvoltages,orow

velocitydistributionsoftheowmeter.

*2: A straight run may not be required on the downstream

sideoftheowmeter.However,ifadownstreamvalve

orotherttingcausesirregularityordeviationinows,

provide a straight run of 2D to 3D on the downstream side.

*3: Highly recommend to mount valves on the downstream

sidesothatdeviatedowsdonotoccurintheowtube

and to avoid startup from an empty condition.

*4: In case the piping conditions are compounded, install

on the straight pipe section where the upstream part is

sufcientlyrectied.

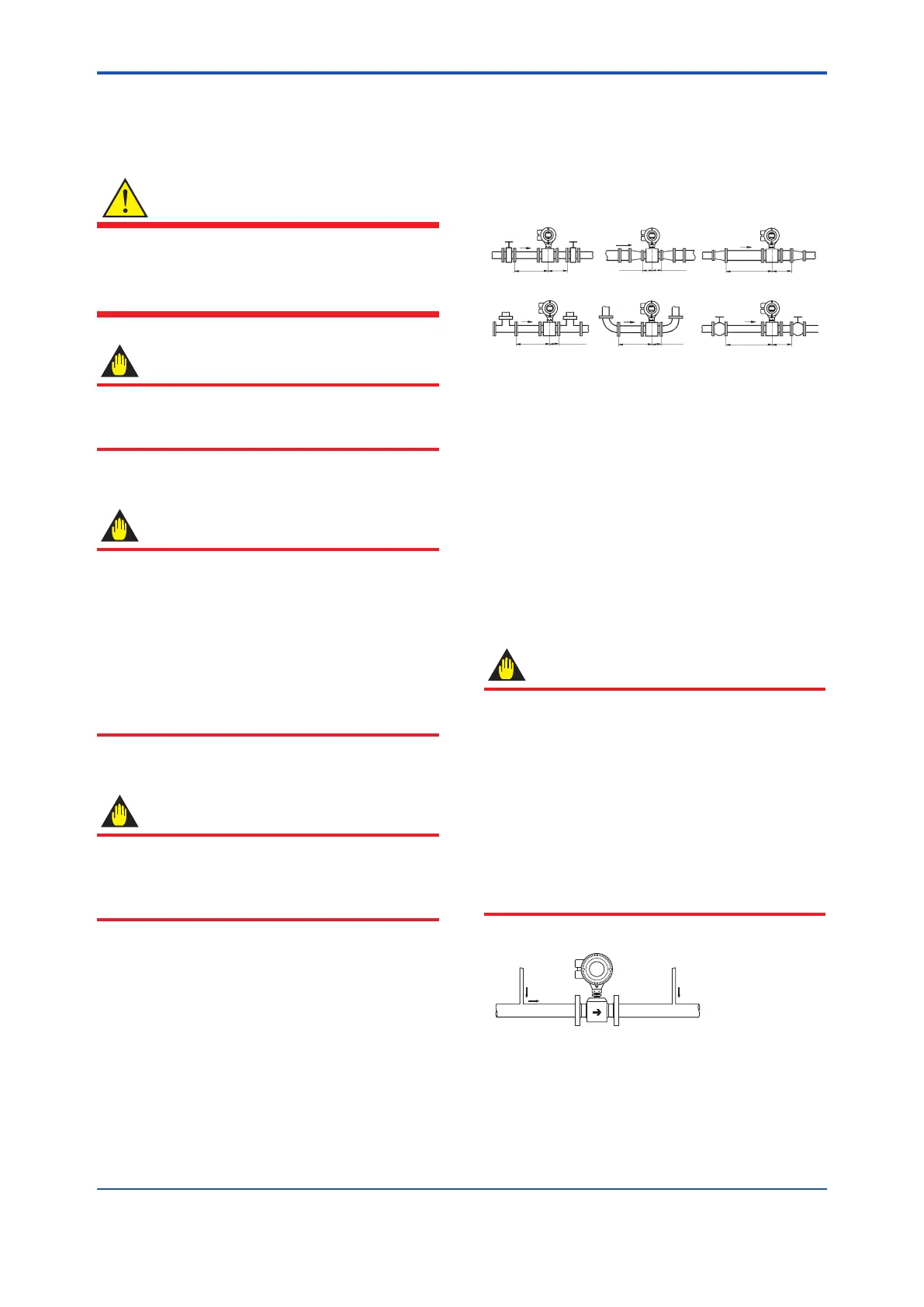

(4) Maintaining Stable Fluid Conductivity

IMPORTANT

Donotinstalltheowmeterwhereuid

conductivity tends to become uneven. If

chemicals are fed near the upstream side of a

magneticowmeter,theymayaffecttheow

rate’s indications. To avoid this situation, it is

recommended that the chemical feed ports be

locatedonthedownstreamsideoftheowmeter.

If it is unavoidable that chemicals must be fed

ontheupstreamside,provideasufcientlength

of straight run (approximately 50D or more) to

ensurethepropermixtureofuids.

F0302.EPS

(Incorrect)

Upstream side

(Correct)

Downstream side

Figure 3.1.2 Chemical Injection

Loading...

Loading...