<11. MAINTENANCE>

11-9

IM 01E30D01-01EN

11.5 Regular Inspection Items

(1) Inspectionofmoisture-proonginsidethe

terminal box: Once/year

(2) Retightening of piping joint screws: About twice/

year

(3) Inspection of electrodes and lining (in case of

adhesiveand/orabrasiveuids,etc.)

Determine the period of regular inspection as

necessary.

11.6 Insulation Resistance Test,

Dielectric Strength Test

NOTE

Note the following precautions when conducting

the insulation resistance test and dielectric

strength test.

(1) Conduct these tests as necessary minimum.

Applying the test voltage may deteriorate the

insulation and safety of the instrument, even

if the overvoltage is far below the insulation

breakdown level.

(2) The voltage for the insulation resistance test

must be 500 V DC or less (100 V DC or less

for the optional code A). The voltage for the

dielectric strength test must be 500 V AC or

less (100 V AC or less for the optional code A).

(3) The test procedures are as follows. Be sure

to disconnect all the wiring before the tests.

11.6.1

Procedure of Insulation Resistance test

(1) Individually, short-circuit the power supply

terminals (SUPPLY+ and SUPPLY-) and digital

output terminals (DO+ and DO-), and connect

the insulation resistance tester (Power OFF) to

the functional grounding terminal..

The polarity between the power supply and

the current output terminal or the digital output

terminal must become a positive pole.

(2) ApplytheDCvoltagespeciedinTable11.6.1

between above-mentioned terminal and the

functional grounding terminal.

The voltage impression time should be a period

whilethetestresultcouldreachfulllingthe

standard.

(3) Afterinspection,insertaresister(100kΩ,

1/2W) between the terminals and discharge for

approximately one second. Never touch the

terminals with bare hands during discharge.

Furthermore, never short-discharge without

inserting a resister.

