Loading...

Loading...

Do you have a question about the York YR and is the answer not in the manual?

| Brand | York |

|---|---|

| Model | YR |

| Category | Industrial Equipment |

| Language | English |

Explains hazard symbols used in the manual for safe operation and identification.

Details on how the document content may change without notice for product improvement.

Records technical information and other changes made to the document.

Lists related forms and documents for further system information.

Describes a proactive maintenance program leveraging real-time data for optimal operation.

Explains the YORK Model YR Chiller's components and refrigeration cycle.

Details how the chiller manages output via slide valve for load conditions.

Covers chiller start-up sequences, shutdowns, and service technician procedures.

Overview of the control system, interface conventions, access levels, and navigation.

Details on Home, System, Evaporator, Condenser, and Compressor screens.

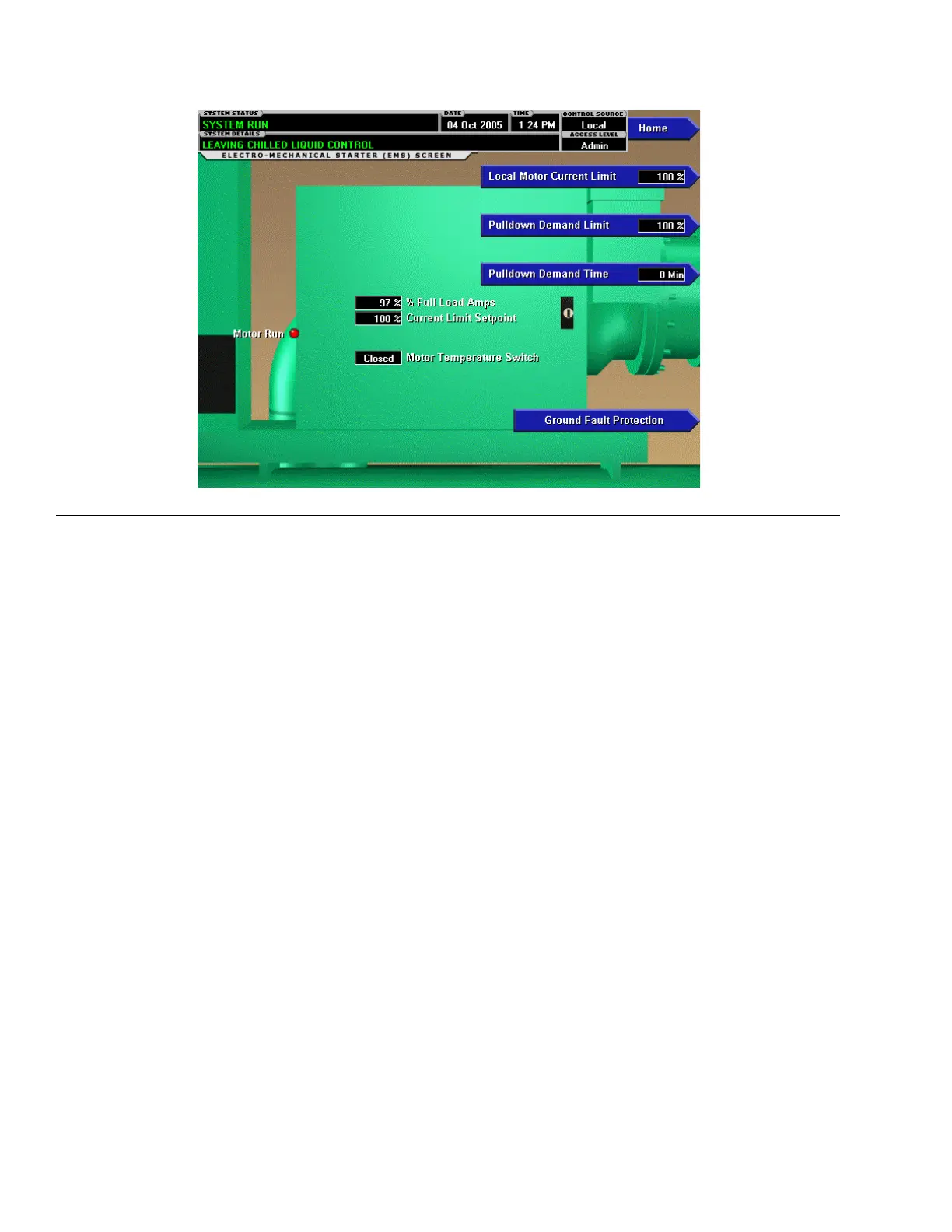

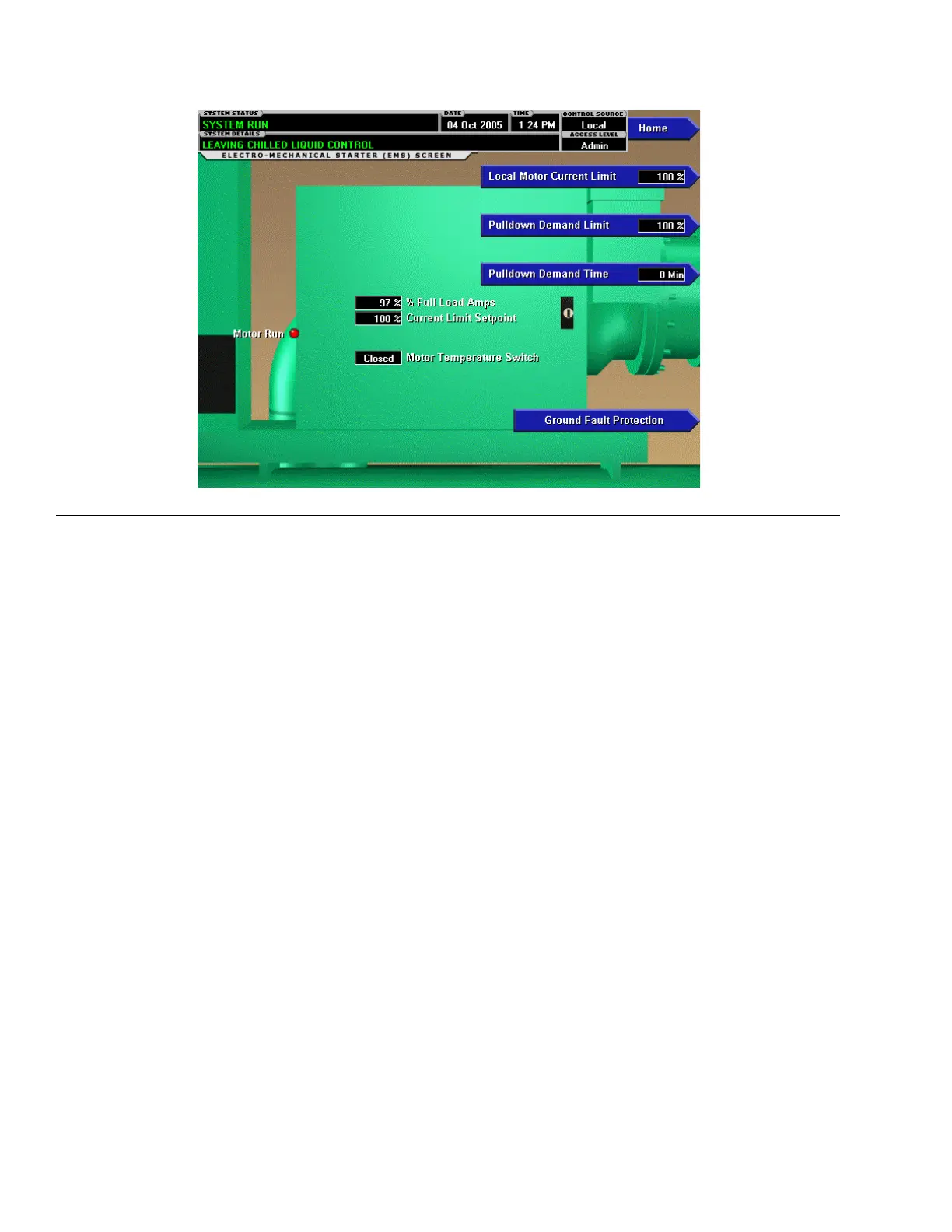

Covers Sensitivity, Hot Gas Bypass, Oil Separator, Starter, and Ground Fault screens.

Screens for managing setpoints, system setup, schedules, users, and communications.

Features for viewing history, security logs, trending data, and custom views.

Describes chiller status, startup sequences, and routine shutdown causes.

Alerts for conditions like clock failure, pressure limits, and startup prevention.

Details critical faults for Evaporator, Condenser, Oil, and Motor systems.

Lists available print reports and compatible printer models (Okidata, Weigh-Tronix, Seiko).

Details physical connections and configuration settings for printers.

Provides factors for converting English units to SI Metric values, including temperature.