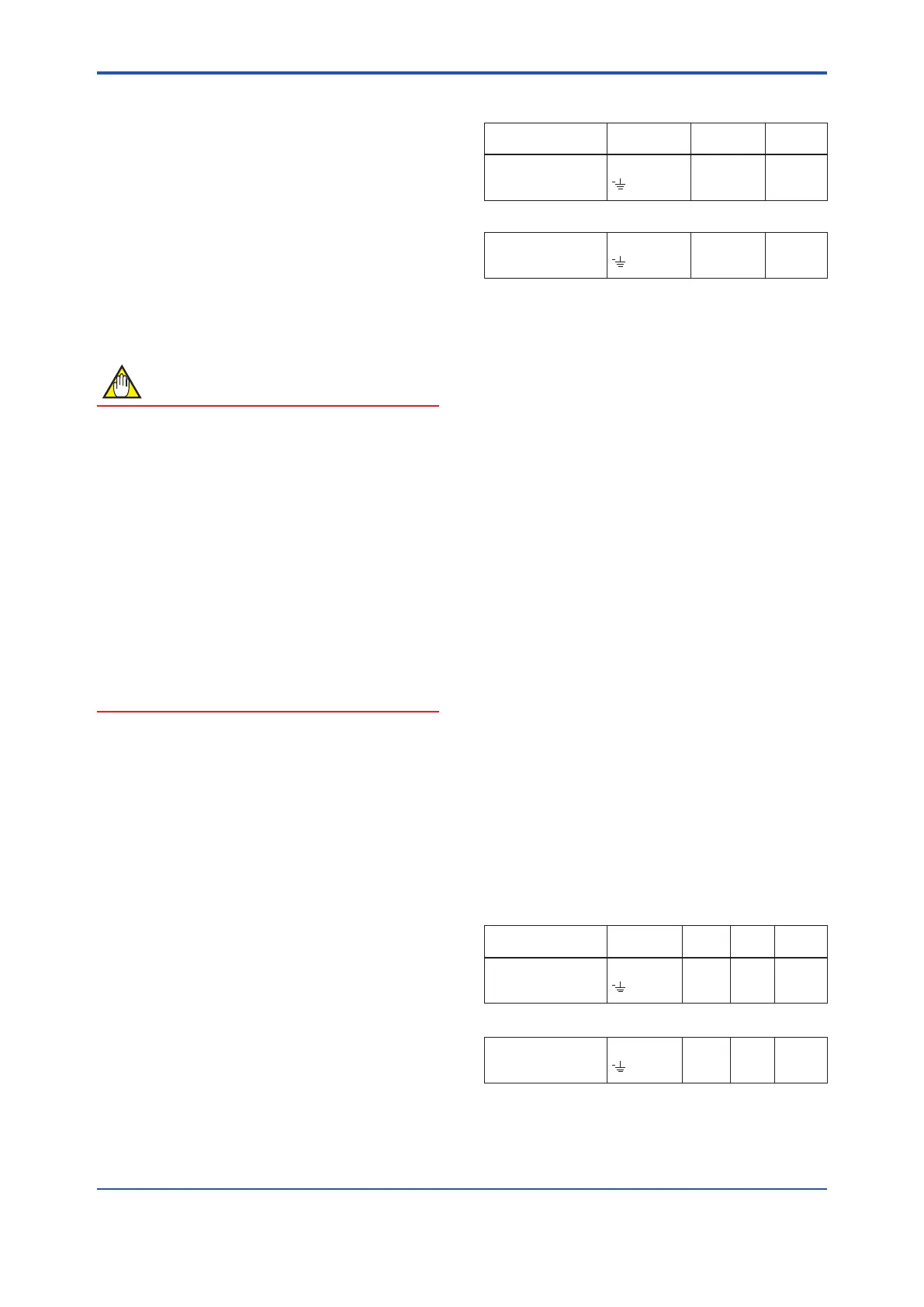

Table 11.6.1 Test terminal for insulation resistance

test

Inspection location Terminal

Test

voltage

Standard

Power Supply/Digital

Output - Functional

Grounding

SUPPLY/DO

500 V DC

100MΩ

or more

When the optional code A is selected (with the lightning

protector), values are as follows.

Power Supply/Digital

Output - Functional

Grounding

SUPPLY/DO

100 V DC

20MΩ

or more

11.6.2 Procedure of Dielectric Strength Test

(1) Individually, short-circuit the power supply

terminals (SUPPLY+ and SUPPLY-) and digital

output terminals (DO+ and DO-), and connect

the dielectric strength tester (Power OFF)

to the functional grounding terminal. Set the

current limitation value as 20 mA in the tester.

The polarity between the power supply and

the current output terminal or the digital output

terminal must become a positive pole.

(2) ApplytheACvoltagespeciedinTable11.6.2,

which approximates a sinusoidal wave form (50

Hz or 60 Hz), between the above mentioned

terminal and the functional grounding terminal.

The AC voltage should be given from 0V to

theinspectionvoltagespeciedinTable11.6.2

gradually.

(3) Keep one minute under the inspection voltage,

andconrmfulllingthestandardorlessofthe

tester.

(4) Decrease the voltage slowly so as not to

generate the voltage serge after the test ends.

(5) Afterinspection,insertaresister(100kΩ,1/2W)

between the terminals and discharge for

approximately one second. Never touch the

terminals with bare hands during discharge.

Furthermore, never short-discharge without

inserting a resister.

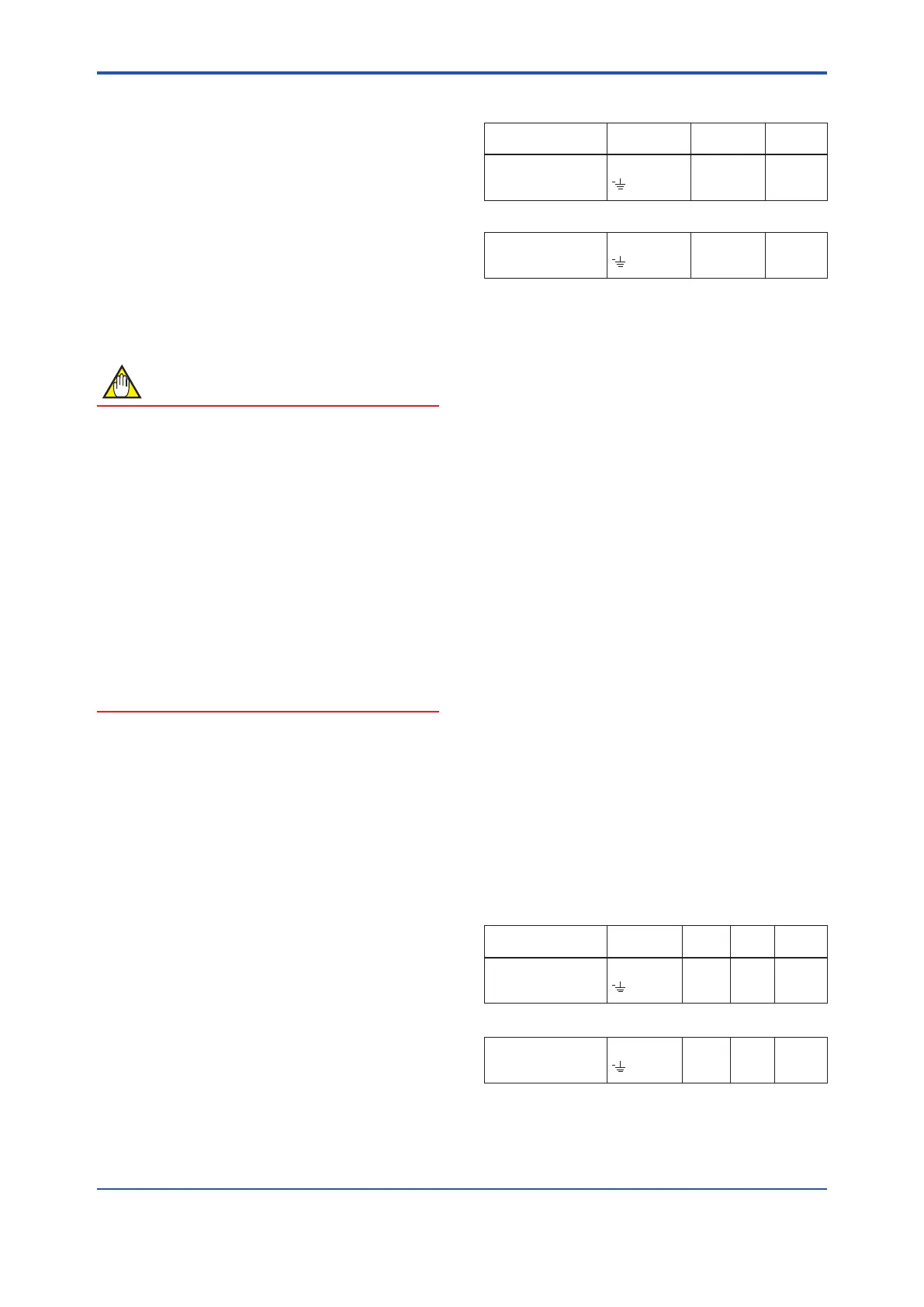

Table 11.6.2 Test terminal for dielectric strength test

Inspection location Terminal

Test

voltage

Test

time

Standard

Power Supply/Digital

Output - Functional

Grounding

SUPPLY/DO

500 V

AC

1 min.

25 mA

or less

When the optional code A is selected (with the lightning

protector), values are as follows.

Power Supply/Digital

Output - Functional

Grounding

SUPPLY/DO

100 V

AC

1 min.

6 mA

or less

Loading...

Loading...